LSI package

a technology of large-scale integration and packaging, applied in the direction of printed circuits, semiconductor devices, semiconductor/solid-state device details, etc., can solve the problems of not being supplied with a sufficiently high voltage at the power supply terminal of the lsi chip, too large voltage drop in the single-source voltage supply terminal to be ignored, etc., to reduce unnecessary electromagnetic radiation from the lsi package, reduce noise from outside, and suppress unnecessary electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

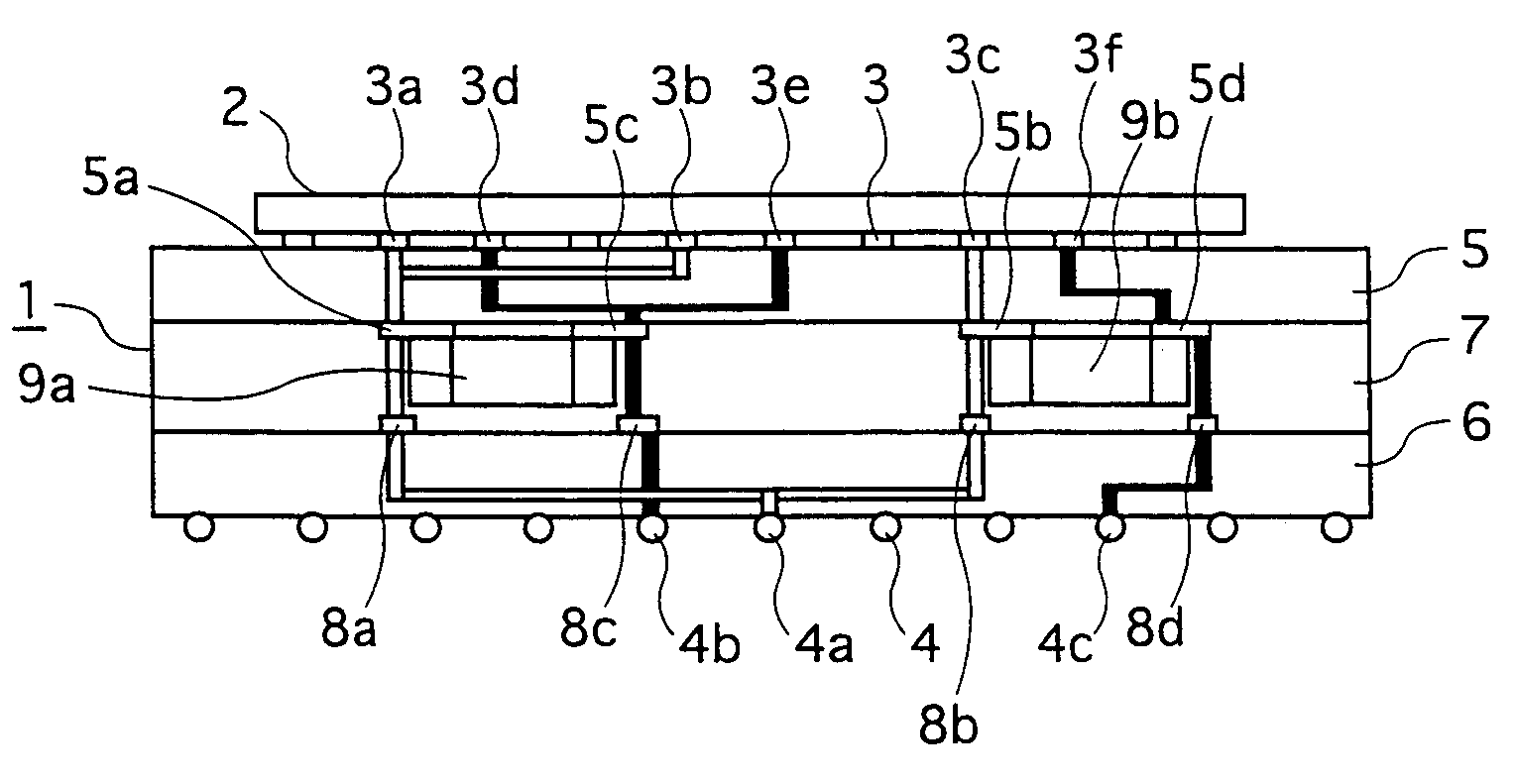

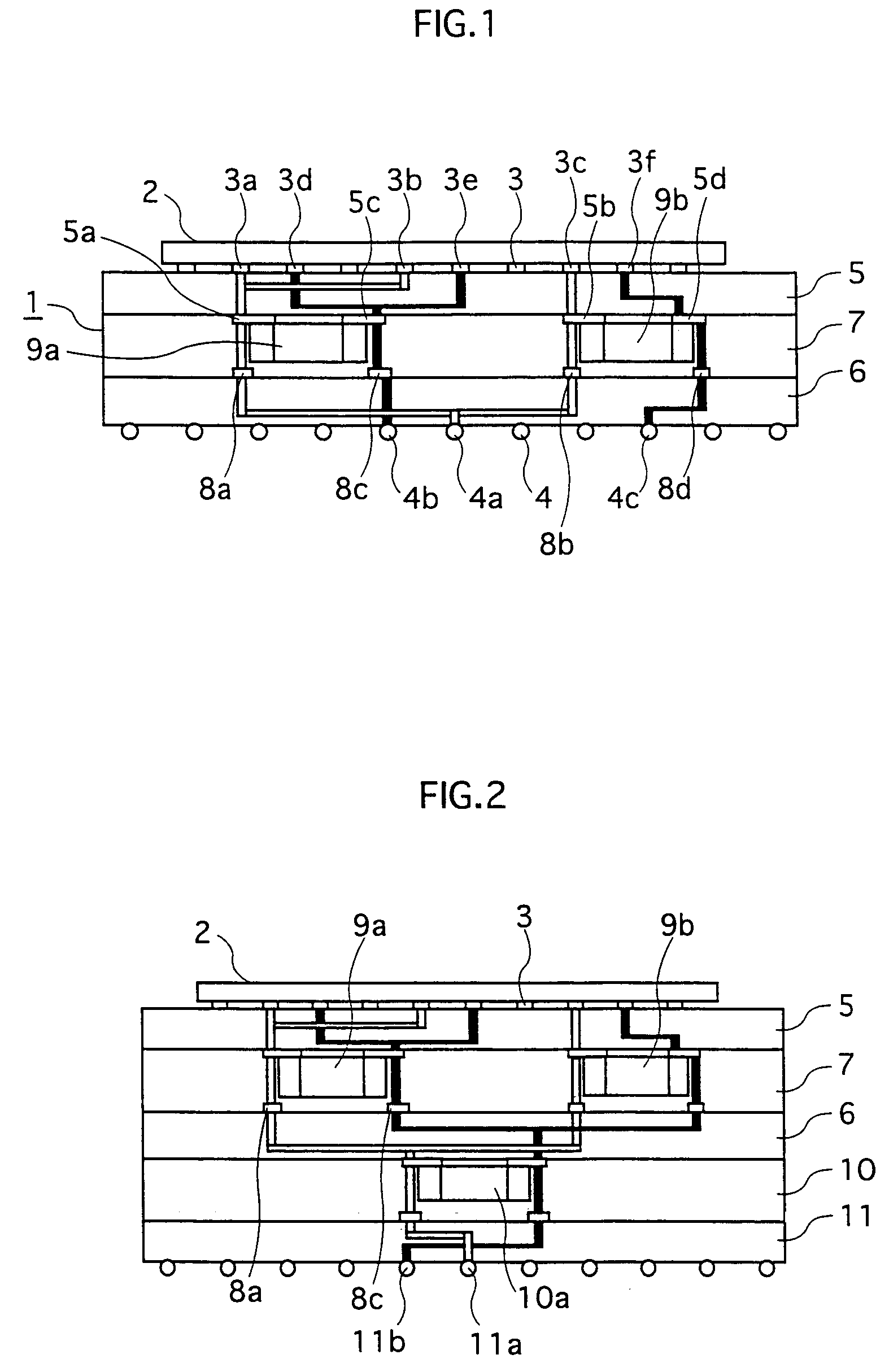

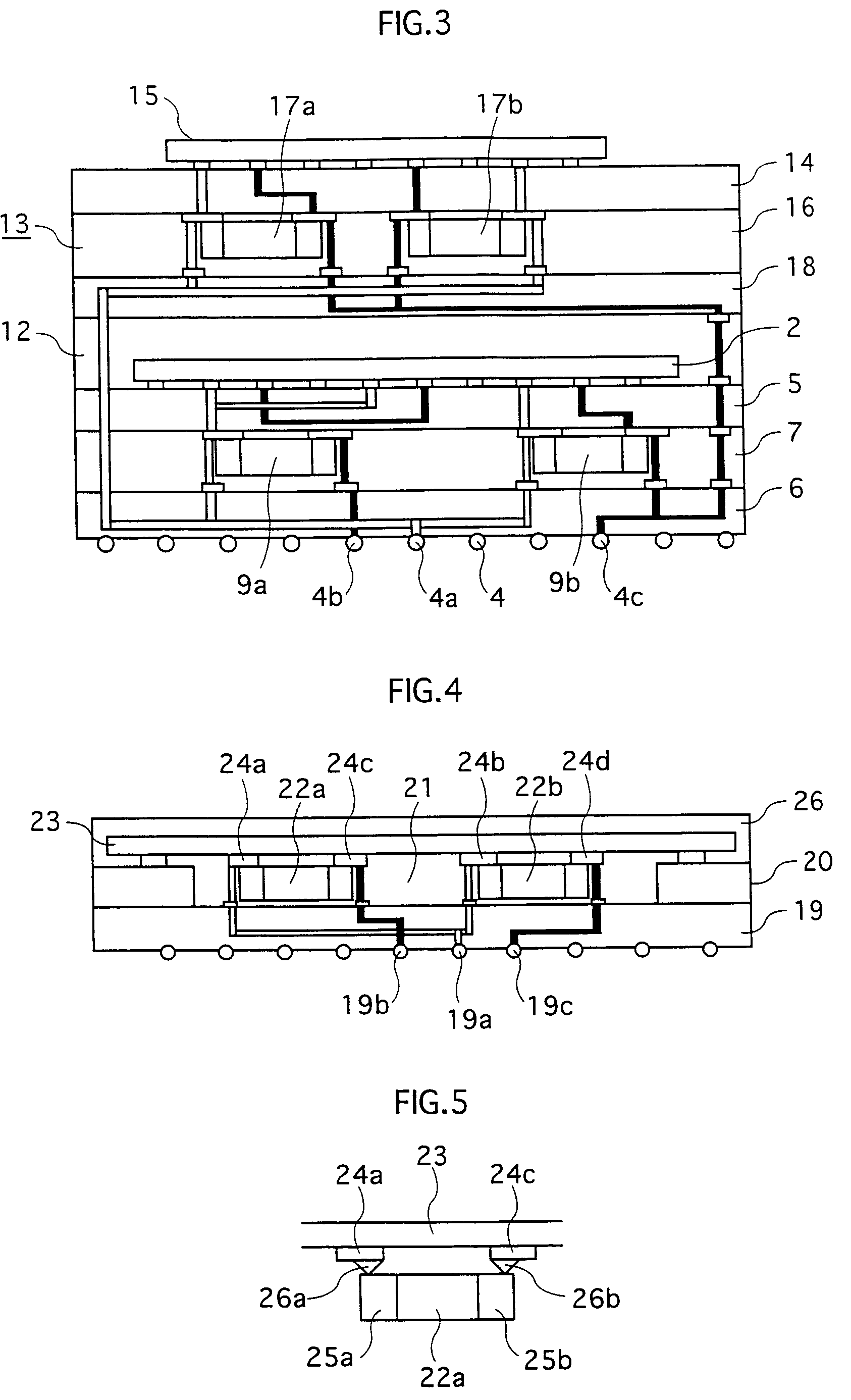

[0042]The following part describes LSI packages relating to embodiments of the present invention with reference to the attached figures. The attached figures show the cross sections of the LSI packages, and do not include hatchings for better understanding of the construction.

[0043]As shown in FIG. 1, an LSI package is constituted by a substrate 1 forming the main body of the LSI package and an LSI chip 2. A plurality of bumps are arranged in a grid pattern, as terminals 3, on the LSI chip 2. A plurality of solder balls are arranged in a grid pattern, as terminals 4, on one surface of the substrate 1. The terminals 3 and 4 include signal input / output terminals, power supply terminals, and earth terminals. Signal input / output terminals are not directly related to the present invention, and therefore not explained here.

[0044]The substrate 1 has a three-layer construction, which includes a multilayer circuit board 6 on which the terminals 4 are provided, a multilayer circuit board 5 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com