Pulse width modulation circuit controlling output current of an inverter circuit for motor-driven blower or electric vacuum cleaner

a technology of inverter circuit and output current, which is applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, stopping arrangement, etc., can solve the problems of excessive current flow, increase the pulse width, and easily limit or suppress an inrush, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]One embodiment of the present invention will be described.

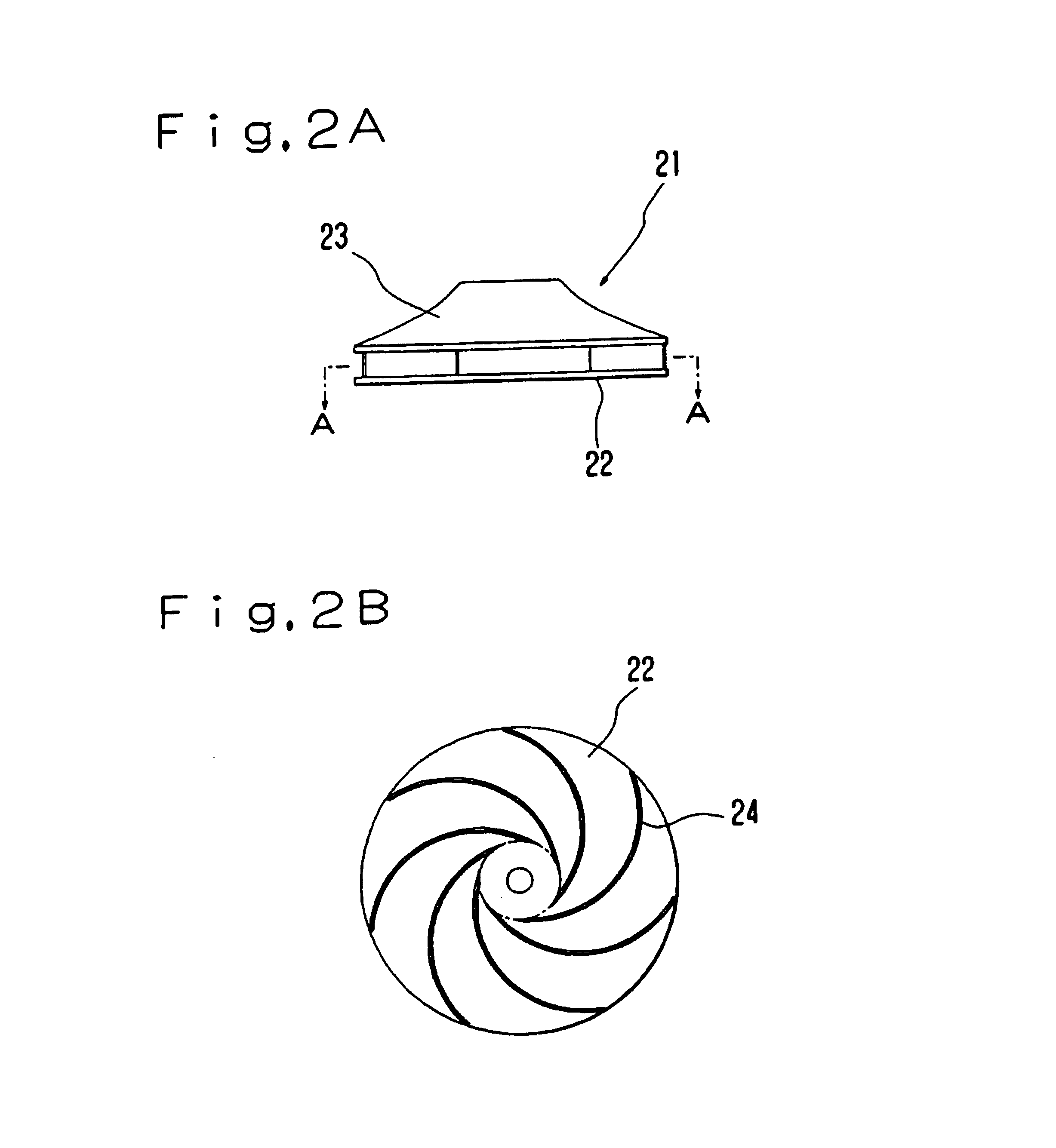

[0027]A motor-driven blower illustrating an embodiment of the present invention will first be described.

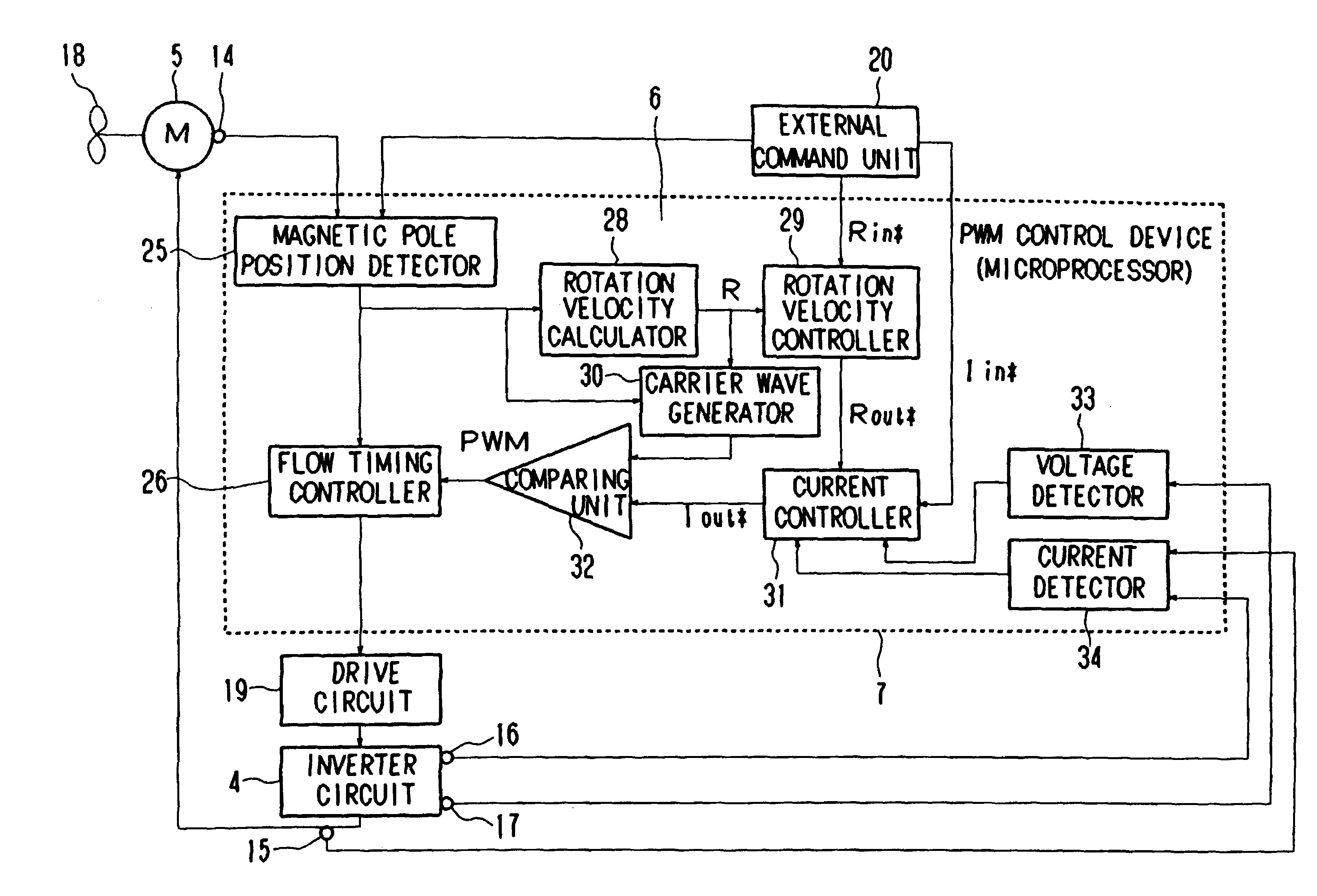

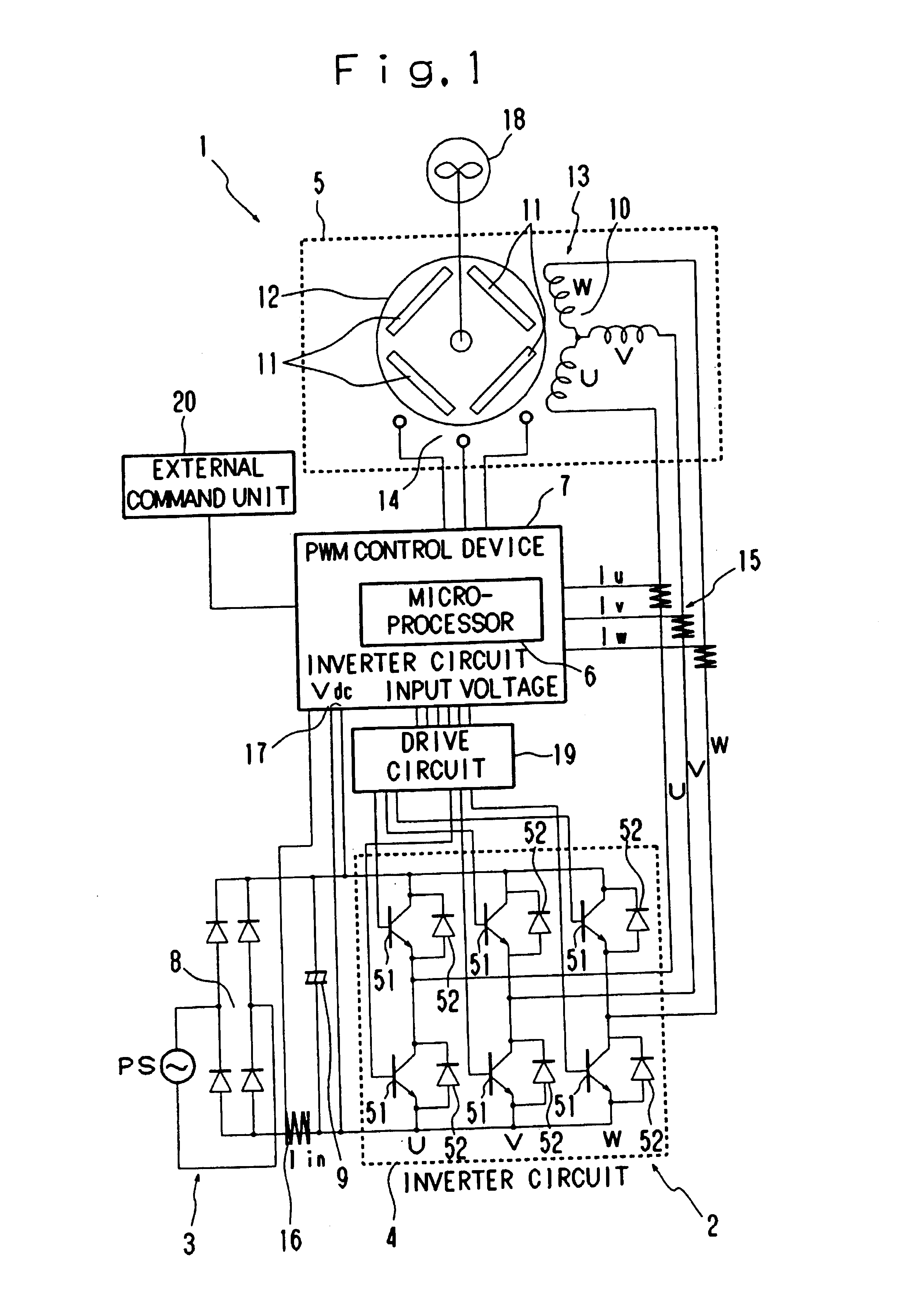

[0028]FIG. 1 is a circuit diagram showing a drive control circuit 2 of the motor-driven blower 1. The drive control circuit 2 is a device which rotatably drives a brushless motor 5 of the motor-driven blower 1 in response to a high-frequency current generated from an inverter circuit 4 high-frequency driven with a power source 3 as a drive source. The drive control circuit 2 drives and controls the inverter circuit 4 under a PWM control device 7 for performing PWM (Pulse Width Modulation) control using a microprocessor 6. The details of the respective parts or components of the drive control circuit 2 will be explained below.

[0029]The power source 3 converts an AC voltage generated from a commercial AC power supply PS to a DC voltage under rectifying / smoothing effects of a rectifier circuit 8 and a smoothing condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com