Setting tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

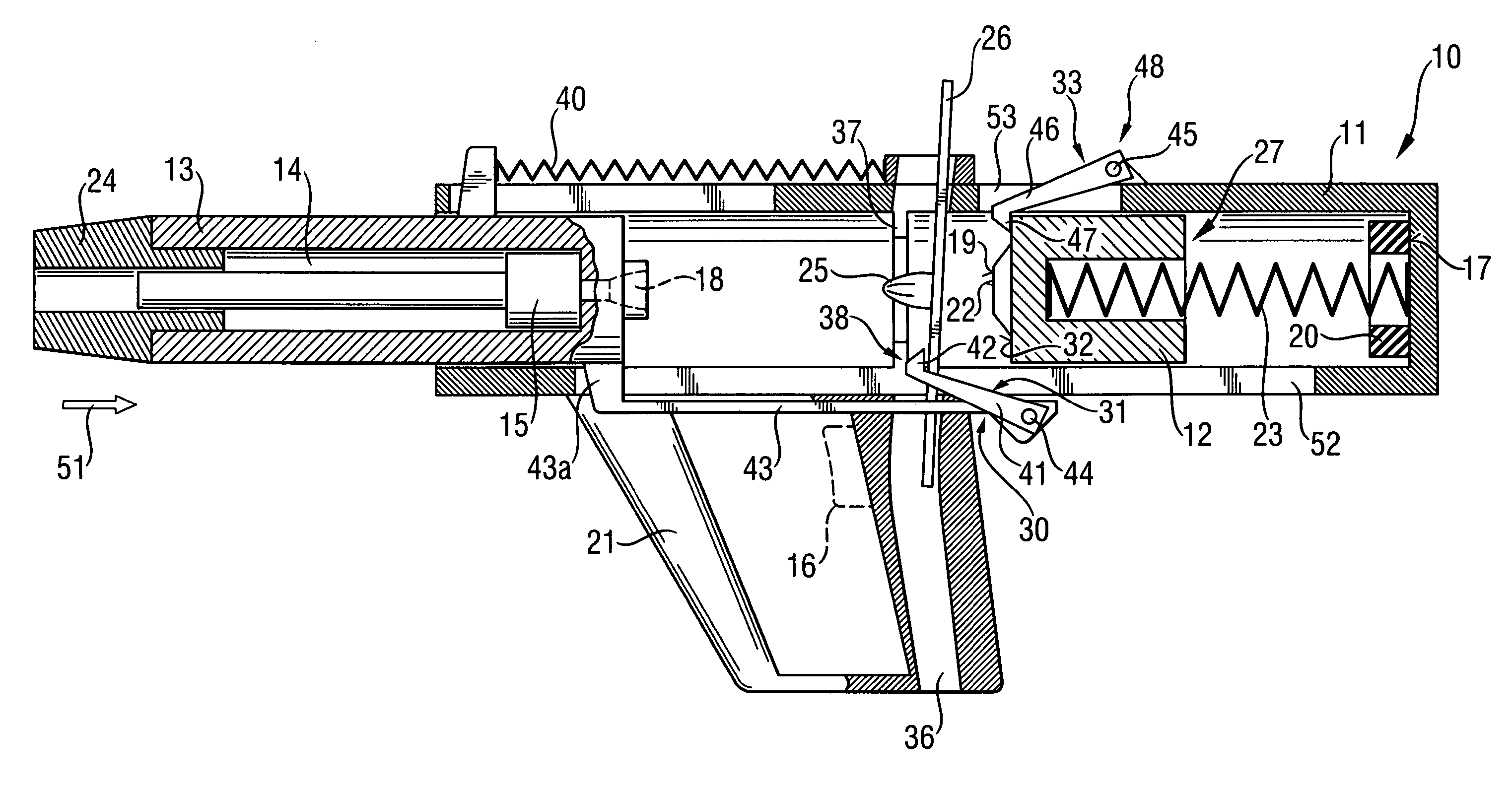

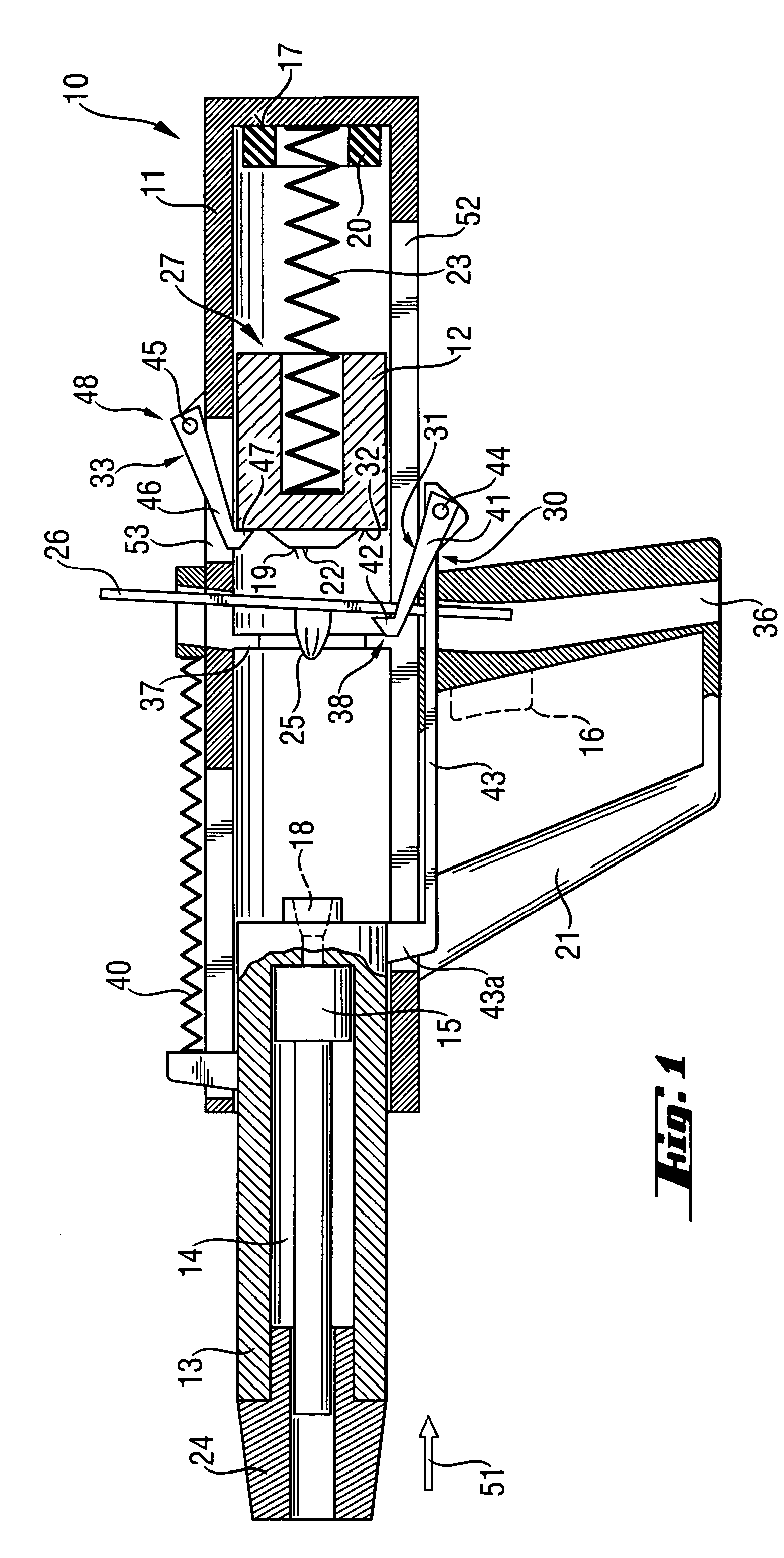

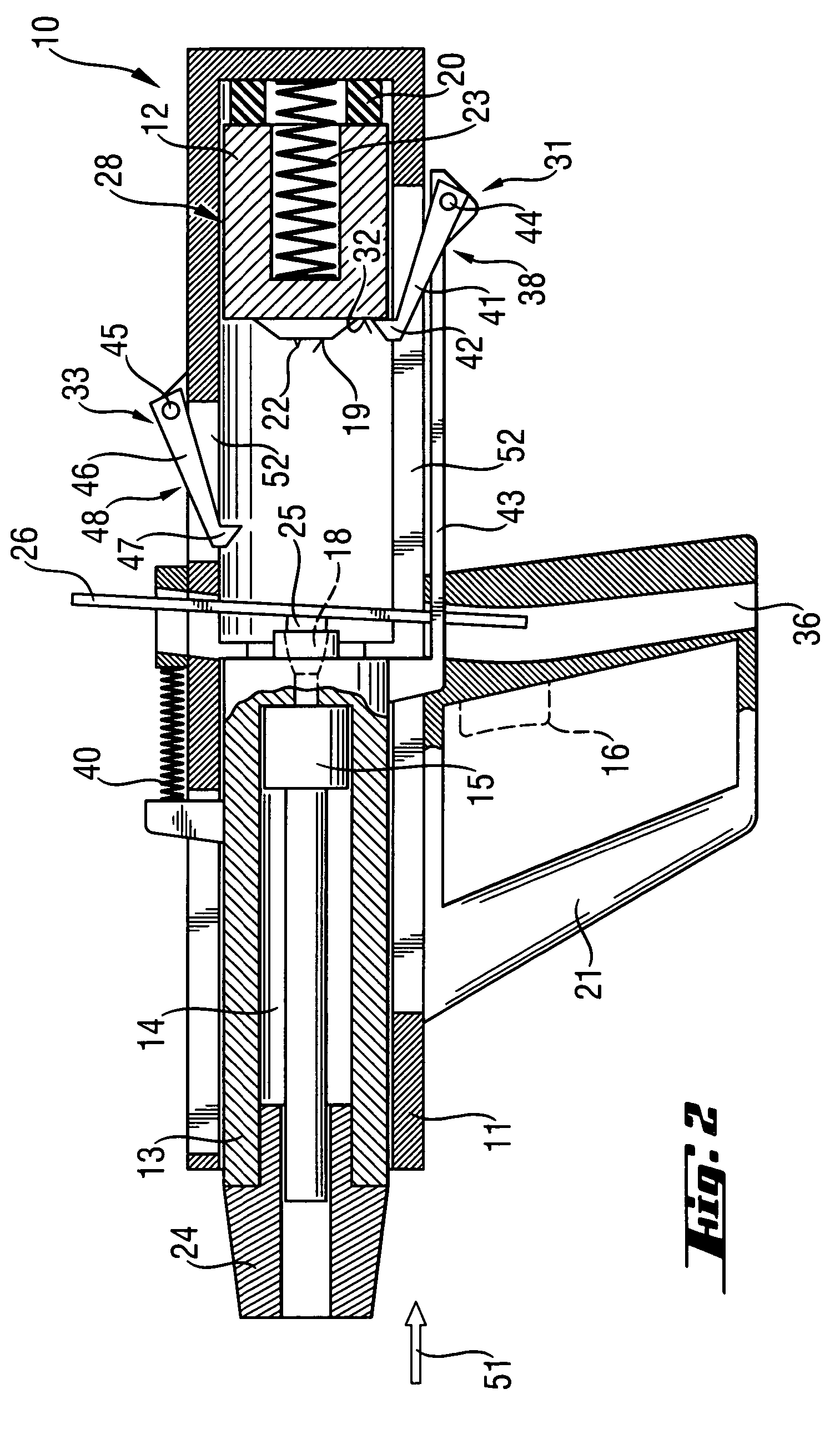

[0031]A setting tool 10 according to the invention and which is shown in its inoperative position in FIG. 1, includes a one- or multi-part housing 11 and a piston guide 13 supported in the housing 11. A piston 15 is displaceably supported in a hollow chamber 14 of the piston guide 13. The piston 15 is driven by propellant 25 or its expending combustion gases. In the embodiment shown in FIGS. 1–5, a handle 21 is secured on the housing 11. The handle 21 carries an actuation switch 16 for initiating a setting process by a user of the setting tool 10. The handle 21, which is shown in FIGS. 1–5, is not shown in FIGS. 6–10, though the setting tool shown in FIGS. 6–10 can also be provided with a similar handle. It should be understood that the setting tool 10, in addition to the housing 11, can have further housing components or an outer protection housing formed, e.g, of a plastic material.

[0032]The piston guide 13 is displaceable arranged in a sleeve-shaped housing 11 and is supported ag...

second embodiment

[0046]FIG. 6 shows the setting tool 10 in its inoperative position in which the setting tool 10 is ready to be ignited, with the ignition unit 12 located in its pre-loaded position 28 against the energy accumulator 23. The ignition unit 12 is held in this position by the locking pawl 41. The piston guide 13 projects out of the housing 11, and the catch pawl 46 projects into the interior of the housing 11 for catching the ignition unit 12 in case it is displaced, for some reason, forward, without the actuation of the setting tool 10.

[0047]FIG. 7 shows a position in which the setting tool 10 is pressed against a constructional component. The piston guide 13 is displaced into the housing 11. The catch pawl 46 is pivoted out of the interior of the housing 11 by the crank means 54. However, the locking pawl 41 still engages the ignition unit 12, retaining it in its pre-loaded position 28.

[0048]FIG. 8 shows a position in which the actuation switch (discussed with reference to FIG. 1) has...

third embodiment

[0053]FIG. 9 shows the setting tool 10 according to the present invention in its inoperative position. The ignition unit 12 is held by the catch pawl 46, which is located in its locking position 48, in its intermediate position 27. When the setting tool 10 is pressed against a constructional component, the servo-component 43 and the locking pawl 41, which is carried thereby, are displaced together with the bolt guide in the direction 51. The guide unit 12 is catched by the locking pawl 41 and is displaced thereby rearwardly until it impacts the damping element 20. The ignition unit 12 is in its pre-loaded position (not shown). As in the embodiment shown in FIGS. 1–5, upon actuation of the actuation switch (such as the switch 16 carried by the handle 21 in FIG. 1), both pawls 41, 46 pivot to their respective release positions (not shown).

[0054]FIG. 10 shows a position in which the setting tool 10 is actuated, and the ignition unit 12, together with the ignition peg 22 and the cartrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com