Process and arrangement for confocal microscopy

a confocal microscopy and confocal light technology, applied in the field of confocal light microscopy, can solve the problems of insufficient, inability to achieve the effect of precise image evaluation, and gain of impression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

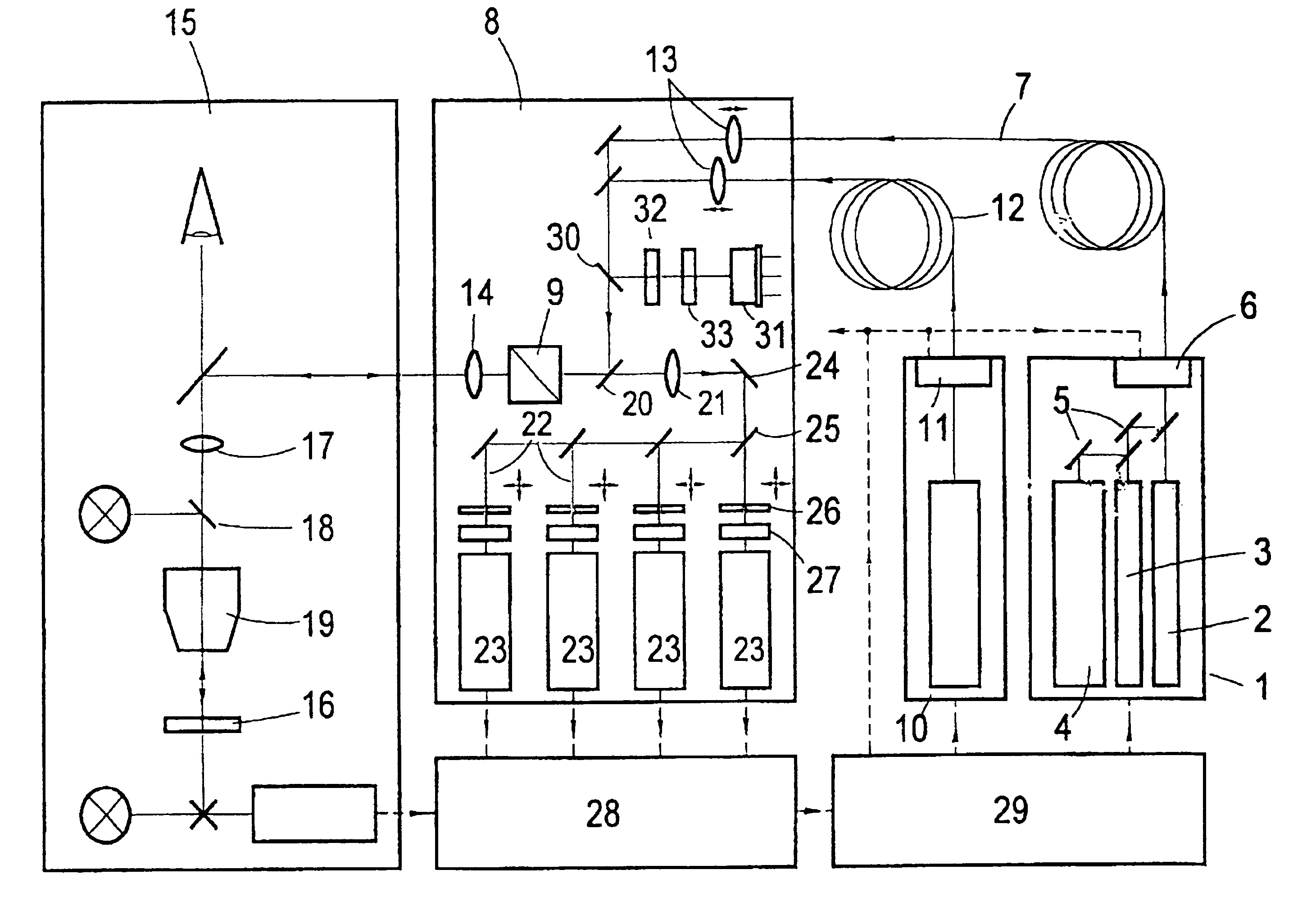

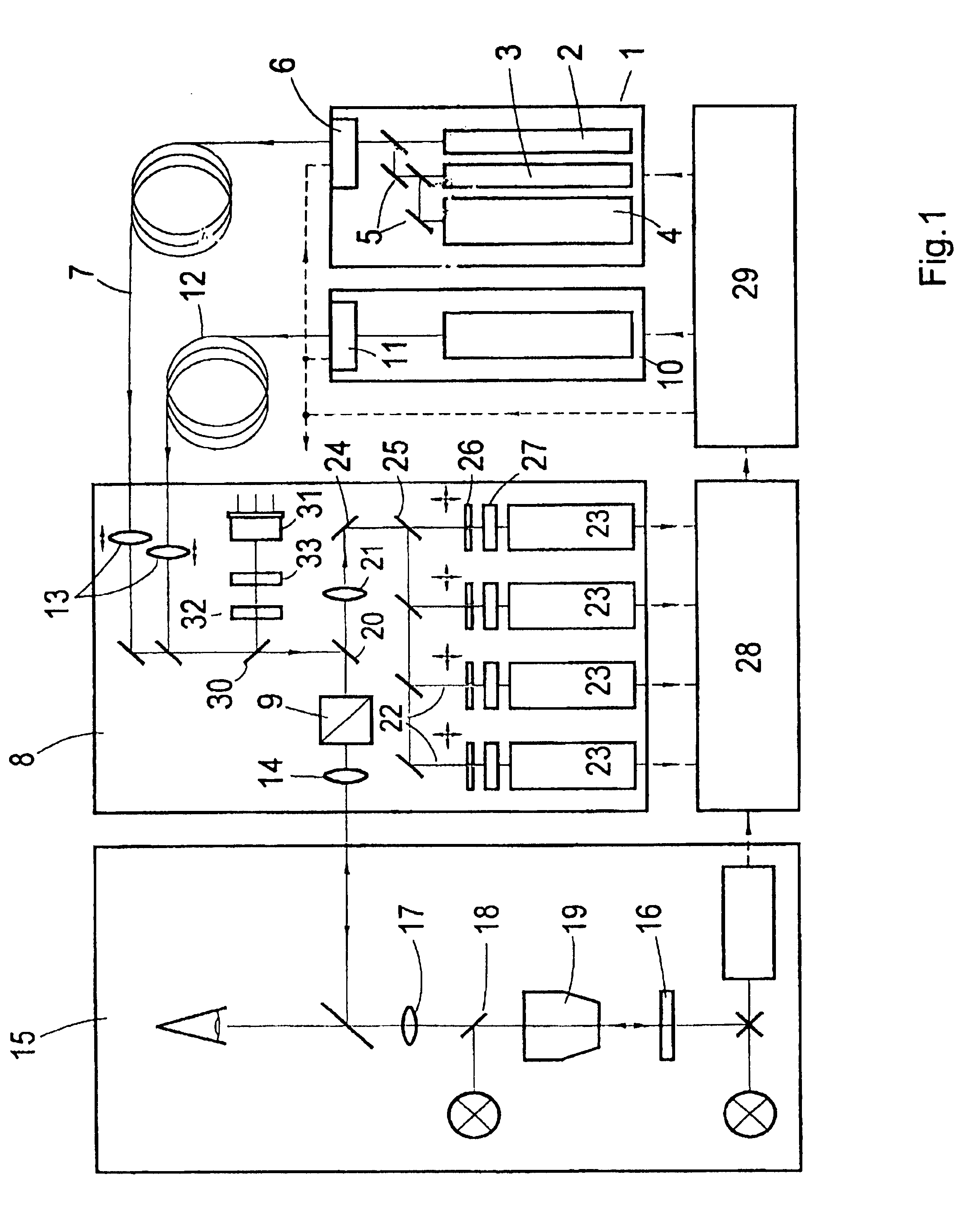

[0041]FIG. 1 shows a laser module 1 which is outfitted with lasers 2, 3 and 4 for generating laser light in the visible range with wavelengths of 633 nm, 543 nm and 458 nm. By mean of a plurality of beam combiners 5, an AOTF 6 and a fiber 7, the radiation emitted by these lasers is coupled into a scanning device 8 which is outfitted with a unit 9 deflecting beams in the x and y coordinates.

[0042]A UV laser whose light is coupled into the scanning device 8 via an AOTF 11 and a light-conducting fiber 12 is provided in a second laser module 10.

[0043]In the two beam paths, collimating optics 13 are provided subsequent to the light-conducting fibers 7 and 12, wherein the distance between the collimating optics 13 and the respective end of the fiber can be changed and the collimating optics 13 are coupled for this purpose with a controllable adjusting device (not shown in the drawing).

[0044]The laser radiation is coupled into the beam path of the schematically shown microscope 15 by the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com