Sheet feeding apparatus and image forming apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0029]Now, a preferred embodiment of the present invention will be described in detail with reference to the drawings. In the description, the present invention is implemented in an electro-photographic image forming apparatus, but the size, material, shape, relative configuration and the like disclosed in the present embodiments are not intended to restrict the scope of the present invention in any way.

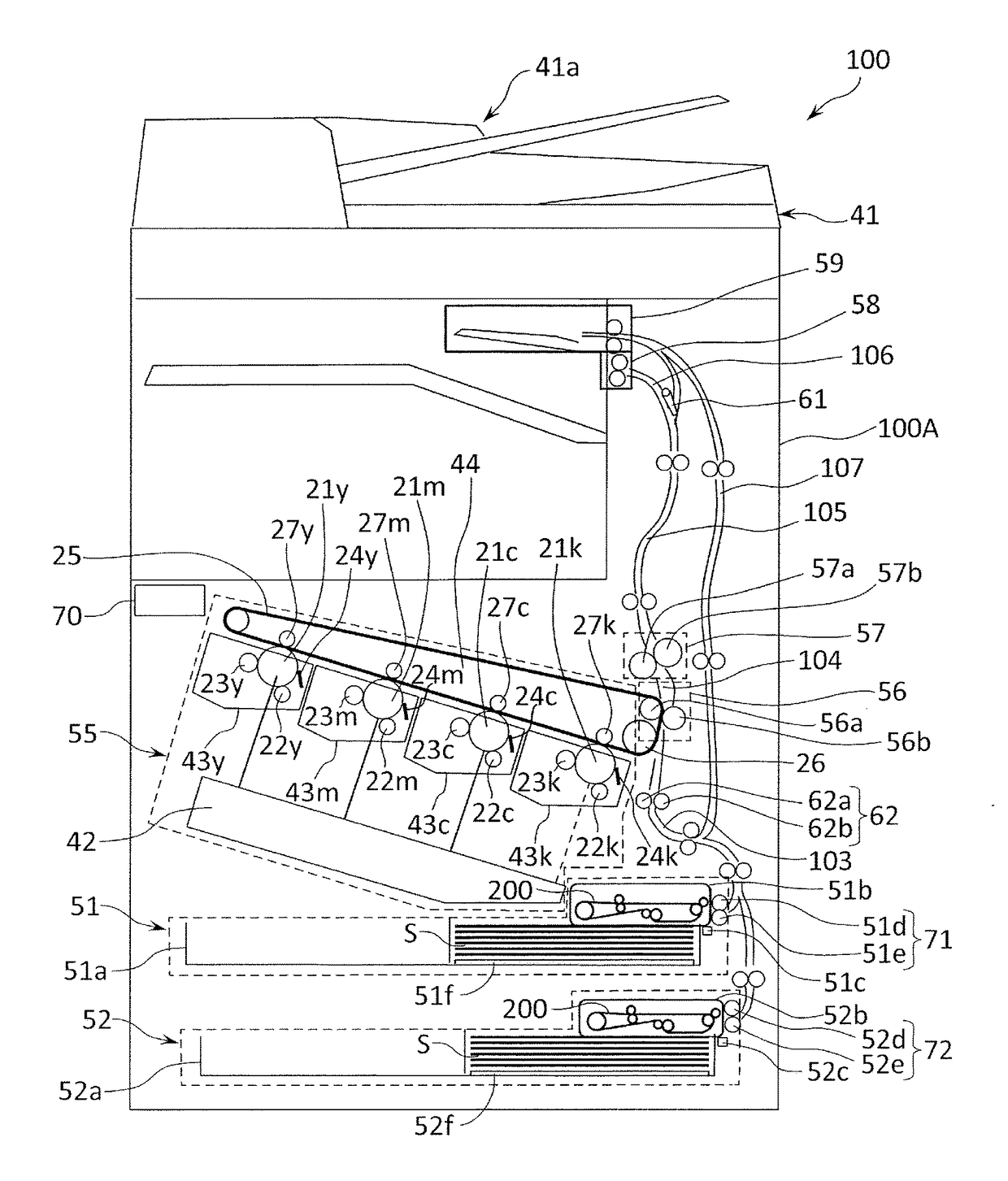

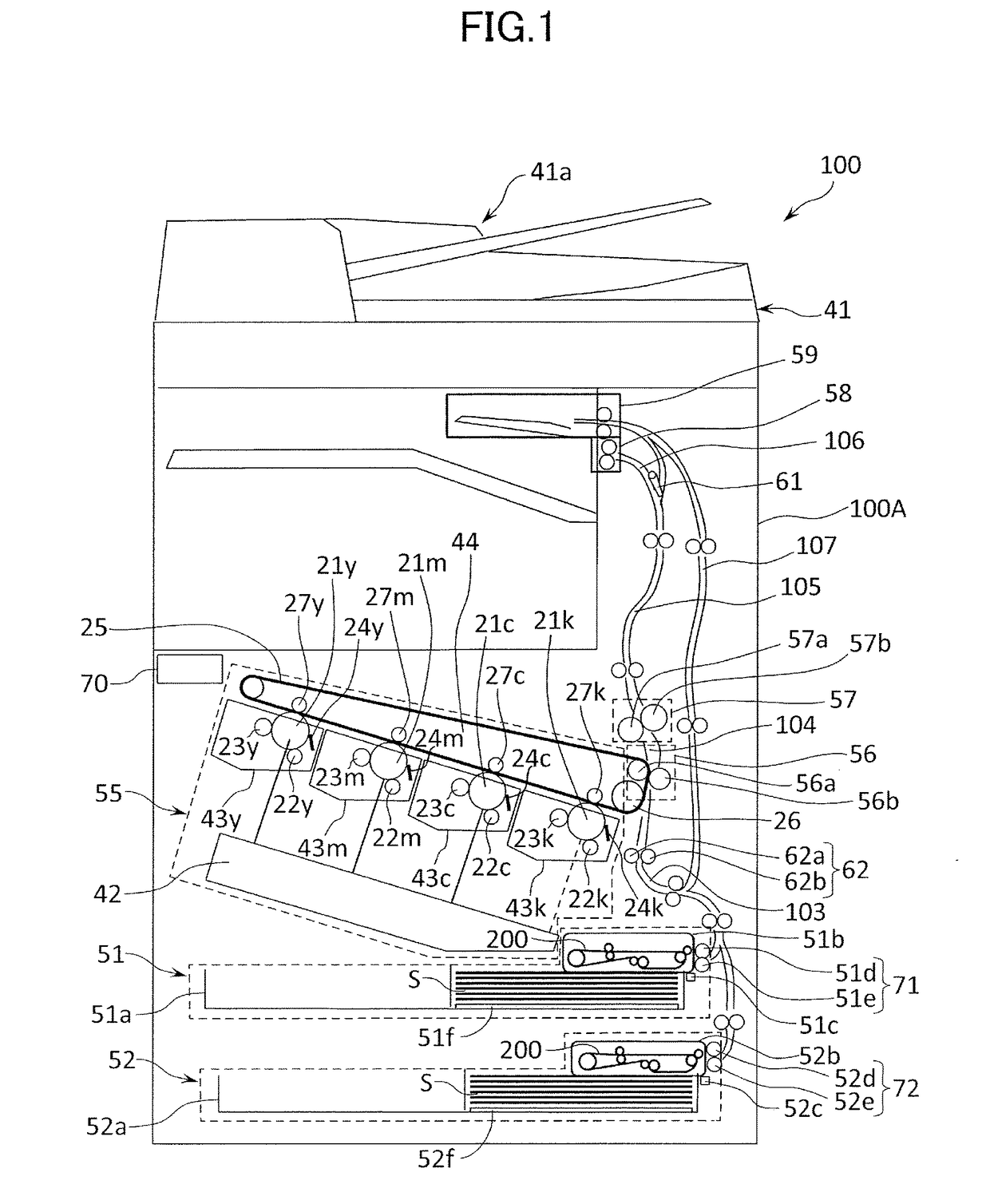

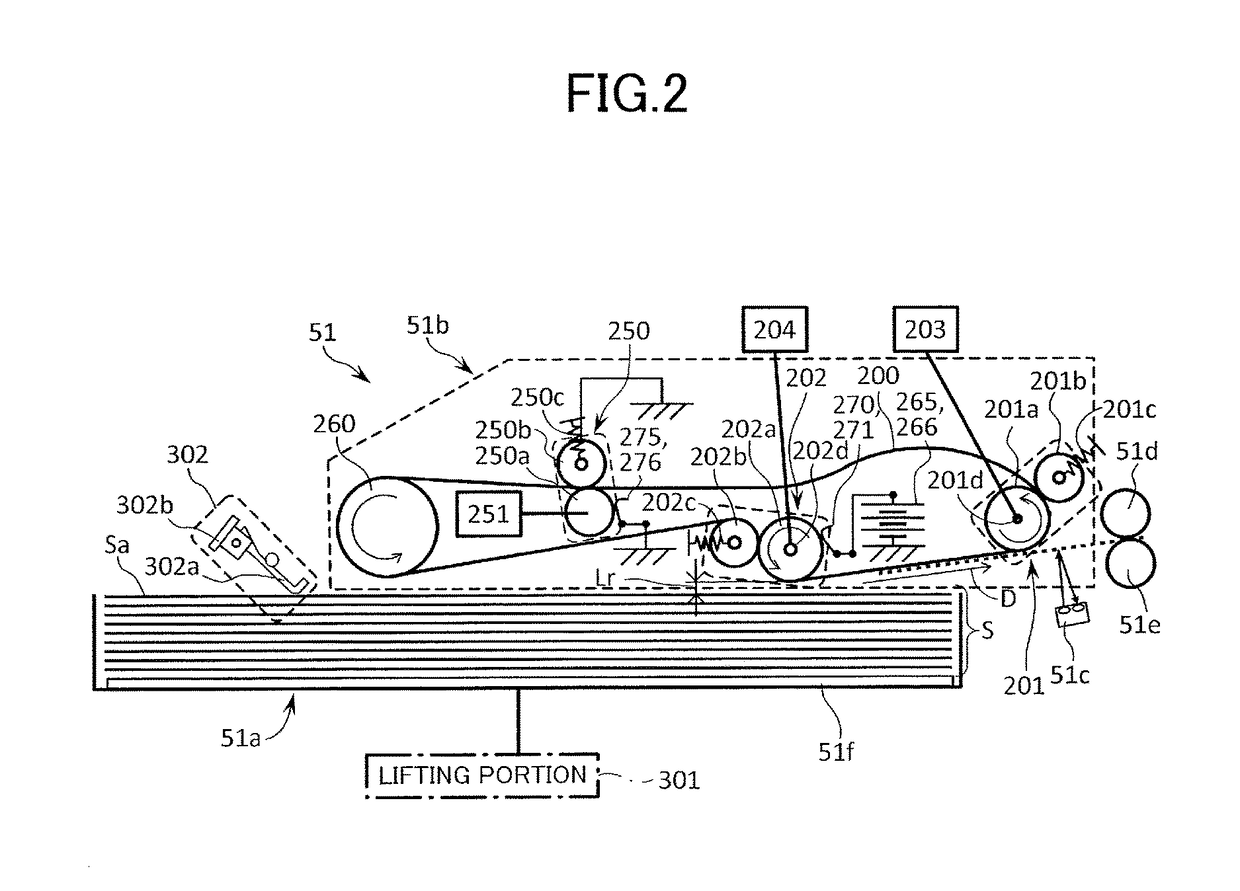

[0030]FIG. 1 is a schematic view illustrating the image forming apparatus having a sheet feeding apparatus according to the present embodiment. In FIG. 1, 100 denotes the image forming apparatus, and 100A denotes an image forming apparatus body (hereinafter referred to as apparatus body). On the upper portion of the apparatus body 100A is arranged an image reader 41, which irradiates light onto a document placed on a platen glass as a document positioning plate and has an image sensor and the like that converts reflected light into digital signals. The apparatus body 100A includes a ...

second embodiment

[0144]Now, a second embodiment of the present invention will be described with reference to FIGS. 12 to 17. In the present embodiment, the same components as the first embodiment are denoted with the same reference numbers, and the descriptions of components having the same configuration and function are omitted.

[0145]In the first embodiment described earlier, power feed to the attraction member 200 is performed from the positive voltage supply portion 265 and the negative voltage supply portion 266 through the first nipping-conveying inner roller 202a, but in the present embodiment, in addition to the above, power is also fed from the second nipping-conveying inner roller 201a.

[0146]FIG. 12 is a view illustrating an configuration of the sheet feeding apparatus 51 according to the present embodiment. In the present embodiment, the positive voltage supply portion 265 and the negative voltage supply portion 266 are connected to both the first nipping-conveying inner roller 202a and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com