Precast concrete wall with elevated roadway and method for constructing wall

a technology of precast concrete and elevated roadways, which is applied in the direction of walls, ways, constructions, etc., to achieve the effect of efficiently moving modules and efficiently shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

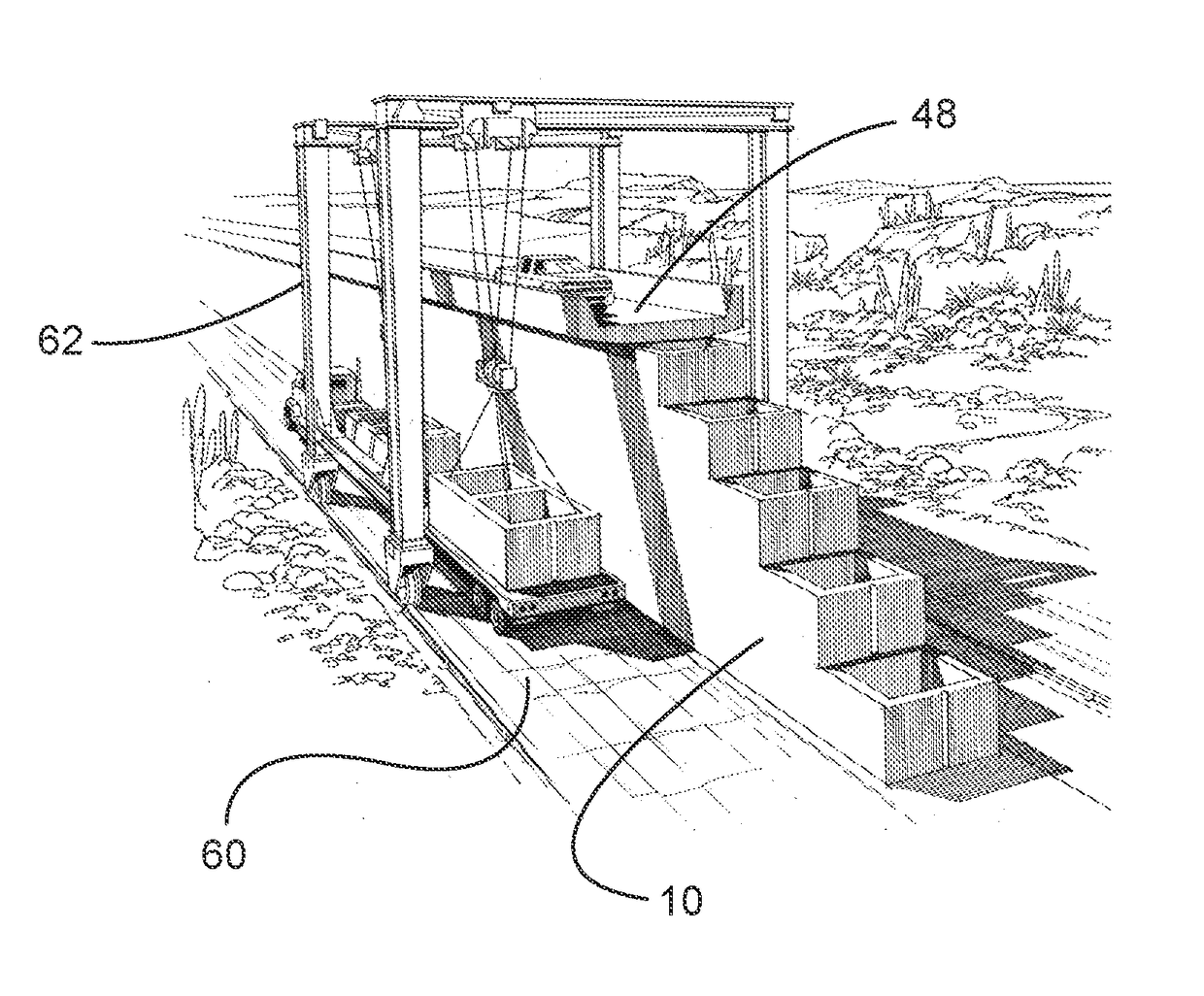

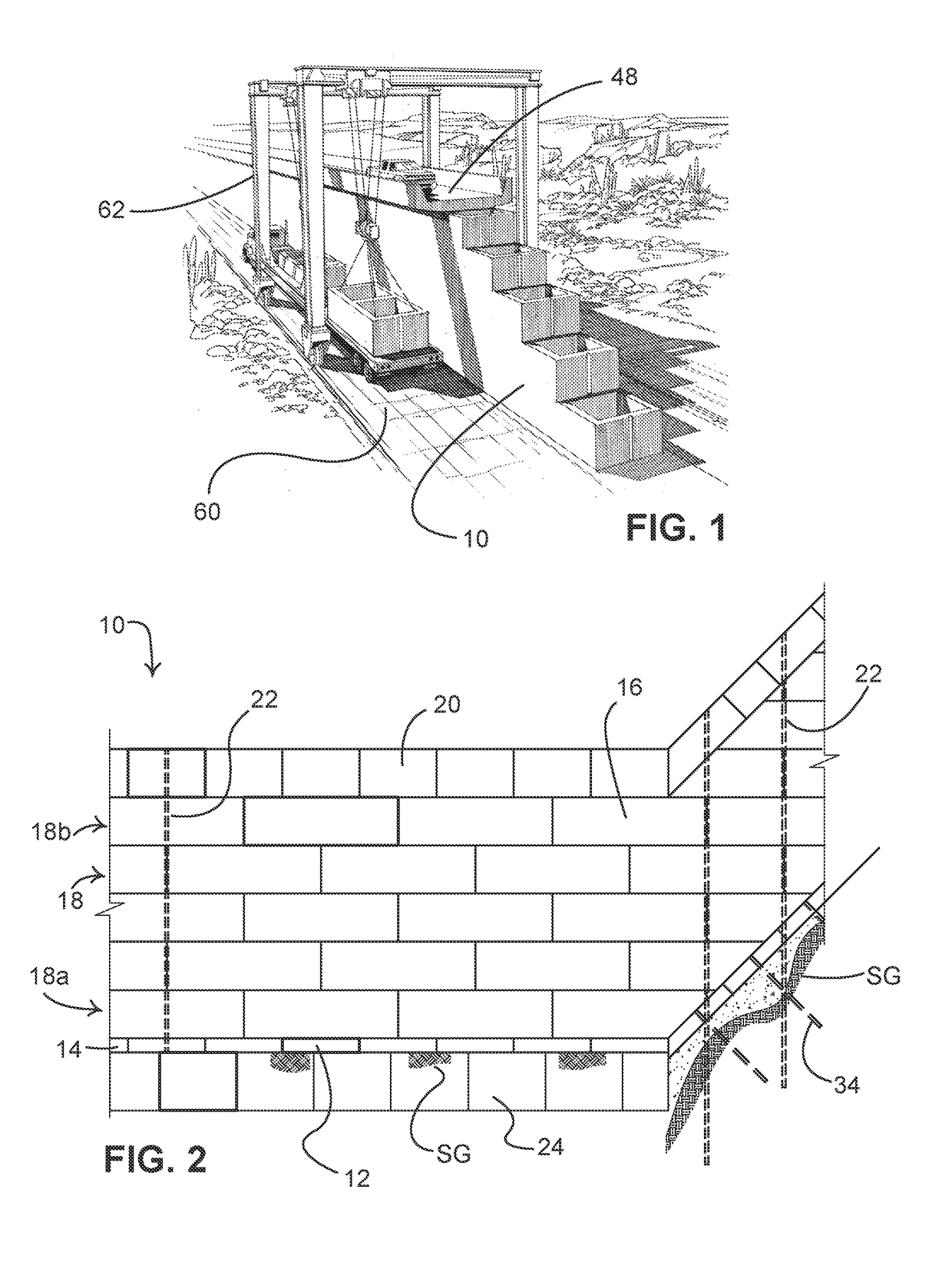

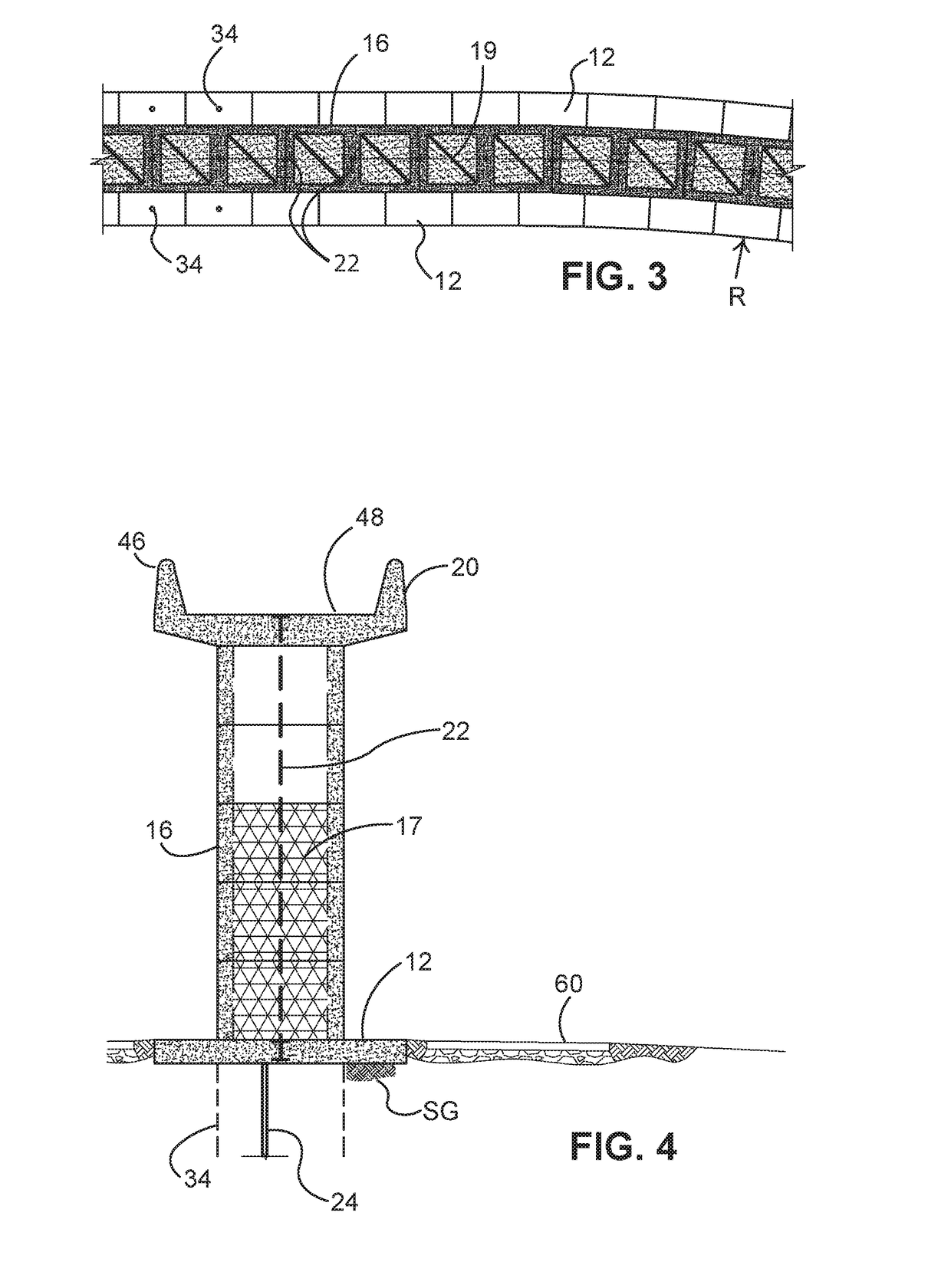

[0022]Turning now to the drawings, a precast concrete wall 10 is constructed on a prepared subgrade SG, as shown in FIGS. 1-4. The wall 10 comprises a plurality of precast, steel-reinforced concrete foundation modules 12, arranged end to end in a foundation course 14; a plurality of precast, steel-reinforced concrete wall modules 16 arranged in two or more courses 18; a plurality of precast, steel-reinforced cap modules 20 arranged end to end on the top of the wall modules; and a plurality of tie down rods 22. The tie down rods extend through the cap modules 20, two or more wall modules 16, and at least partially into the foundation modules 12. In one embodiment, the tie down rod comprises a 1-inch diameter (#8) grade 60 rebar with threaded ends.

[0023]To deter tunneling under the wall, an optional but preferred barrier 24 is inserted in the subgrade before the foundation modules 12 are placed. In relatively flat terrain a trenching wheel with cutting teeth can be used to cut a narro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com