Pervaporation membranes and methods of use

a technology of pervaporation separation membrane and pervaporation chamber, which is applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of high operating cost, high capital cost of distillation process, high operating cost, etc., and achieve the effect of increasing the driving for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Poly(Acrylamide)-Grafted-Sodium Alginate Copolymer

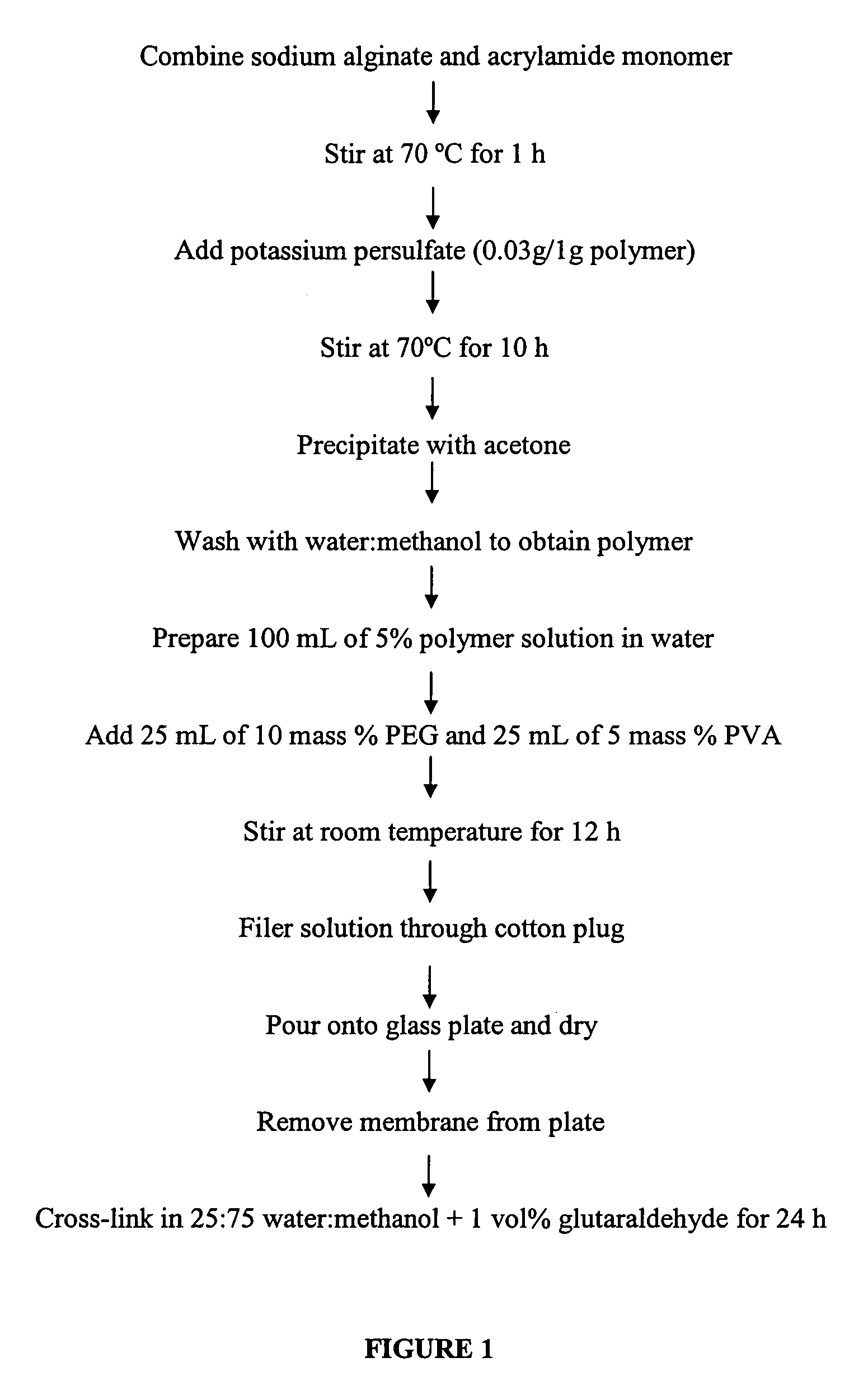

[0041]Sodium alginate, ammonium persulfate, isopropanol, acetone and methanol used in the following example were all of analytical reagent (AR) grade. Poly(acrylamide) grafted-sodium alginate copolymer was prepared by persulfate induced radical polymerization using sodium alginate polymer to acrylamide monomer ratios of 2:1 or 1:1. A 10 mass % aqueous solution of sodium alginate was prepared in a three-necked round bottom flask and stirred vigorously for 1 h after adding the correct ratio of acrylamide monomer at 70° C. Then, a 100 mL solution containing potassium persulfate initiator at a concentration of 10−3 moles (0.03 g / 1 g of expected polymer) was added and the reaction was continued for 10 h at 70° C. under nitrogen atmosphere. Free radical sites were generated by abstracting hydrogen from the —OH group of the polymer to facilitate the grafting of acrylamide onto sodium alginate. The mass obtained was precipitated...

example 2

Polymer Characterization of Poly(Acrylamide) Grafted-Sodium Alginate

[0046]Polymers prepared as described in Example 1 were characterized by Fourier transform infrared (FTIR) spectra of the polymer samples in KBr pellets using a Nicolet, Model Impact 410, USA in the wavelength region of 4000 to 400 cm−1. For the neat NaAlg, a characteristic broad band appearing at ˜3420 cm−1 corresponds to O—H stretching vibrations of NaAlg. A sharp peak observed at ˜1616 cm−1 corresponds to carbonyl group of —COONa moiety present in NaAlg. In the spectra of grafted copolymers, shoulder peaks appearing at ˜3190 cm−1 and a sharp peak at ˜1672 cm−1 corresponding to N—H stretching and C═O stretching vibrations, respectively and confirm the grafting reaction. A new peak at ˜1450 cm−1 in case of NaAlg-1 and NaAlg-2 corresponds to C—N bending vibration further providing evidence of the grafting reaction.

[0047]Viscosity measurements of the aqueous solutions of sodium alginate (NaAlg) and the grafted copolym...

example 3

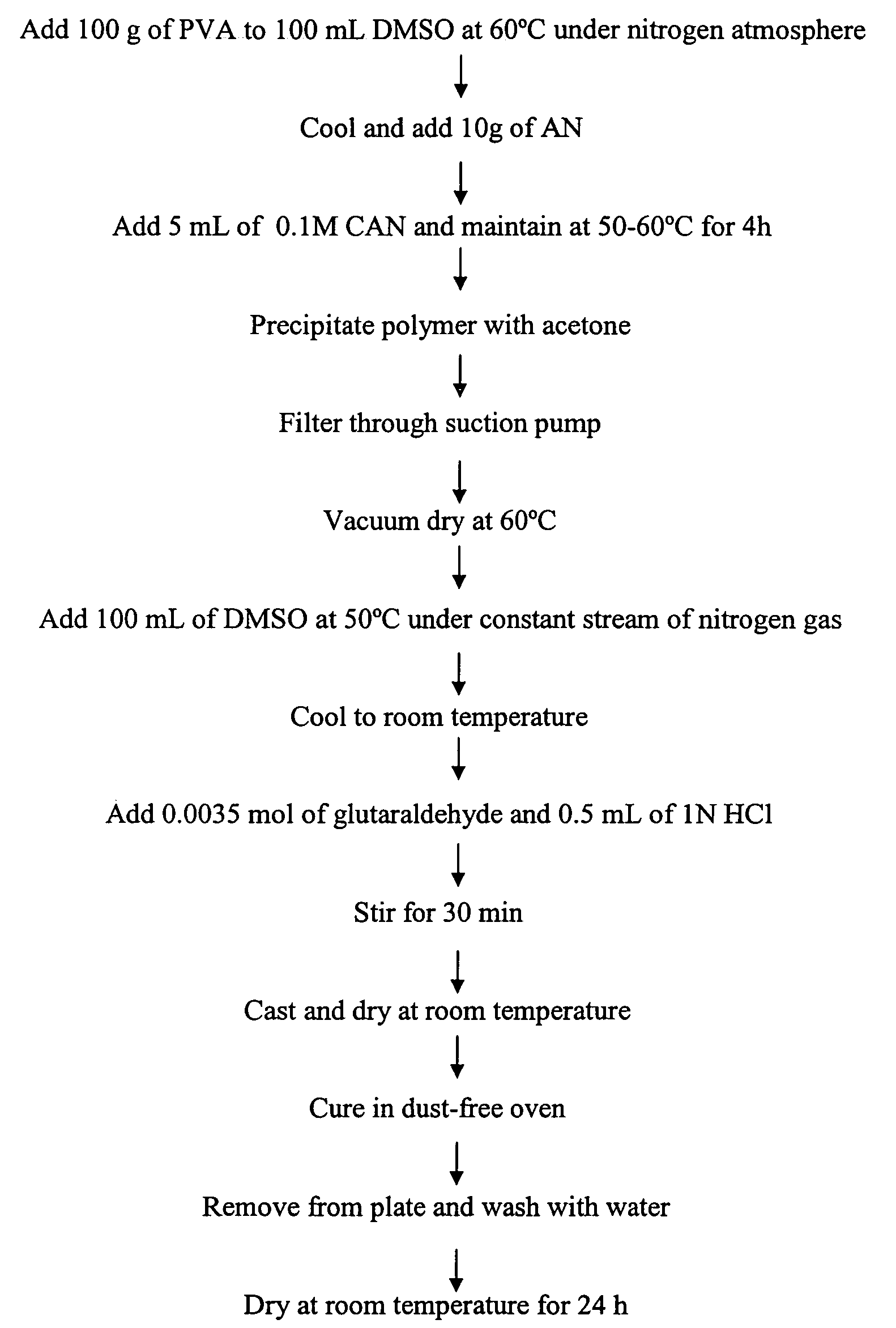

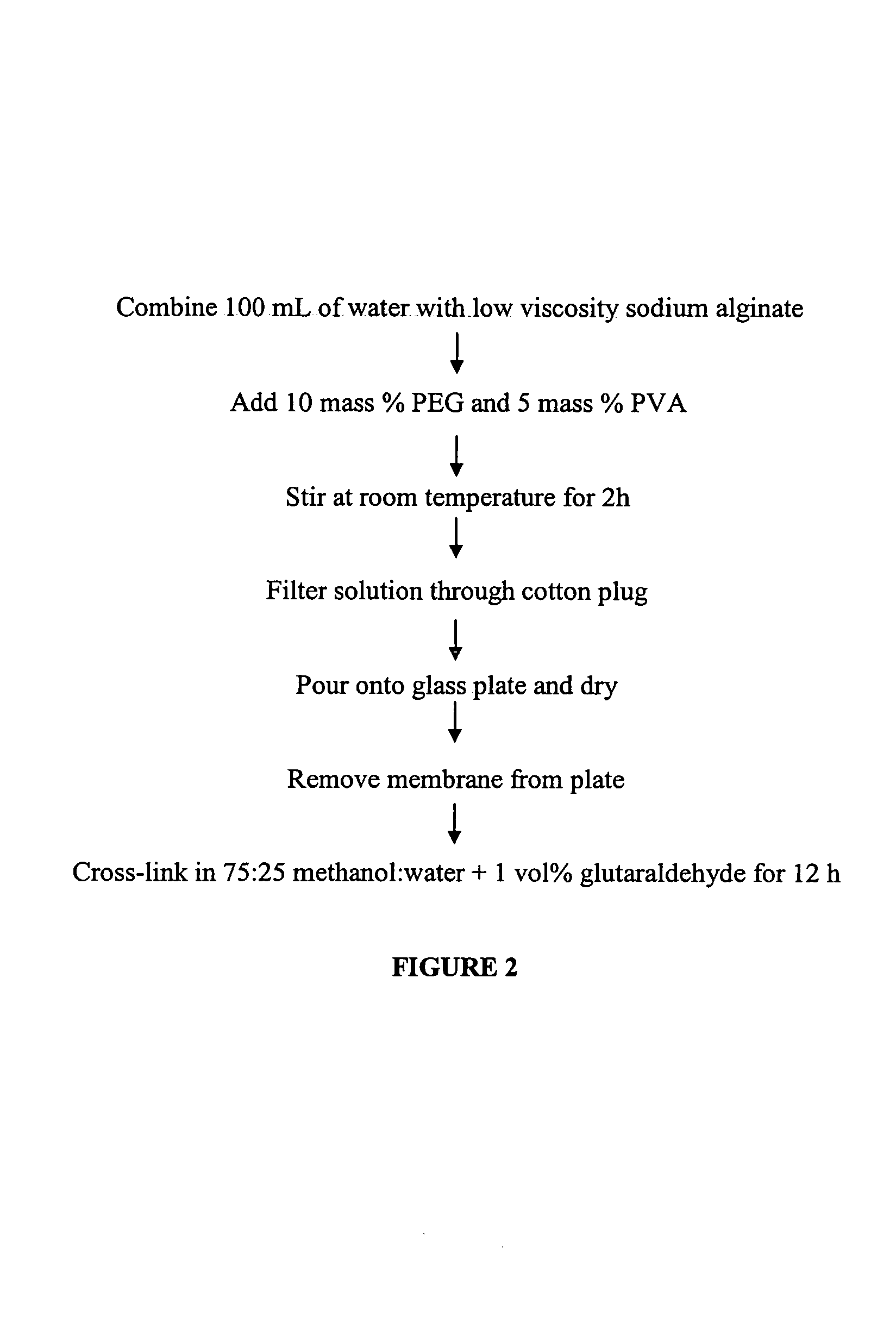

Fabrication of Poly(Acrylamide)-Grafted-Sodium Alginate Membranes

[0048]The following membranes were used in Examples 4–8. A 5% solution by mass of the poly(acrylamide)-grafted-sodium alginate copolymer (as described in Examples 1 and 2) was prepared in 100 mL distilled water. To this, 25 ml of a previously prepared solution of polyethylene glycol (PEG) sufficient to achieve 10 mass % PEG and 25 ml of a previously prepared solution of poly(vinyl alcohol)(PVA) sufficient to achieve 5 mass % PVA were added and stirred for 12 h at room temperature The solution was filtered through a cotton plug and membranes were cast on a leveled glass plate and dried at room temperature. The membranes obtained were peeled off from glass plate and cross-linked in acidic (25:75) water:methanol mixture containing 1.0 vol. % of glutaraldehyde for 24 h. The membranes were designated, respectively as NaAlg, NaAlg-1 and NaAlg-2 representing neat sodium alginate membrane, 2:1 alginate:acrylamide copolymer mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

| mass % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com