Polymeric concrete for wind generator towers or other large structural applicatons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

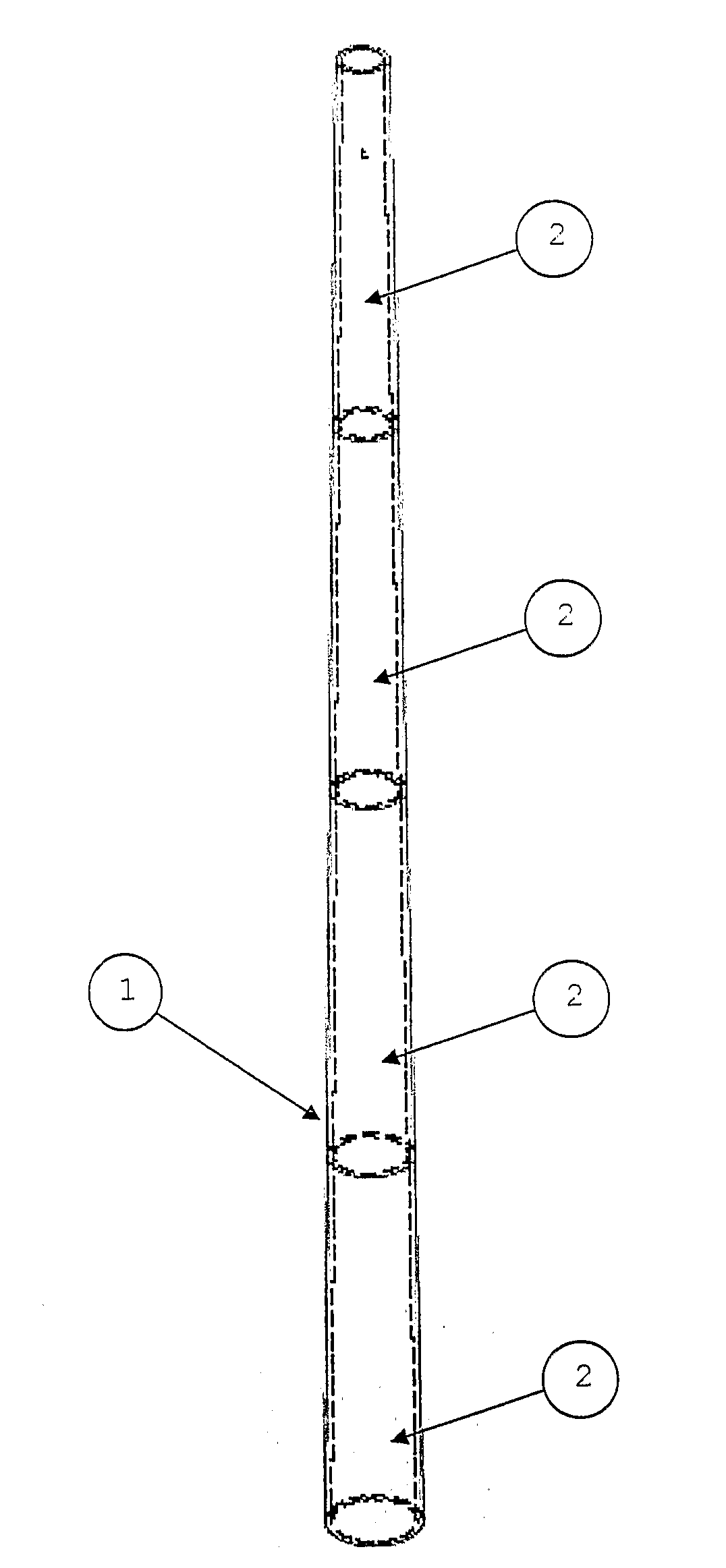

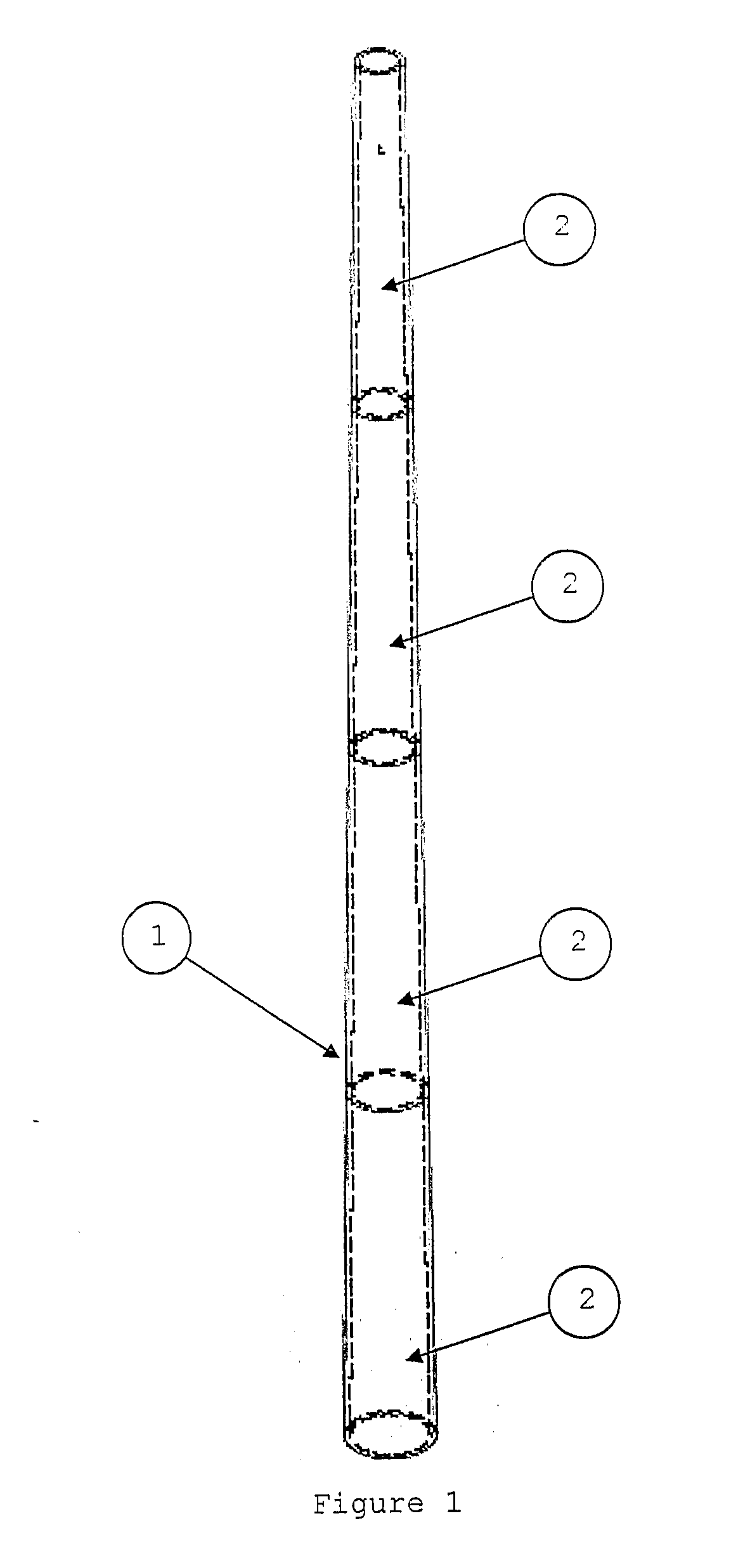

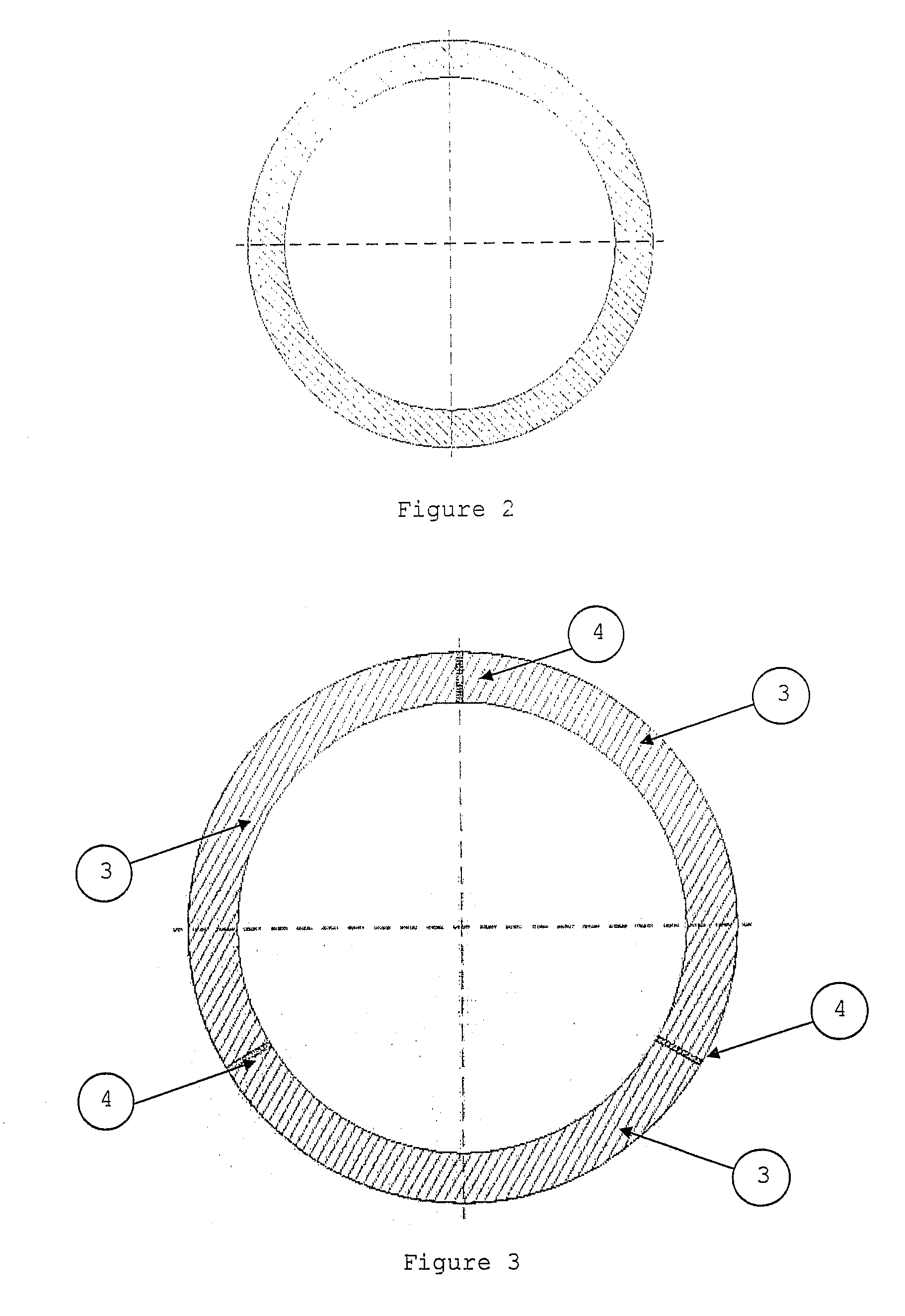

[0022]The tower, according to the invention, is built of two or more superimposed ring sections in conical or cylindrical form, each ring being built of one or more shell segments, these segments are joined by means of mechanical and / or chemical bonding and made of pre-cast polymeric concrete.

[0023]The segments are moulded after mixture of the binder and filler materials, as described above. The binder is a thermosetting resin like polyester resin, epoxy resin, phenolic resin, vinyl ester resin or others. Before filling the moulds with polymer concrete, chopped fibres mixed with the thermosetting resin can be sprayed onto the mould external wall, to enhance the tensile resistance of the segment.

[0024]The rings have specially designed ends in order to assemble into each other when building a tower. Between two superimposed rings, as seen in FIG. 4, the one in the bottom has the top end shaped like a step with, from the interior to the exterior, first a bottom horizontal surface (12),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com