Sheet manufacturing apparatus, sheet manufacturing method, sheet manufactured with the same, composite used therewith and accommodation container therefor

a technology of sheet manufacturing and equipment, which is applied in the direction of paper recycling, textiles and paper, non-woven fabrics, etc., can solve the problems of difficult to respond to modern demands for energy saving, environmental protection, and the like, and the apparatuses used in pulp molding often need large scale utilities and infrastructure. , to achieve the effect of reducing the coagulation of the composites to each other, reducing the coagulation, and facilitating the separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

11.1. Example 1

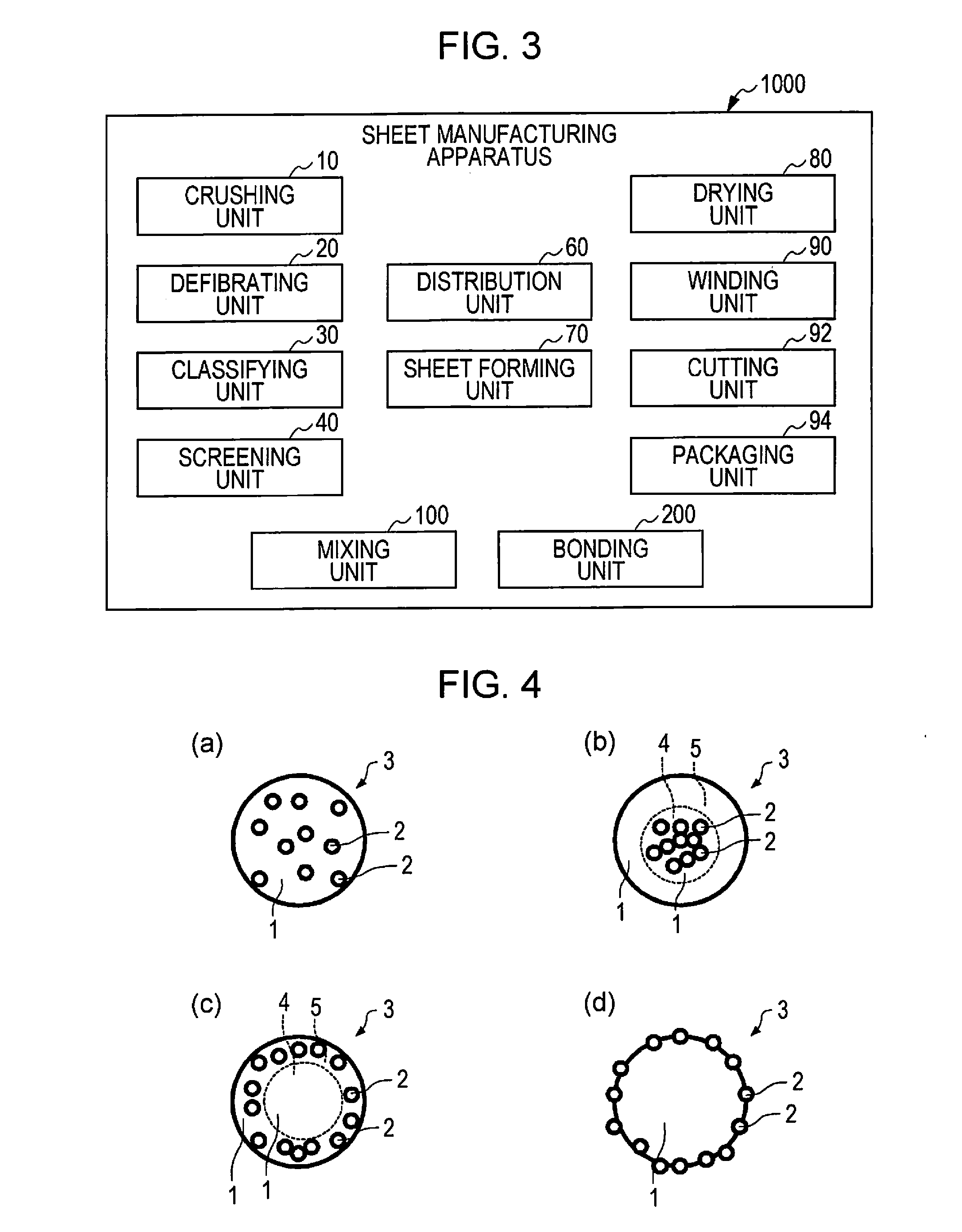

(1) Structure of Composite Integrally Including Resin and Coloring Material

(Integration of Coloring Material to Resin)

[0154]1700 parts of polyester resin (manufactured by Toyobo Co., Ltd, brand name “Vylon 220”, glass-transition temperature: 54° C., softening point: 96° C.), and 300 parts of blue copper phthalocyanine (manufactured by Toyo Color Co., Ltd., brand name Lionol Blue FG-7330) were processed with a high speed mixer (manufactured by Nippon Coke & Engineering Co., Ltd, brand name “FM-type mixer FM-10C”), and a resin-pigment mixture was obtained. The resin-pigment mixture was supplied from the hopper of a twin screw kneading extruder (manufactured by Toshiba Machine Co., Ltd., trade name “TEM-26SS”), melt-kneading was performed, and the result was pelletized to obtain tablets with a diameter of approximately 3 mm. Since there is no phenomenon of the resin detaching from the time of pelletizing, it is determined that the resin and the coloring material are inte...

example 2

11.2. Example 2

(1) Structure of Composite Integrally Including Resin and Coloring Material

(Integration of Coloring Material to Resin)

[0161]Pellets were obtained similarly to Example 1.

(Size Adjustment of Composite)

[0162]Up to obtaining the composite with a maximum particle diameter or 40 μm was performed similarly to Example 1. The composite was classified by an airflow classifier (manufactured by Nippon Pneumatic Mfg. Co., Ltd., brand name “MDS-3”), and the volume average particle diameter d of the composite was made 20 μm.

(2) Coating Composite with Coagulation Inhibitor

[0163]This was the same as Example 1.

(3) Fiber

[0164]This was the same as Example 1.

(4) Manufacturing of Mixed Material

[0165]This was the same as Example 1.

(5) Manufacturing of Sheet

[0166]This was the same as Example 1.

example 3

11.3. Example 3

(1) Structure of Composite Integrally Including Resin and Coloring Material

(Integration of Coloring Material to Resin)

[0167]This was the same as Example 1.

(Size Adjustment of Composite)

[0168]This was the same as Example 1 (10 μm).

(2) Coating Composite with Coagulation Inhibitor

[0169]This was the same as Example 1.

(3) Fiber

[0170]Kraft paper (manufactured by Oji Materia Co., Ltd., brand name “OK Unbleached Kraft”) was cut into paper pieces with a width of 10 mm and a length of 30 mm and linear fibers were obtained by processing these in a dry type pulp defibrating machine (manufactured by Kumagai Riki Kogyo Co., Ltd., No. 2535) at room temperature. The linear fibers were spread on a metal sieve with an opening size of 5 mm, and used with the undefibrated material mixed into the fibers removed. The fiber diameter of the fibers was 33 μm (below, these fibers are denoted as Y).

(4) Manufacturing of Mixed Material

[0171]5 parts by weight of the composite obtained with (2) abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com