Flat Lamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

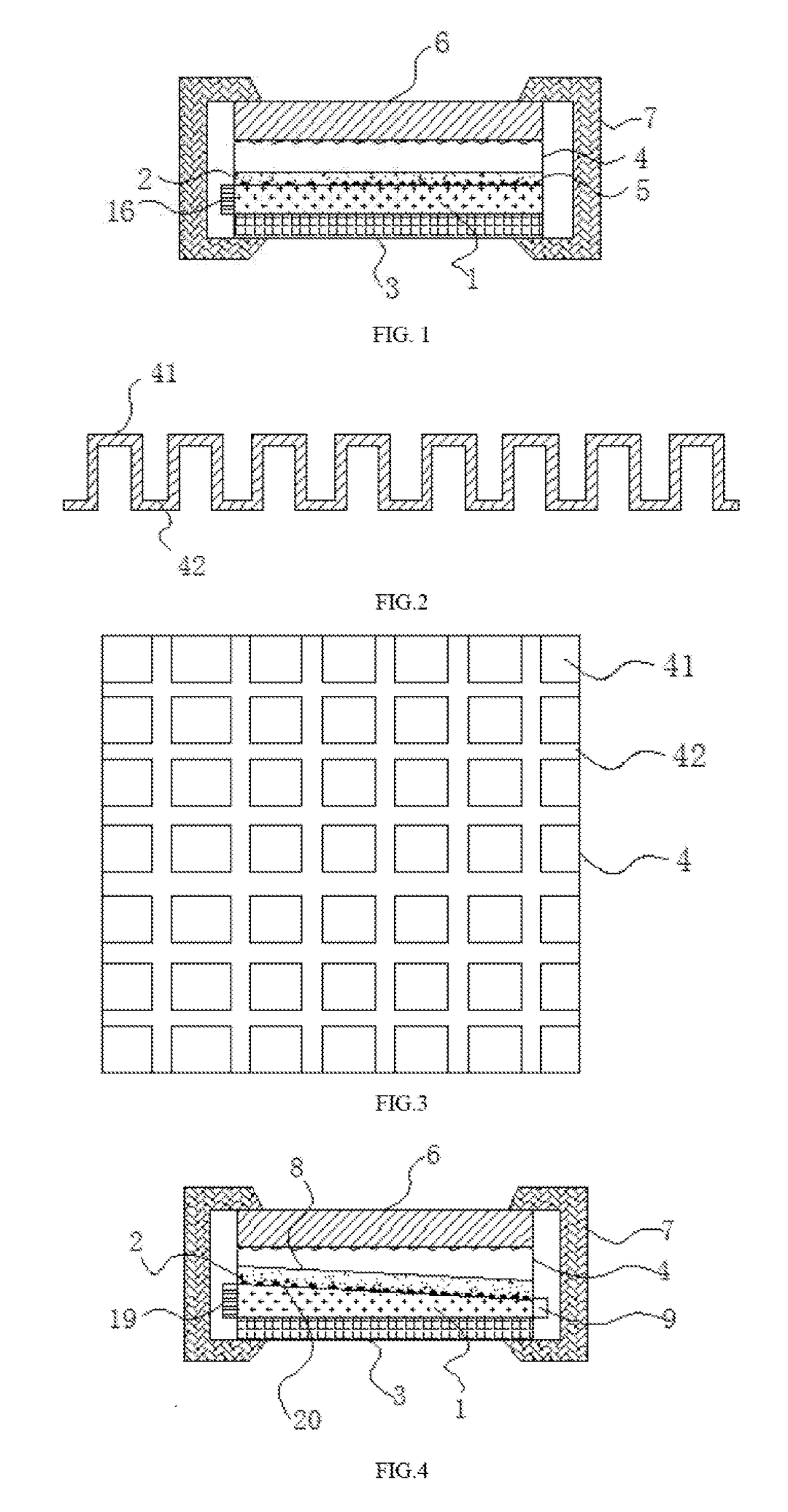

[0156]A flat lamp as shown in FIG. 4, the light guide layer 1 is wedge-shaped with a right-angled trapezoidal cross-section; the thick side of the light guide layer 1 is the light incident side provided with LED light bars 19, and the thin side of the light guide layer is provided with buffer materials 9,wherein the cross section of the buffer layer 4 or the backplane 6 is also a right-angle trapezoid, and the stacked structure composed of the backplane 6, the light guide layer 1, the reflective layer 2 he buffer layer 4 and the diffusion layer 3 is in the shape of a flat plate.

embodiment 2

[0157]A flat lamp, the stacked structure composed of the backplane 6, the light guide layer 1, the reflection layer 2, the buffer layer 4 and the diffusion layer 3 is in the shape of a flat plate structure which is one of the following three:

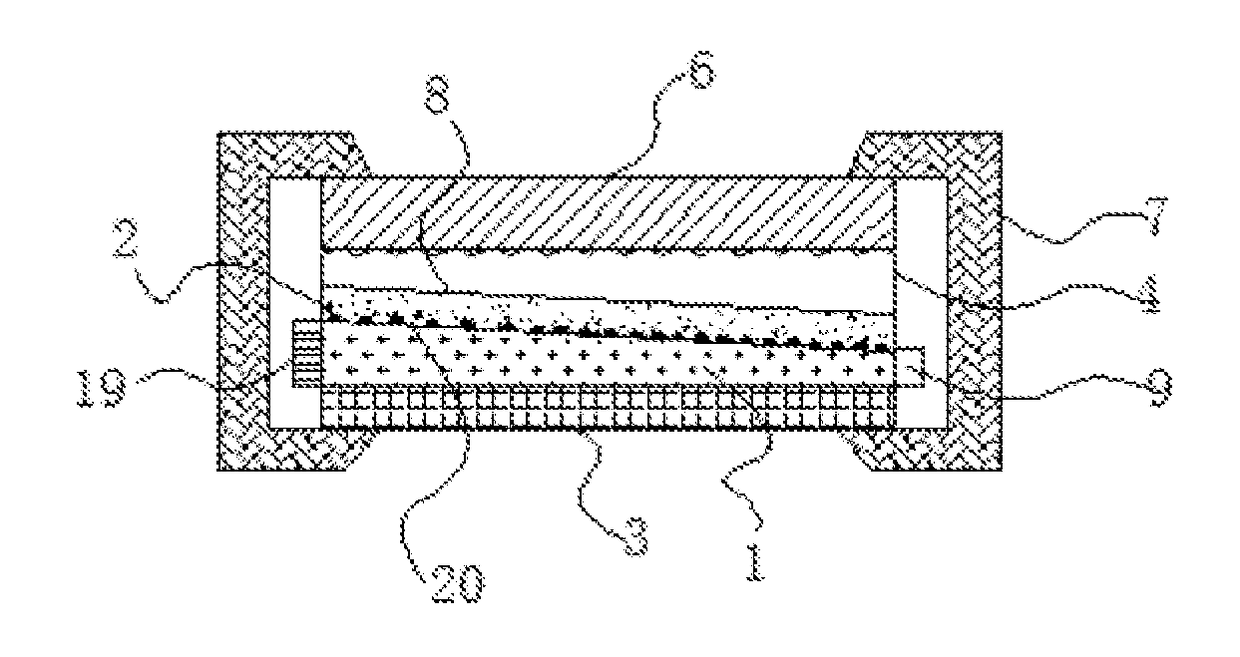

[0158](1) The light guide layer 1, the buffer layer 4, the reflective layer 2 and the backplane 6 are all in the shape of a flat plate, as shown in FIG. 1;

[0159](2) The light guide layer 1 is a wedge-shaped light guide layer with a right-angled trapezoidal cross-section, the buffer layer 4 is a wedge-shaped buffer layer with a right-angled trapezoidal cross-section, and the back face of the light guide layer 1 is a first inclined plane 20, the side of the buffer layer 4 close to the reflection layer 2 is a second inclined plane 8, the first inclined plane 20 is parallel to the second inclined plane 8, the reflection layer 2 is positioned between the first inclined plane 20 and the second inclined plane 8, and the backplane 6 and the reflection l...

embodiment 3

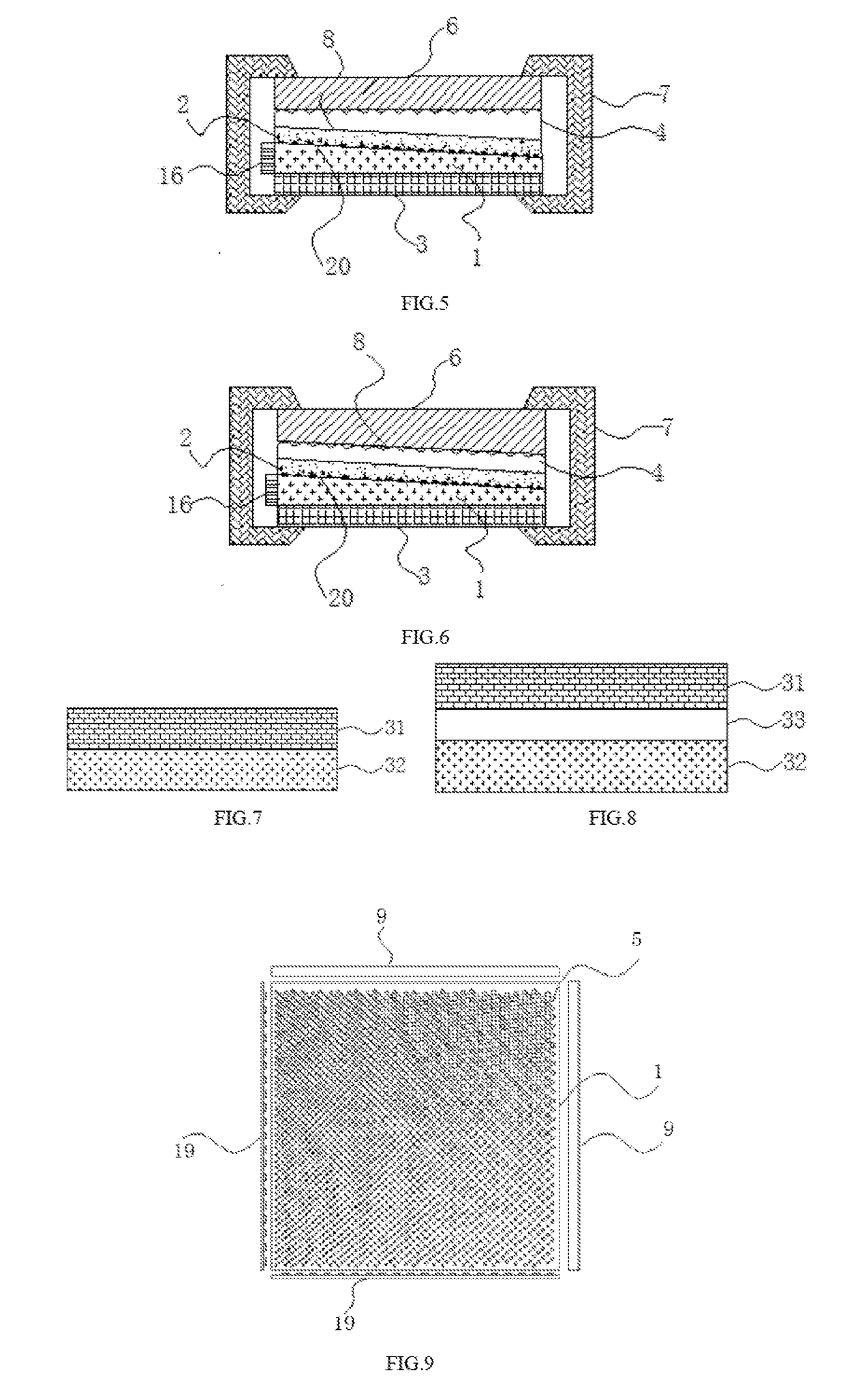

[0162]As shown in FIGS. 7 and 8,the embodiment 3 has a similar structure to that of embodiment 1, except that: the diffusion layer 3 includes a first diffusion monolayer 31 and a second diffusion monolayer 32; the first diffusion monolayer 31 has opposite two faces including a light incident face and a first superimposed face of the diffusion layer 3; the second diffusion monolayer 32 has opposite two faces including a light-emitting face and a second superimposed face of the diffusion layer 3; the first superimposed face of the first diffusion monolayer 31 and the second superimposed face of the second diffusion monolayer 32 are superimposed on each other; the incident face of the first diffusion monolayer 31 and the light-emitting face of the light guide layer 1 are in contact with each other, and the hardness of the first diffusion monolayer 31 is smaller than that of the second diffusion monolayer 32.

[0163]The structure of the diffusion layer is one of the following three:

[0164]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com