Humidity control system for combination oven

a technology of humidity control and combination oven, which is applied in the direction of domestic stoves or ranges, furnaces, milk treatment, etc., can solve the problems of adversely affecting the efficiency of the oven, affecting the cooking time and texture of food cooked, etc., and achieves the effect of improving thermal efficiency and increasing the surface area of impinging water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

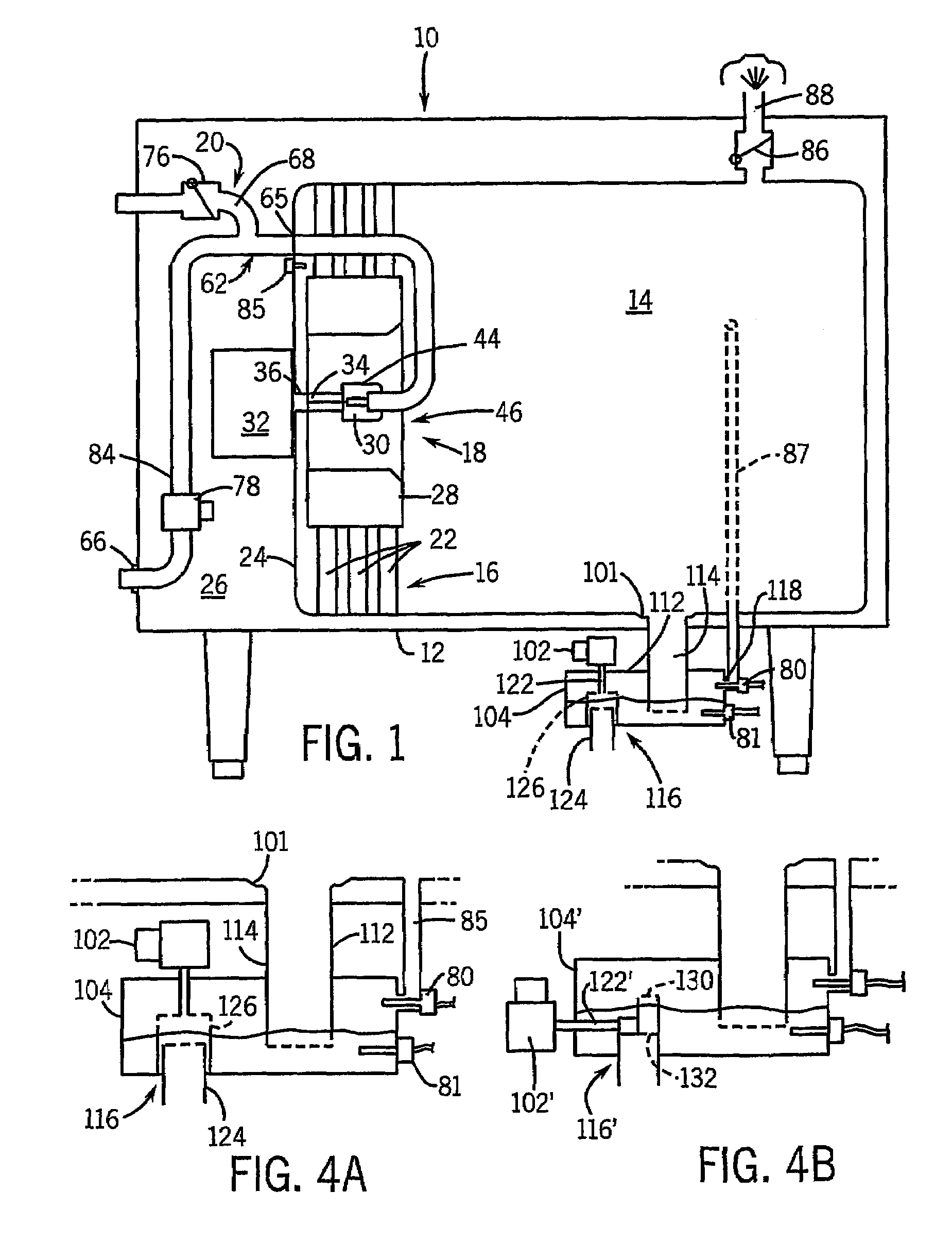

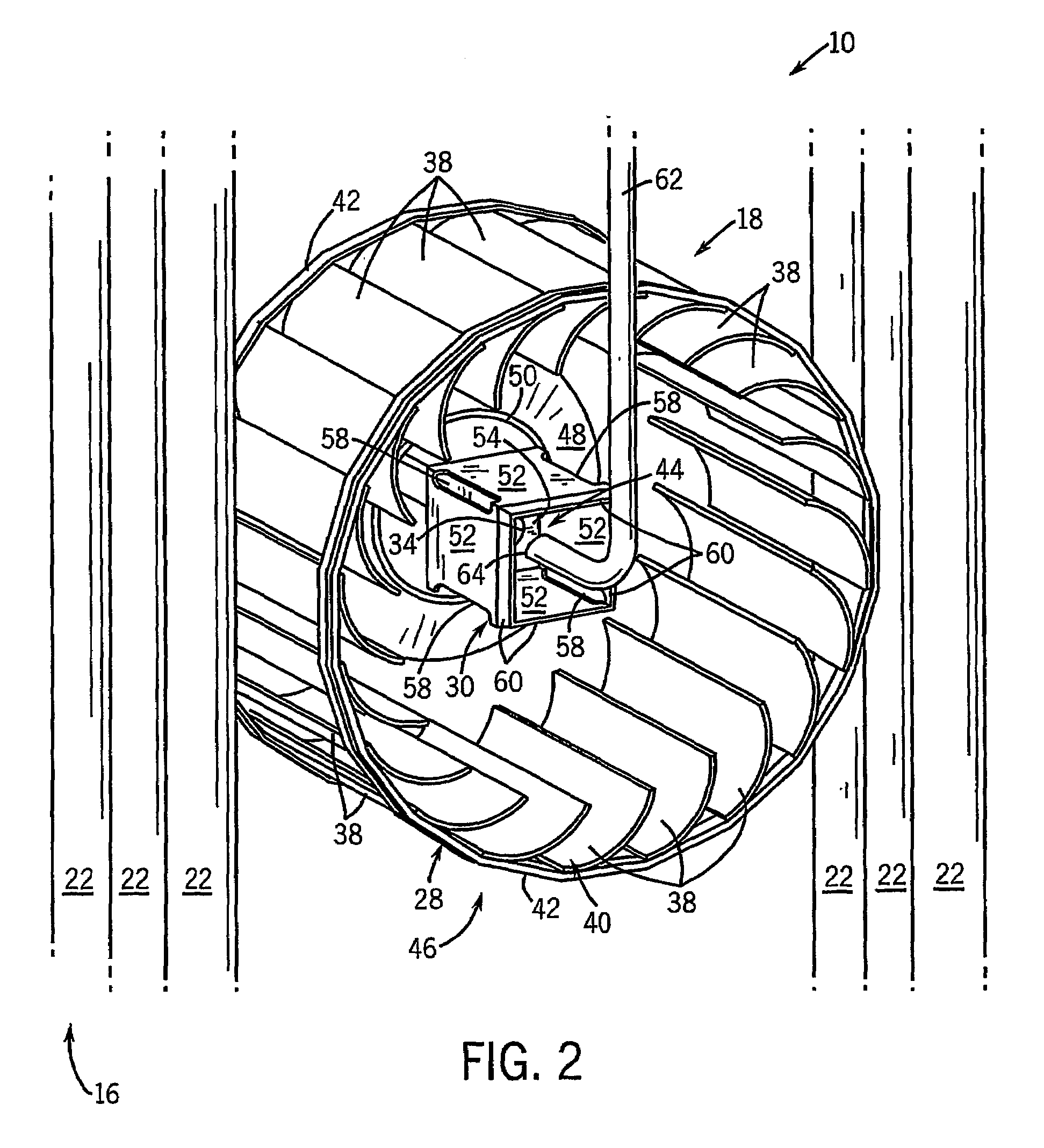

[0029]Referring to FIGS. 1–3, a combination convection and steam cooking oven 10, includes an oven enclosure 12 defining a cooking chamber 14 for heating foodstuffs. The oven 10 also includes a heating system 16, an atomizer assembly 18 and a humidity control system 20. The heating system 16 generally includes burners 21 which heat gas circulated through heating elements 22 preferably consisting of metallic conduits. Preferably, the heating elements 22 include two sets of three conduits extending vertically in close proximity to a partition wall 24 of the oven enclosure 12 separating the cooking chamber 14 from an electronics compartment 26. It should be noted that the heating elements 22 could also be suitable solid resistive heating elements.

[0030]Referring to FIGS. 1 and 2, the atomizer assembly 18 includes a motor-operated fan 28 and an atomizer cup 30 both of which are disposed between the heating elements 22, three of the heating elements 22 being on each side of the atomizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com