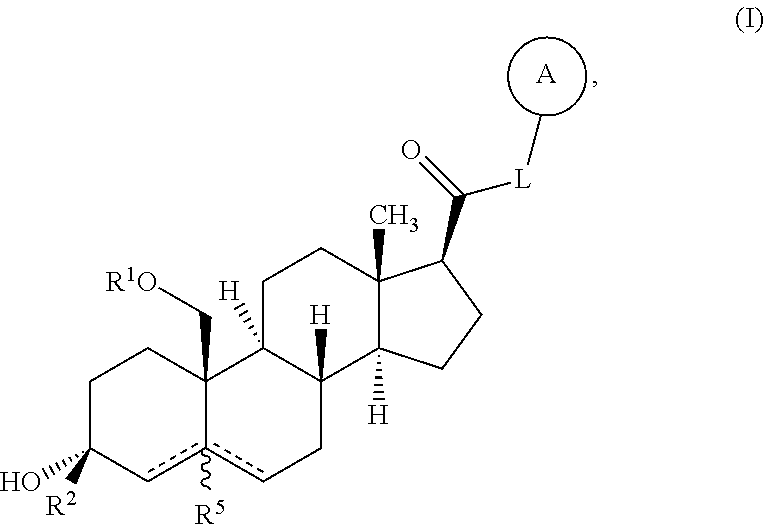

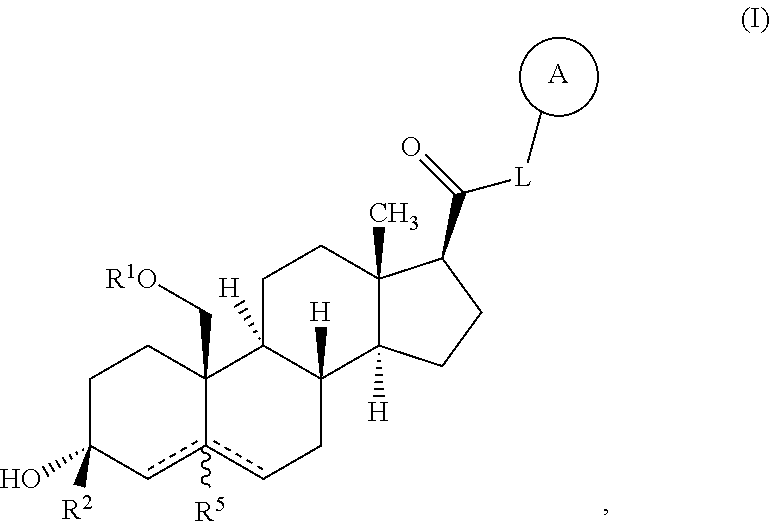

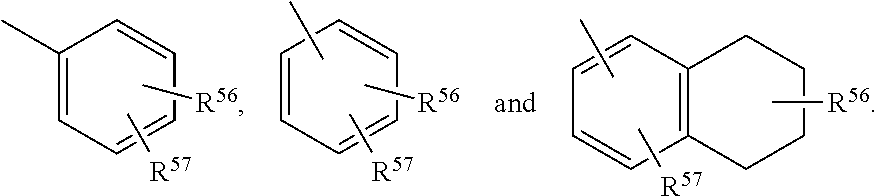

Neuroactive steroids, compositions, and uses thereof

a technology of neuroactive steroids and compositions, applied in the field of neuroactive steroids, compositions, can solve the problems that progesterone is not consistently effective in the treatment of the aforementioned syndromes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

General Procedure A: Preparation of A / B-Trans Scaffolds

[0234]

Step 1. Preparation of Compound A2.

[0235]Finely-ground potassium hydroxide (28.0 g, 165 mmol) was added to a solution of commercially available 19-hydroxyandrost-4-ene-3,17-dione (A1, 50.0 g, 165 mmol) in anhydrous 1,2-dimethoxyethane (500 mL) at 0° C. under nitrogen, after which methyl sulfate (43.7 g, 208 mmol) was added portionwise. The mixture was slowly warmed to room temperature, stirring for a total of 18 h, at which point TLC analysis of the mixture (7:3 hexanes / ethyl acetate) indicated completion of the reaction. The mixture was diluted with water (500 mL) and extracted with ethyl acetate (3×200 mL). The combined organic extracts were washed with saturated aqueous sodium chloride solution (100 mL), dried with anhydrous sodium sulfate and filtered. The solvents were removed under reduced pressure and the residue was purified by column chromatography on silica gel, eluting with heptane / ethyl acetate (2:1), to provid...

example 2

General Procedure A: Preparation of A / B-Trans Scaffolds

[0245]

Step 1. Preparation of Compound A12.

[0246]Prepared according General Procedure A, Step 1 from A1, 10.0 g, 33 mmol) and ethyl sulfate (17.3 mL, 132 mmol), with purification by column chromatography on silica gel to provide compound A12 as a yellow oil (4.6 g, 42%).

Step 2. Preparation of Compound A13.

[0247]Prepared according General Procedure A, Step 2 from compound A12 (4.6 g, 14 mmol) to provide crude compound A13 as a yellow oil that was used in the next step without further purification.

Step 3. Preparation of Compound A14.

[0248]Prepared according General Procedure A, Step 3 from crude compound A13, with purification by column chromatography on silica gel to provide compound A14 as a yellow oil (1.5 g, 31%).

Step 4. Preparation of Compound A15.

[0249]Prepared according General Procedure A, Step 4 from compound A14 (1.7 g, 5.1 mmol) to provide crude compound A15 as a yellow oil that was used in the next step without further ...

example 3

General Procedure B: Preparation of A / B-Trans Scaffold C-21 Analogs

[0256]

[0257]5-Chloro-1H-benzo[d][1,2,3]triazole (470 mg, 3.06 mmol) and potassium carbonate (704 mmol) 5.1 mmol) were added to a solution of compound A11 (225 mg, 0.51 mmol) in anhydrous tetrahydrofuran (20 mL) at room temperature under nitrogen and the mixture was stirred for 16 h, at which point TLC analysis of the mixture (2:1 hexanes / ethyl acetate) indicated completion of the reaction. The mixture was diluted with water (120 mL) and extracted with ethyl acetate (3×100 mL). The combined organic extracts were washed with saturated aqueous sodium chloride solution (60 mL), dried with sodium sulfate and filtered. The solvents were removed under reduced pressure and the residue was semi-purified by column chromatography on silica gel, eluting with hexanes / ethyl acetate (3:1), to provide a mixture of the three regioisomers. The residue was further purified by reverse phase preparative HPLC to provide 35 as an off-white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| membrane voltage | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com