Iron-based sintered alloy material and production method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

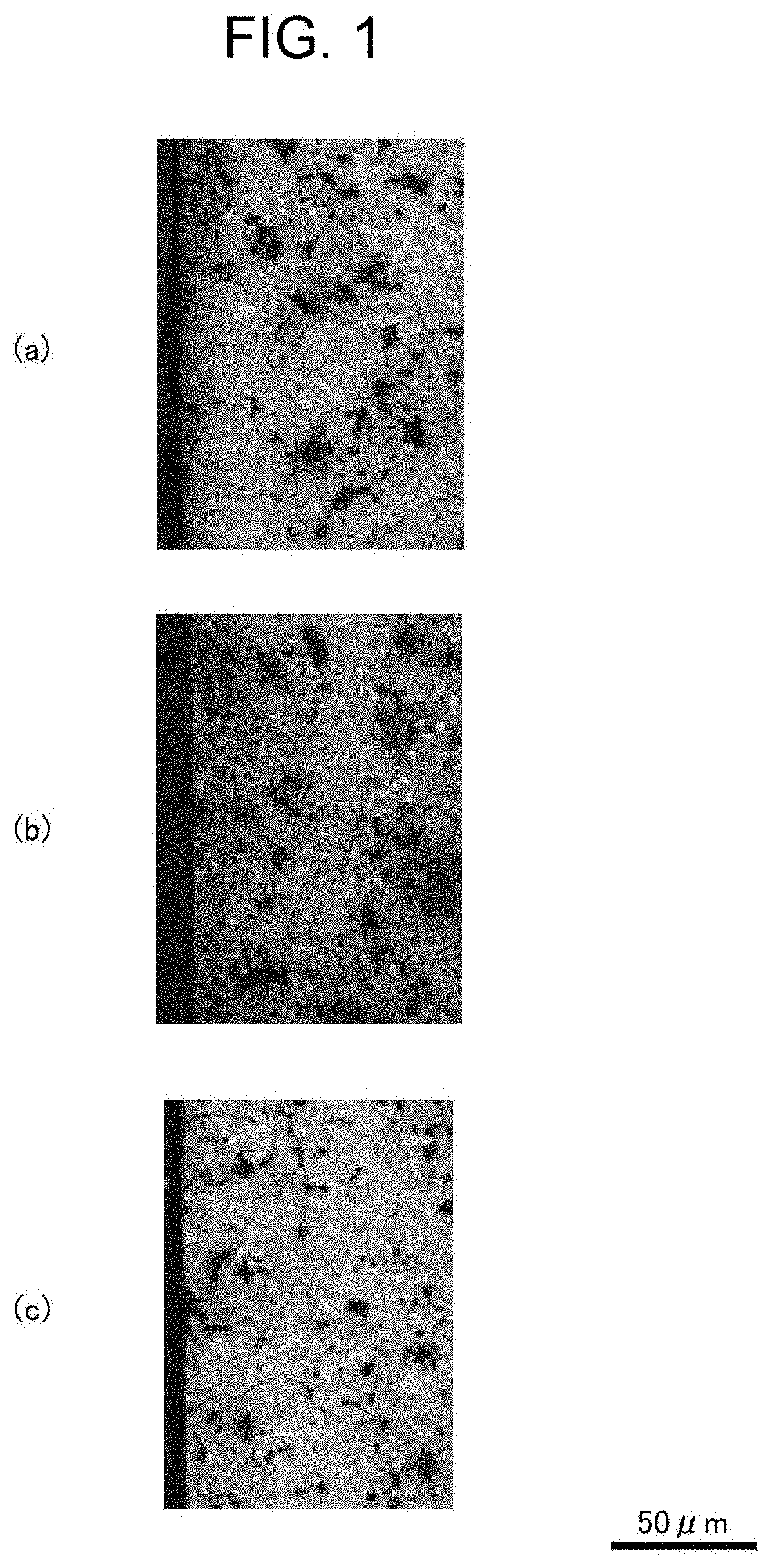

Image

Examples

example 1

[0048](Sample 1)

[0049]A graphite powder was blended with an Fe—Cr—Mo—Mn alloy powder and mixed uniformly to prepare a raw material powder having an overall composition (% by mass) containing 0.5% of Cr, 0.2% of Mo, 0.2% of Mn, 0.5% of C, and the remainder as Fe. Using this raw material powder, molding and sintering were conducted in the manner described below.

[0050]A mold having a ring-shaped cavity with an outer diameter of 50 mm, an inner diameter of 30 mm and a length of 6 mm was prepared, and the raw material powder was placed in the cavity and compressed using a punch, thus forming a green compact with a green density of about 7.2 Mg / m3. This green compact was installed in a sintering furnace and heated at 1,200° C. in a mixed gas atmosphere containing 90% nitrogen and 10% hydrogen, and following sintering for 60 minutes, the temperature inside the furnace was lowered, obtaining an iron-based sintered alloy substrate of sample 1. The density was measured by the Archimedes princ...

example 2

[0067]A mold having a cavity for molding a sprocket for a variable phase system with an over-pin diameter of 94.425 mm was prepared. An Fe—Mo—Ni alloy powder, a graphite powder and a molding lubricant were blended to prepare a mixed powder having an overall composition (% by mass) containing 0.55% of Mo, 0.55% of Ni, 0.25% of C, and the remainder as iron and unavoidable impurities, and using this mixed powder as a raw material powder, the same operations as Example 1 were conducted to produce an iron-based sintered alloy substrate having a sprocket shape. Subsequently, the teeth of the sprocket were subjected to a rolling treatment to densify the outermost surfaces of the teeth.

[0068]Using the above substrate, nitroquenching or carburizing quenching was performed in the same manner as Example 1, thus obtaining a sprocket-shaped iron-based sintered alloy material having a hardened layer formed at the surface. However, the nitriding temperature was set to 700° C. and the carburizing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com