Compressor capacity modulation

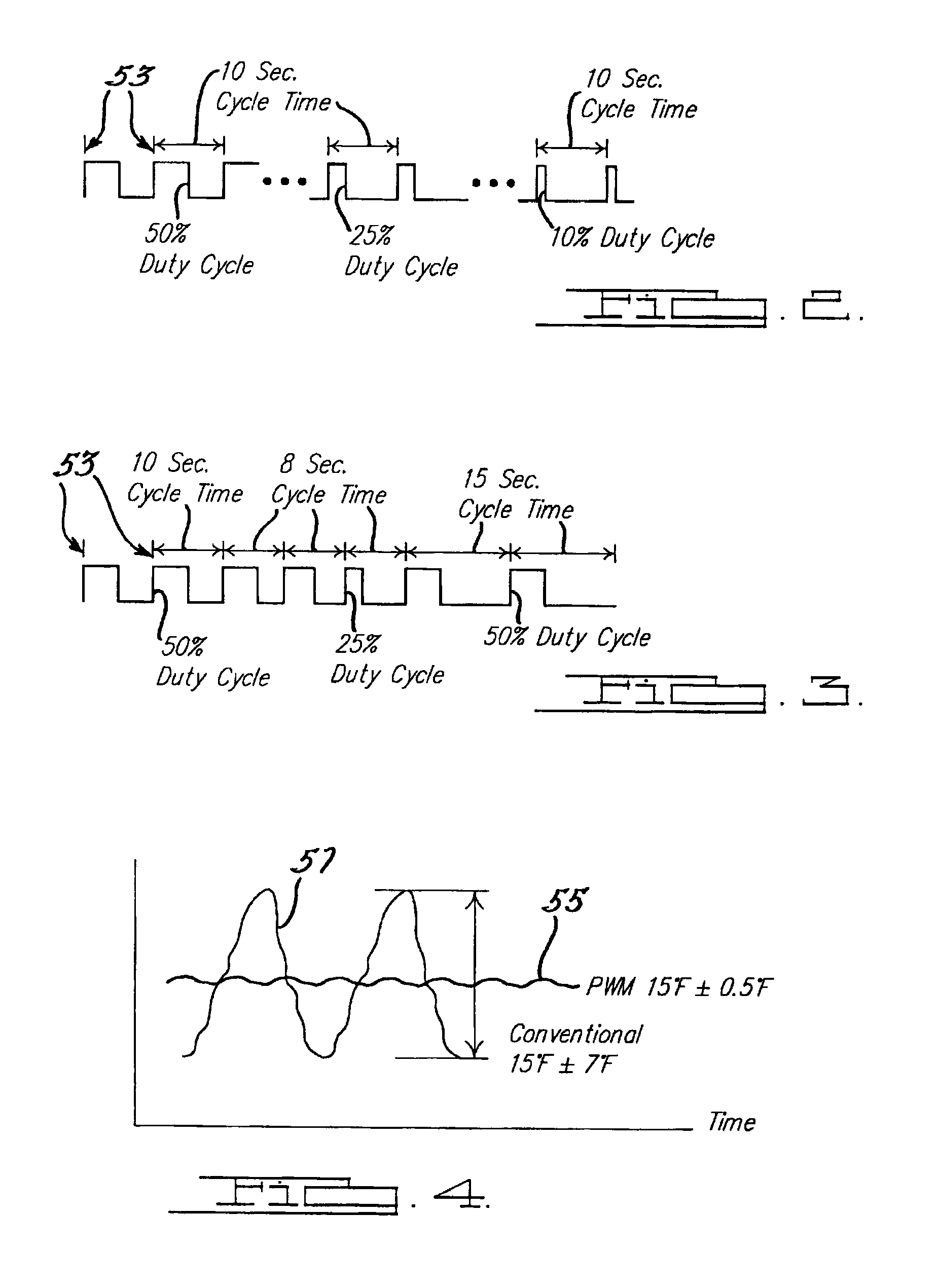

a compressor and capacity technology, applied in the direction of pump parameters, positive displacement liquid engines, lighting and heating apparatus, etc., can solve the problem of inability to maximize the overall operating system efficiency, excess or deficient capacity, and the degree of modulation that can be achieved, so as to reduce the fluctuation of pressure in the refrigerant system, reduce the unbalanced operation of the compressor, and reduce the effect of temperature pull down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

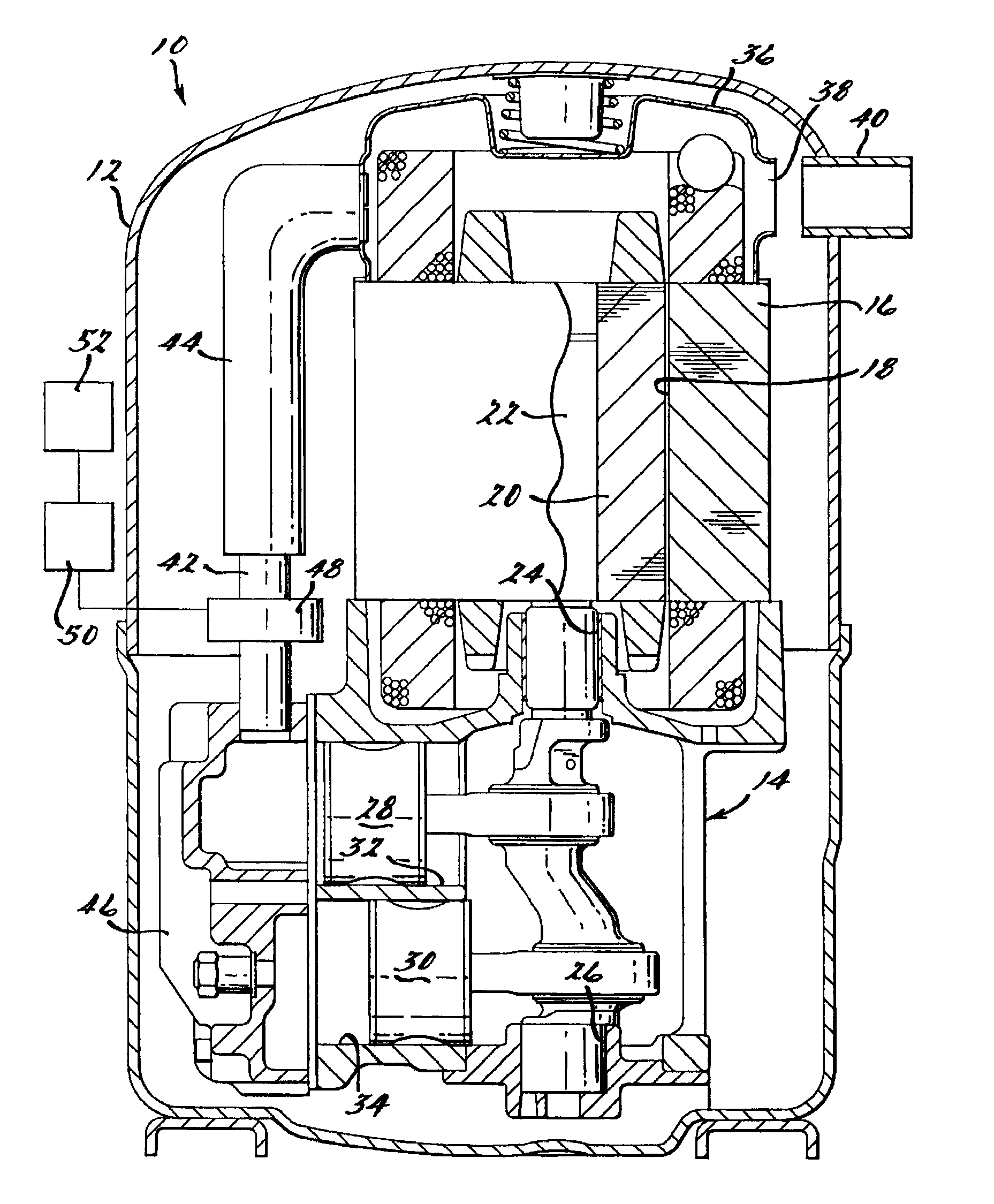

[0024]Referring now to the drawings and more specifically to FIG. 1 there is shown a reciprocating piston type refrigeration compressor 10 comprising an outer shell 12 within which is disposed reciprocating compressor housing 14 on which is mounted an associated driving motor including stator 16 having a bore 18 provided therein. A rotor 20 is disposed within bore 18 being secured to crankshaft 22 which is rotatably supported within housing 14 by upper and lower bearings 24 and 26 respectively. A pair of pistons 28 and 30 are connected to crankshaft 22 and reciprocably disposed in cylinders 32 and 34 respectively. A motor cover 36 is secured in overlying relationship to the upper end of stator 16 and includes an inlet opening 38 aligned with a suction inlet fitting 40 provided through shell 12. A suction muffler 44 is provided on the opposite side of motor cover 36 and serves to direct suction gas from the interior of motor cover 36 to respective cylinders 32, 34 via suction pipe 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com