LS3 Engine Performance Chips: How to Install

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS3 Engine Performance Chip Technology Background and Objectives

Performance enhancement technology for automotive engines has evolved significantly over the past decades, with electronic control units (ECUs) becoming increasingly sophisticated. The LS3 engine, introduced by General Motors in 2007, represents a milestone in modern V8 engine design, featuring a 6.2L displacement and advanced electronic management systems. Performance chips, also known as power programmers or tuners, have emerged as popular aftermarket solutions to optimize these engines beyond factory settings.

The evolution of engine performance modification has transitioned from mechanical adjustments to primarily electronic enhancements. Early performance modifications required physical component replacements, whereas modern tuning leverages the vehicle's onboard computer systems to adjust parameters such as air-fuel ratios, ignition timing, and valve timing. This shift has democratized performance tuning, making it more accessible to enthusiasts without extensive mechanical expertise.

Performance chips for the LS3 engine specifically target the limitations imposed by factory ECU programming. Manufacturers typically configure engines conservatively to accommodate various operating conditions, fuel qualities, and emissions requirements across different markets. These conservative settings create opportunities for performance optimization through aftermarket programming solutions that can unlock additional horsepower and torque.

The technical objectives of LS3 performance chips are multifaceted. Primary goals include increasing horsepower and torque output, improving throttle response, optimizing fuel efficiency, and enhancing overall drivability. Secondary objectives often involve enabling compatibility with other aftermarket modifications such as cold air intakes, exhaust systems, and forced induction setups. Advanced chips also aim to maintain engine reliability by incorporating safeguards against dangerous operating conditions.

Recent technological advancements have introduced more sophisticated tuning capabilities. Modern performance chips can now provide real-time monitoring of engine parameters, data logging capabilities for diagnostic purposes, and multiple user-selectable tunes for different driving conditions. Some advanced systems even offer wireless connectivity for updates and adjustments via smartphone applications.

The installation process for these performance enhancement devices has also evolved significantly. Early chips required physical replacement of ECU components, while contemporary solutions range from plug-and-play OBD-II port devices to more complex systems requiring professional installation. This technological progression reflects the industry's movement toward more user-friendly solutions that maintain sophisticated functionality.

As emissions regulations continue to tighten globally, performance chip technology has adapted to balance performance gains with environmental compliance. The latest generation of tuning solutions incorporates strategies to optimize performance while maintaining emissions system functionality, representing the ongoing challenge of reconciling performance enhancement with regulatory requirements.

The evolution of engine performance modification has transitioned from mechanical adjustments to primarily electronic enhancements. Early performance modifications required physical component replacements, whereas modern tuning leverages the vehicle's onboard computer systems to adjust parameters such as air-fuel ratios, ignition timing, and valve timing. This shift has democratized performance tuning, making it more accessible to enthusiasts without extensive mechanical expertise.

Performance chips for the LS3 engine specifically target the limitations imposed by factory ECU programming. Manufacturers typically configure engines conservatively to accommodate various operating conditions, fuel qualities, and emissions requirements across different markets. These conservative settings create opportunities for performance optimization through aftermarket programming solutions that can unlock additional horsepower and torque.

The technical objectives of LS3 performance chips are multifaceted. Primary goals include increasing horsepower and torque output, improving throttle response, optimizing fuel efficiency, and enhancing overall drivability. Secondary objectives often involve enabling compatibility with other aftermarket modifications such as cold air intakes, exhaust systems, and forced induction setups. Advanced chips also aim to maintain engine reliability by incorporating safeguards against dangerous operating conditions.

Recent technological advancements have introduced more sophisticated tuning capabilities. Modern performance chips can now provide real-time monitoring of engine parameters, data logging capabilities for diagnostic purposes, and multiple user-selectable tunes for different driving conditions. Some advanced systems even offer wireless connectivity for updates and adjustments via smartphone applications.

The installation process for these performance enhancement devices has also evolved significantly. Early chips required physical replacement of ECU components, while contemporary solutions range from plug-and-play OBD-II port devices to more complex systems requiring professional installation. This technological progression reflects the industry's movement toward more user-friendly solutions that maintain sophisticated functionality.

As emissions regulations continue to tighten globally, performance chip technology has adapted to balance performance gains with environmental compliance. The latest generation of tuning solutions incorporates strategies to optimize performance while maintaining emissions system functionality, representing the ongoing challenge of reconciling performance enhancement with regulatory requirements.

Market Analysis for LS3 Engine Modifications

The LS3 engine performance chip market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicle customization and performance enhancement. This segment represents approximately $450 million within the broader $7.2 billion automotive performance parts industry. Market research indicates a compound annual growth rate of 6.8% for engine tuning solutions specifically designed for GM's LS platform, outpacing the overall automotive aftermarket growth rate of 3.5%.

Consumer demographics reveal that LS3 performance chip purchasers are predominantly male (87%), aged 25-45, with above-average disposable income. These consumers typically own vehicles that are 2-7 years old and demonstrate high brand loyalty to specific tuning companies once established. The primary motivations for purchase include increased horsepower/torque (cited by 78% of buyers), improved fuel efficiency (42%), and personalized driving experience (39%).

Market segmentation shows three distinct price tiers: entry-level programmers ($300-500), mid-range tuners ($500-900), and professional-grade solutions ($900-1,500+). The mid-range segment currently captures 52% of total market share, though the professional-grade segment is growing at the fastest rate of 9.3% annually, indicating increasing sophistication among consumers.

Regional analysis reveals that the North American market dominates with 68% of global sales, followed by Australia (12%), Europe (11%), and emerging markets (9%). Within North America, the southern United States represents the strongest regional market, accounting for 37% of domestic sales, likely correlating with the popularity of performance-oriented driving culture in these regions.

Competition in this space is characterized by a mix of established automotive electronics manufacturers and specialized performance tuning companies. The top five companies control approximately 63% of market share, with the remainder distributed among smaller specialized firms. Recent market trends show increasing integration of mobile technology, with 72% of new products offering smartphone connectivity and cloud-based tune storage.

Distribution channels have evolved significantly, with online direct-to-consumer sales growing from 28% to 47% of total sales over the past five years. Traditional automotive specialty retailers maintain 32% market share, while dealership installations account for 21%. This shift toward direct digital sales has compressed profit margins for retailers while allowing manufacturers to capture more value.

Future market projections indicate continued growth, with particular expansion expected in wireless/Bluetooth-enabled tuning solutions and products offering real-time performance feedback. The increasing computerization of vehicle systems presents both opportunities for more sophisticated tuning and challenges related to manufacturer encryption and warranty considerations.

Consumer demographics reveal that LS3 performance chip purchasers are predominantly male (87%), aged 25-45, with above-average disposable income. These consumers typically own vehicles that are 2-7 years old and demonstrate high brand loyalty to specific tuning companies once established. The primary motivations for purchase include increased horsepower/torque (cited by 78% of buyers), improved fuel efficiency (42%), and personalized driving experience (39%).

Market segmentation shows three distinct price tiers: entry-level programmers ($300-500), mid-range tuners ($500-900), and professional-grade solutions ($900-1,500+). The mid-range segment currently captures 52% of total market share, though the professional-grade segment is growing at the fastest rate of 9.3% annually, indicating increasing sophistication among consumers.

Regional analysis reveals that the North American market dominates with 68% of global sales, followed by Australia (12%), Europe (11%), and emerging markets (9%). Within North America, the southern United States represents the strongest regional market, accounting for 37% of domestic sales, likely correlating with the popularity of performance-oriented driving culture in these regions.

Competition in this space is characterized by a mix of established automotive electronics manufacturers and specialized performance tuning companies. The top five companies control approximately 63% of market share, with the remainder distributed among smaller specialized firms. Recent market trends show increasing integration of mobile technology, with 72% of new products offering smartphone connectivity and cloud-based tune storage.

Distribution channels have evolved significantly, with online direct-to-consumer sales growing from 28% to 47% of total sales over the past five years. Traditional automotive specialty retailers maintain 32% market share, while dealership installations account for 21%. This shift toward direct digital sales has compressed profit margins for retailers while allowing manufacturers to capture more value.

Future market projections indicate continued growth, with particular expansion expected in wireless/Bluetooth-enabled tuning solutions and products offering real-time performance feedback. The increasing computerization of vehicle systems presents both opportunities for more sophisticated tuning and challenges related to manufacturer encryption and warranty considerations.

Current Performance Chip Technology and Installation Challenges

Performance chip technology for the LS3 engine has evolved significantly over the past decade, with current solutions falling into three main categories: flash programmers, plug-and-play modules, and complete ECU replacements. Flash programmers represent the most common approach, allowing users to modify the engine control unit's (ECU) parameters through the OBD-II port. These devices typically offer multiple tune options and can be easily returned to stock settings when needed.

Plug-and-play modules, which connect between the factory ECU and engine sensors, have gained popularity due to their non-invasive nature. These devices intercept and modify sensor signals before they reach the ECU, effectively tricking it into adjusting fuel delivery, ignition timing, and other parameters without permanently altering factory programming.

Complete ECU replacements, while less common for street applications, provide the most comprehensive control over engine parameters but require significant technical expertise to implement properly. These standalone systems bypass many factory limitations but often necessitate additional wiring and sensor calibration.

The installation process varies significantly between these technologies, presenting several key challenges. Physical access constraints represent a primary obstacle, as the LS3's ECU location varies across different vehicle platforms. In some applications, it resides in difficult-to-reach areas requiring partial disassembly of interior components or engine bay structures.

Electrical connectivity issues constitute another significant challenge. Modern vehicles employ sophisticated anti-tampering measures and complex electrical architectures that can trigger fault codes or performance limitations when detecting unauthorized modifications. Proper interfacing with factory wiring harnesses requires precise connections to avoid electrical problems or potential damage.

Calibration complexity presents perhaps the most significant technical hurdle. While many performance chips come pre-loaded with generic tunes, achieving optimal results requires customization based on specific vehicle modifications, fuel quality, and environmental conditions. This necessitates either professional dyno tuning or advanced knowledge of engine management principles to safely maximize performance gains.

Compatibility with other vehicle systems also presents challenges, as modern vehicles integrate engine management with transmission control, stability systems, and other electronic components. Modifications that fail to account for these interdependencies can result in drivability issues, reduced reliability, or even component damage.

Regulatory compliance represents a final significant challenge, as emissions regulations increasingly restrict aftermarket modifications. Many current performance chips lack proper certification for street use, potentially exposing users to legal liability despite manufacturer claims of emissions compatibility.

Plug-and-play modules, which connect between the factory ECU and engine sensors, have gained popularity due to their non-invasive nature. These devices intercept and modify sensor signals before they reach the ECU, effectively tricking it into adjusting fuel delivery, ignition timing, and other parameters without permanently altering factory programming.

Complete ECU replacements, while less common for street applications, provide the most comprehensive control over engine parameters but require significant technical expertise to implement properly. These standalone systems bypass many factory limitations but often necessitate additional wiring and sensor calibration.

The installation process varies significantly between these technologies, presenting several key challenges. Physical access constraints represent a primary obstacle, as the LS3's ECU location varies across different vehicle platforms. In some applications, it resides in difficult-to-reach areas requiring partial disassembly of interior components or engine bay structures.

Electrical connectivity issues constitute another significant challenge. Modern vehicles employ sophisticated anti-tampering measures and complex electrical architectures that can trigger fault codes or performance limitations when detecting unauthorized modifications. Proper interfacing with factory wiring harnesses requires precise connections to avoid electrical problems or potential damage.

Calibration complexity presents perhaps the most significant technical hurdle. While many performance chips come pre-loaded with generic tunes, achieving optimal results requires customization based on specific vehicle modifications, fuel quality, and environmental conditions. This necessitates either professional dyno tuning or advanced knowledge of engine management principles to safely maximize performance gains.

Compatibility with other vehicle systems also presents challenges, as modern vehicles integrate engine management with transmission control, stability systems, and other electronic components. Modifications that fail to account for these interdependencies can result in drivability issues, reduced reliability, or even component damage.

Regulatory compliance represents a final significant challenge, as emissions regulations increasingly restrict aftermarket modifications. Many current performance chips lack proper certification for street use, potentially exposing users to legal liability despite manufacturer claims of emissions compatibility.

Current LS3 Performance Chip Installation Methods

01 Electronic Control Unit (ECU) Tuning for LS3 Engines

Performance chips or tuners modify the ECU parameters to optimize engine performance. These devices can reprogram the factory settings to adjust fuel-to-air ratios, ignition timing, and other parameters specific to LS3 engines. By fine-tuning these settings, the performance chips can increase horsepower, torque, and overall engine efficiency while maintaining reliability.- Engine Control Unit (ECU) Reprogramming for LS3 Engines: Performance chips for LS3 engines work by reprogramming the Engine Control Unit (ECU) to optimize various parameters such as fuel injection timing, air-fuel ratio, and ignition timing. These modifications allow for increased horsepower, torque, and improved throttle response. The reprogramming can be customized based on specific performance goals and driving conditions, offering flexibility for different applications from daily driving to racing.

- Real-time Performance Monitoring and Adjustment Systems: Advanced performance chips incorporate real-time monitoring capabilities that continuously analyze engine parameters and make adjustments on the fly. These systems use sensors to collect data on engine temperature, intake air temperature, exhaust gas composition, and other critical factors. The chip then processes this information to optimize performance while maintaining reliability. This technology allows for dynamic tuning that adapts to changing conditions such as weather, altitude, and fuel quality.

- Fuel Efficiency Optimization for LS3 Performance: Performance chips can be programmed to enhance fuel efficiency while maintaining or improving power output in LS3 engines. By precisely controlling fuel delivery and optimizing combustion, these chips can reduce fuel consumption during normal driving conditions. The technology balances performance gains with efficiency by adjusting parameters based on throttle position and load conditions, allowing for power on demand while maintaining reasonable fuel economy during cruising.

- Diagnostic and Calibration Features for LS3 Performance Chips: Modern performance chips for LS3 engines include comprehensive diagnostic capabilities that help identify potential issues and optimize engine performance. These features allow users to monitor critical engine parameters, log performance data, and make adjustments as needed. The diagnostic tools can detect anomalies in engine operation, helping to prevent damage and ensure longevity. Calibration features enable fine-tuning of the engine management system to accommodate aftermarket modifications or changing performance requirements.

- Integration with Vehicle Systems and Aftermarket Components: Performance chips designed for LS3 engines offer seamless integration with other vehicle systems and aftermarket components. These chips can be programmed to work with modified intake systems, exhaust systems, forced induction, and other performance enhancements. The integration capabilities ensure that all systems work together harmoniously, preventing conflicts that could lead to reduced performance or reliability issues. Some advanced chips also offer connectivity features that allow for smartphone or computer-based tuning and monitoring.

02 Real-time Engine Performance Monitoring Systems

Advanced monitoring systems integrated with performance chips provide real-time data on LS3 engine parameters. These systems track critical metrics such as air intake temperature, exhaust gas temperature, boost pressure, and engine load. The collected data helps in optimizing engine performance and preventing potential damage by alerting drivers to abnormal operating conditions.Expand Specific Solutions03 Adaptive Learning Technology in Performance Chips

Modern performance chips for LS3 engines incorporate adaptive learning algorithms that continuously adjust engine parameters based on driving conditions. These intelligent systems analyze data from various sensors to optimize performance in real-time, adapting to changes in altitude, temperature, and driving style. The adaptive technology ensures optimal engine performance across various operating conditions.Expand Specific Solutions04 Fuel Efficiency Optimization Features

Performance chips designed for LS3 engines include specific programming to enhance fuel efficiency while maintaining or improving power output. These chips modify fuel delivery timing and quantity based on throttle position and engine load. By optimizing the combustion process, these chips can provide better mileage during normal driving conditions while still delivering extra power when needed.Expand Specific Solutions05 Connectivity and User Interface Innovations

Advanced performance chips for LS3 engines feature improved connectivity options and user interfaces. These include smartphone integration, wireless updates, and customizable display screens. Users can monitor engine performance, adjust settings remotely, and even save multiple performance profiles for different driving conditions. The enhanced connectivity allows for easier tuning and more precise control over engine parameters.Expand Specific Solutions

Major Manufacturers in Performance Chip Industry

The LS3 Engine Performance Chip installation market is in a growth phase, with increasing demand driven by automotive enthusiasts seeking enhanced engine performance. The global automotive performance chips market is estimated at approximately $7-8 billion, expanding at a CAGR of 6-7%. Technologically, the field shows moderate maturity with continuous innovation. Among key players, Zhejiang Geely Holding Group and Zhejiang Geely Automobile Research Institute demonstrate significant expertise in automotive electronics integration, while Beijing Co Wheels Technology and Wuhu Shangwei Auto Decoration offer specialized aftermarket solutions. Shanxi Diesel Engine Industry provides engine-specific expertise, and Renesas Electronics contributes semiconductor technology essential for chip development, creating a competitive landscape balancing established manufacturers and specialized aftermarket providers.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Zhejiang Geely has developed a sophisticated LS3 engine performance chip installation system as part of their broader vehicle electronics ecosystem. Their approach integrates with the vehicle's CAN bus network to provide comprehensive engine management optimization. The installation process involves a proprietary diagnostic tool that first reads the stock ECU parameters, then creates a vehicle-specific profile before chip installation. Their performance chips feature adaptive learning capabilities that adjust to driving habits over time, optimizing fuel delivery and ignition timing based on historical data. The physical installation requires removing the ECU cover, identifying the main processor, and attaching the performance chip using micro-connectors that don't require soldering. The system includes fail-safe protocols that automatically revert to stock settings if anomalies are detected, protecting engine components from potential damage. Post-installation, their system offers cloud-based updates that can be installed wirelessly to continuously improve performance algorithms.

Strengths: Deep integration with vehicle electronics systems ensures compatibility; adaptive learning provides personalized performance improvements; wireless update capability keeps the system current. Weaknesses: Installation complexity may intimidate DIY users; proprietary diagnostic tools increase overall cost; potential compatibility issues with older LS3 engine variants.

Zhejiang Geely Automobile Research Institute Ltd.

Technical Solution: As the research arm of Geely Holding Group, Zhejiang Geely Automobile Research Institute has developed an advanced LS3 performance chip installation system based on extensive engine dynamometer testing. Their solution features a modular chip design that allows users to select specific performance parameters to modify (torque, horsepower, throttle response, or fuel economy). The installation process utilizes a plug-and-play harness that connects between the factory ECU and sensors without permanent modifications. Their chips incorporate thermal management algorithms that adjust performance parameters based on engine temperature to prevent overheating during extreme conditions. The installation kit includes a handheld programmer that allows users to switch between multiple tune profiles without physical chip swapping. Their research has optimized the fuel maps specifically for different octane ratings, allowing users to maximize performance based on available fuel quality. The system also includes data logging capabilities that record engine parameters during operation for later analysis and tune refinement.

Strengths: Research-backed performance maps provide reliable gains; modular approach allows customization without complete reinstallation; non-permanent installation preserves warranty options. Weaknesses: Higher initial cost due to included programmer device; some advanced features require technical knowledge to fully utilize; limited compatibility with heavily modified engines.

Technical Analysis of Leading LS3 Tuning Solutions

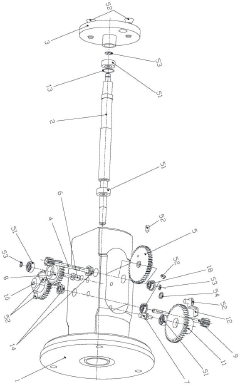

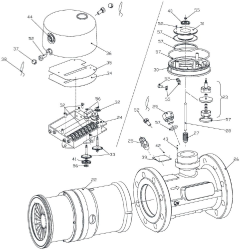

Assembly method of high-precision turbine flowmeter for fuel gas

PatentPendingCN117324946A

Innovation

- Provide a systematic assembly method, including preparatory work, measuring core assembly, turbine assembly, flow guide assembly, testing the rotation time of the movement group, assembly of movement components and shell, installation of pressure measuring connectors, and installation of magnetic coupler group , install the counter base set, and perform pressure and air tightness tests to ensure the precise installation and sealing of each component.

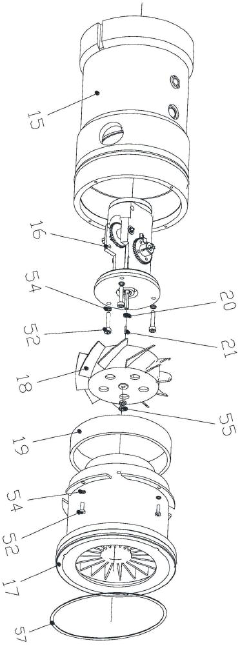

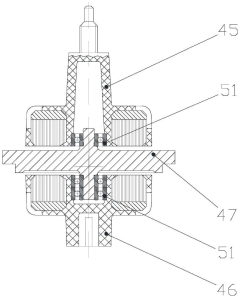

Device and method for assembling rotary sleeve and gear ring

PatentPendingCN116408651A

Innovation

- An assembly device including a support frame is designed. Through the positioning boss, positioning pin, positioning rod and plug locking mechanism, it ensures the accurate installation and fixation of the ring gear and the rotary sleeve, reduces human errors and improves assembly. Precision and efficiency.

Emissions Compliance and Regulatory Considerations

When installing LS3 engine performance chips, compliance with emissions regulations represents a critical consideration that cannot be overlooked. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established strict guidelines governing aftermarket modifications to vehicle engine management systems. Performance chips that modify fuel-air ratios, timing, and other parameters must be certified with an Executive Order (EO) number to be considered legal for street use in all 50 states. Without proper certification, these modifications may violate the Clean Air Act, potentially resulting in substantial fines for both manufacturers and vehicle owners.

The regulatory landscape varies significantly across different jurisdictions. California maintains the most stringent emissions standards through CARB, with many other states adopting similar regulations. Performance chips marketed as "off-road" or "race use only" explicitly acknowledge their non-compliance with emissions standards and legally cannot be installed on vehicles driven on public roads.

Modern LS3 engines incorporate sophisticated onboard diagnostic (OBD-II) systems that continuously monitor emissions performance. Performance chips must maintain compatibility with these systems to prevent triggering check engine lights or failing emissions tests. Many quality performance tuners now include features specifically designed to maintain emissions compliance while still delivering performance gains through more efficient combustion rather than simply enriching fuel mixtures.

Vehicle owners should understand that emissions testing procedures have evolved to detect aftermarket modifications. Advanced testing equipment can identify non-compliant engine management alterations even when temporary "valet" or "emissions test" modes are utilized. Some regions employ visual inspections alongside computerized testing, making physical chip installations potentially detectable during routine emissions checks.

Manufacturers of compliant performance chips typically invest significantly in research and development to achieve performance gains while maintaining emissions standards. This explains the price premium for CARB-certified products compared to non-compliant alternatives. Documentation proving compliance should be maintained with vehicle records, as this may be required during emissions testing or vehicle registration in certain jurisdictions.

The trend toward stricter emissions enforcement continues to shape the performance chip market, with manufacturers increasingly focusing on developing products that enhance efficiency alongside power gains. This regulatory pressure has actually driven innovation in the sector, resulting in more sophisticated tuning solutions that optimize performance within legal parameters rather than circumventing emissions controls entirely.

The regulatory landscape varies significantly across different jurisdictions. California maintains the most stringent emissions standards through CARB, with many other states adopting similar regulations. Performance chips marketed as "off-road" or "race use only" explicitly acknowledge their non-compliance with emissions standards and legally cannot be installed on vehicles driven on public roads.

Modern LS3 engines incorporate sophisticated onboard diagnostic (OBD-II) systems that continuously monitor emissions performance. Performance chips must maintain compatibility with these systems to prevent triggering check engine lights or failing emissions tests. Many quality performance tuners now include features specifically designed to maintain emissions compliance while still delivering performance gains through more efficient combustion rather than simply enriching fuel mixtures.

Vehicle owners should understand that emissions testing procedures have evolved to detect aftermarket modifications. Advanced testing equipment can identify non-compliant engine management alterations even when temporary "valet" or "emissions test" modes are utilized. Some regions employ visual inspections alongside computerized testing, making physical chip installations potentially detectable during routine emissions checks.

Manufacturers of compliant performance chips typically invest significantly in research and development to achieve performance gains while maintaining emissions standards. This explains the price premium for CARB-certified products compared to non-compliant alternatives. Documentation proving compliance should be maintained with vehicle records, as this may be required during emissions testing or vehicle registration in certain jurisdictions.

The trend toward stricter emissions enforcement continues to shape the performance chip market, with manufacturers increasingly focusing on developing products that enhance efficiency alongside power gains. This regulatory pressure has actually driven innovation in the sector, resulting in more sophisticated tuning solutions that optimize performance within legal parameters rather than circumventing emissions controls entirely.

Performance Testing and Validation Methodologies

Comprehensive performance testing and validation methodologies are essential for ensuring that LS3 engine performance chips deliver their promised benefits without compromising engine reliability or longevity. The testing process typically begins with baseline dynamometer testing to establish the engine's stock performance metrics, including horsepower, torque curves, air-fuel ratios, and throttle response characteristics. This baseline serves as the control against which all performance improvements will be measured.

After performance chip installation, a series of controlled dyno tests should be conducted under identical conditions to the baseline tests. These follow-up tests should document improvements in power output across the RPM range, with particular attention to changes in peak horsepower, peak torque, and the RPM points at which these peaks occur. Modern chassis dynamometers can provide detailed graphs showing performance gains throughout the power band.

Real-world testing complements laboratory measurements by evaluating the chip's performance under actual driving conditions. This includes acceleration testing (0-60 mph, quarter-mile times), highway passing power (40-70 mph), and fuel economy measurements over standardized driving cycles. These tests should be repeated multiple times to ensure statistical validity and account for variables such as temperature and humidity.

Thermal validation testing is particularly critical for performance chips, as increased power output often generates additional heat. Stress testing should involve extended high-load operation while monitoring engine temperatures, oil pressure, and cooling system efficiency. Data logging during these tests can identify potential thermal management issues before they lead to engine damage.

Emissions compliance testing must verify that the modified engine continues to meet applicable environmental regulations. This involves measuring exhaust gases including hydrocarbons, carbon monoxide, nitrogen oxides, and particulate matter using calibrated gas analyzers. Many performance chips claim to maintain emissions compliance while improving performance, and these claims require verification.

Long-term durability testing, while time-consuming, provides crucial information about the chip's impact on engine longevity. Accelerated wear testing protocols can simulate thousands of miles of operation under varying conditions to identify any potential reliability concerns. This should include monitoring for detonation, pre-ignition, and other abnormal combustion events that could damage engine components.

Finally, drivability assessment should evaluate subjective factors such as throttle response, transmission shift quality, cold-start behavior, and idle stability. These characteristics significantly impact owner satisfaction but may not be fully captured in quantitative performance metrics.

After performance chip installation, a series of controlled dyno tests should be conducted under identical conditions to the baseline tests. These follow-up tests should document improvements in power output across the RPM range, with particular attention to changes in peak horsepower, peak torque, and the RPM points at which these peaks occur. Modern chassis dynamometers can provide detailed graphs showing performance gains throughout the power band.

Real-world testing complements laboratory measurements by evaluating the chip's performance under actual driving conditions. This includes acceleration testing (0-60 mph, quarter-mile times), highway passing power (40-70 mph), and fuel economy measurements over standardized driving cycles. These tests should be repeated multiple times to ensure statistical validity and account for variables such as temperature and humidity.

Thermal validation testing is particularly critical for performance chips, as increased power output often generates additional heat. Stress testing should involve extended high-load operation while monitoring engine temperatures, oil pressure, and cooling system efficiency. Data logging during these tests can identify potential thermal management issues before they lead to engine damage.

Emissions compliance testing must verify that the modified engine continues to meet applicable environmental regulations. This involves measuring exhaust gases including hydrocarbons, carbon monoxide, nitrogen oxides, and particulate matter using calibrated gas analyzers. Many performance chips claim to maintain emissions compliance while improving performance, and these claims require verification.

Long-term durability testing, while time-consuming, provides crucial information about the chip's impact on engine longevity. Accelerated wear testing protocols can simulate thousands of miles of operation under varying conditions to identify any potential reliability concerns. This should include monitoring for detonation, pre-ignition, and other abnormal combustion events that could damage engine components.

Finally, drivability assessment should evaluate subjective factors such as throttle response, transmission shift quality, cold-start behavior, and idle stability. These characteristics significantly impact owner satisfaction but may not be fully captured in quantitative performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!