Collector pipe for a heat exchanger device, a heat exchanger device and a method for emptying a heat exchanger device

a technology of heat exchanger and collector pipe, which is applied in the direction of heat exchange apparatus, stationary tubular conduit assembly, stationary conduit assembly, etc., can solve the problems of high material and processing costs, many tubes are required, and the degree of efficiency is normally associated with higher costs. , the effect of reducing the temperature differen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

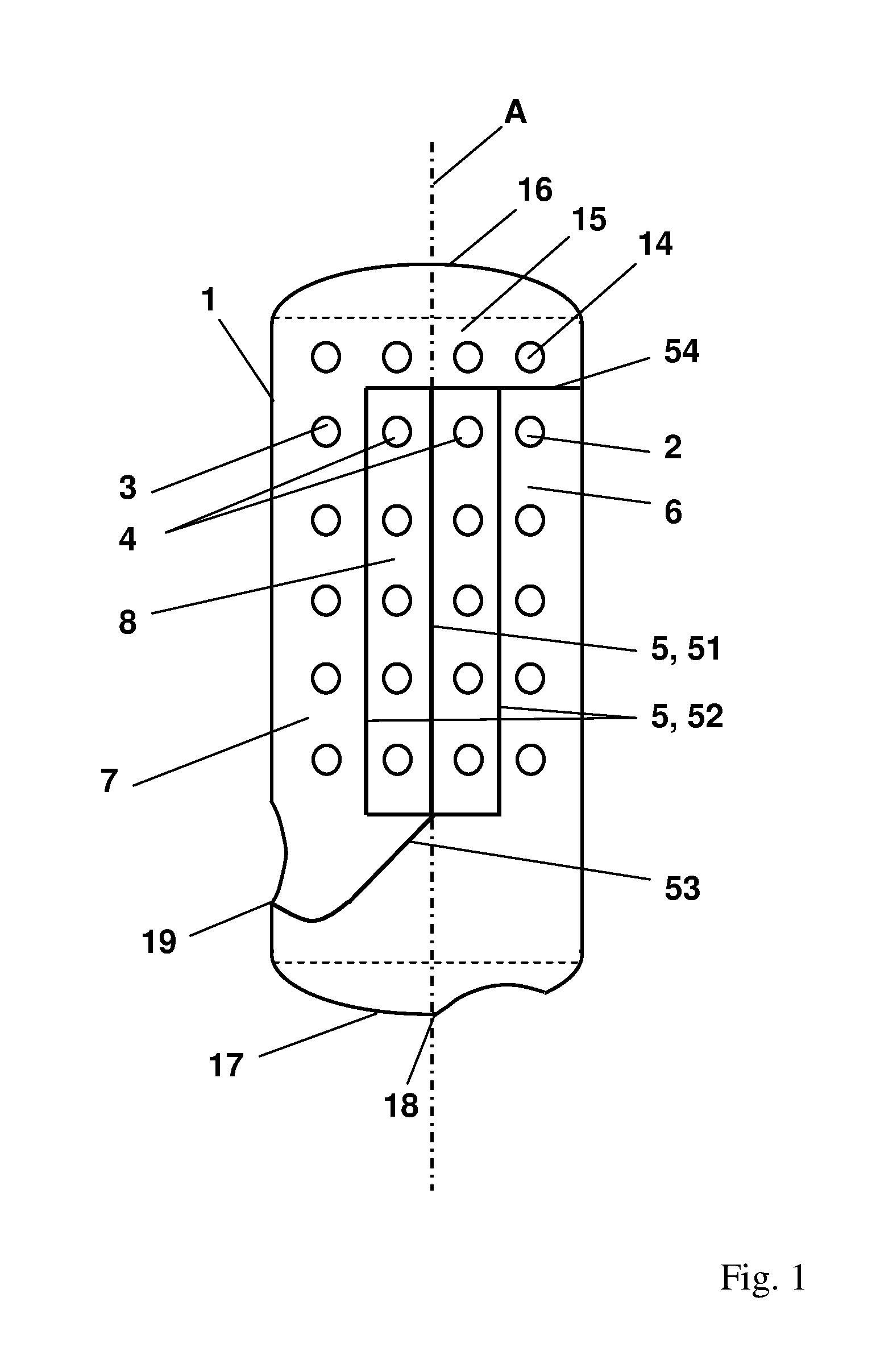

[0062]FIG. 1 shows a schematic illustration of the collection tube 1 in accordance with the invention. The collection tube 1 is configured as a generally hollow cylindrical tube, in particular as a hollow circular cylinder, which is open at a first and at a second axial end. The collection tube 1 comprises an outflow opening 2, an inflow opening 3 and a plurality of deflection openings 4. The outflow opening or the inflow opening or the deflection openings 2, 3, 4 are configured as an opening in a jacket surface of the collection tube 1. A plurality of outflow openings 2 are arranged vertically above one another, preferably having the same spacing at a first plane. Likewise a plurality of inflow openings or deflection openings 3, 4 are arranged vertically above one another, preferably having the same spacing, at a parallel first plane. The outflow opening or the inflow opening or the deflection openings 2, 3, 4 are horizontally arranged next to one another, preferably having the sam...

second embodiment

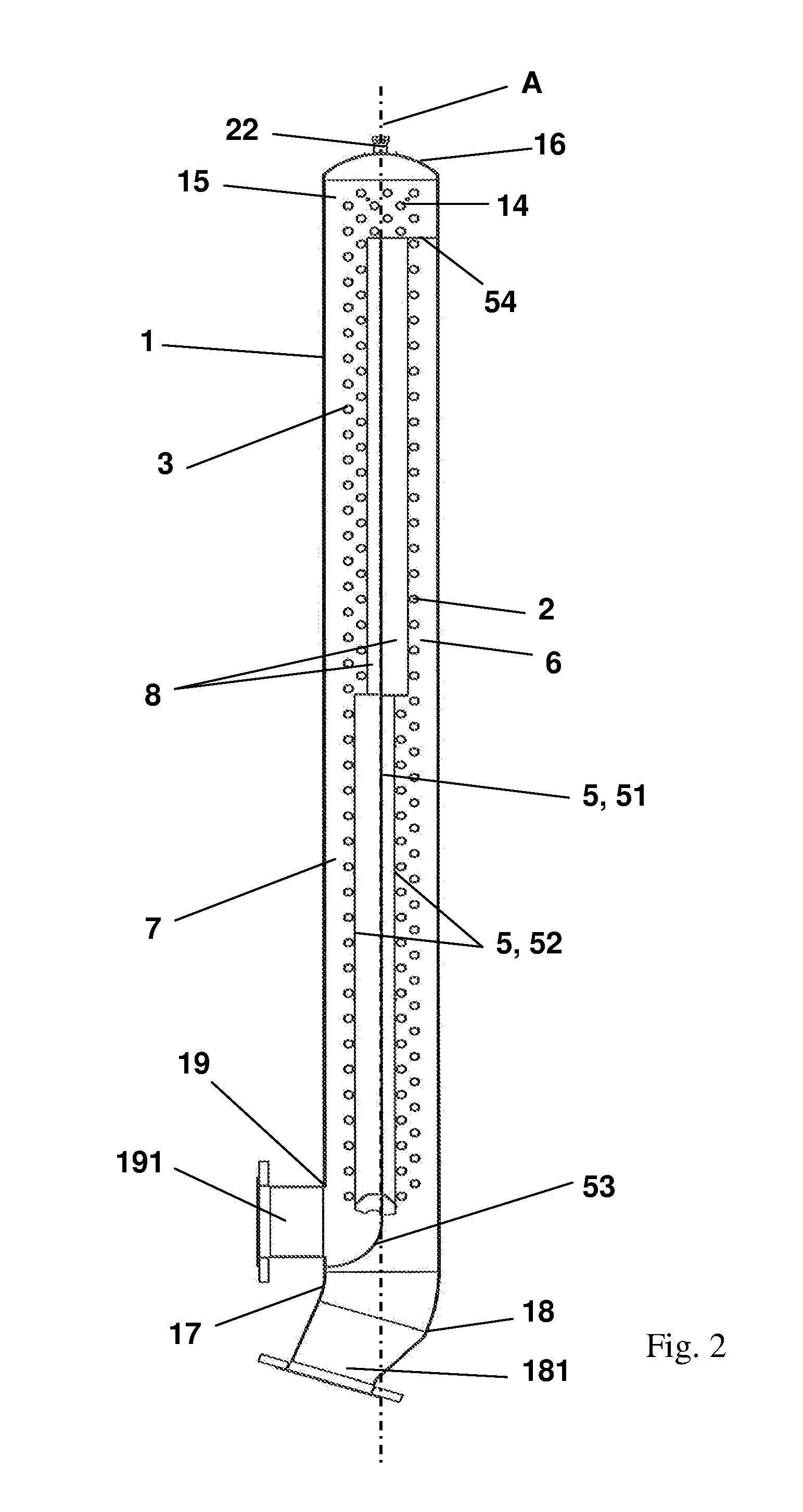

[0067]A schematic illustration of the collection tube 1 is illustrated in FIG. 2. The assembly of the collection tube 1 in this connection has many similarities to the collection tube 1 of FIG. 1, for which reason reference is only made to the differences. The first termination element 16 further comprises a compensation opening 22, wherein air flows into the collection tube for an open compensation opening 22. The separation element 5 is of two-part design, wherein the two parts of the separation element 5 are horizontally displaced with respect to one another so that the separation element 5 divides a like number of outflow openings, inflow openings and deflection openings 2, 3, 4 in a radial direction of the collection tube axis A. An inflow 191 is further arranged at the inflow opening 19 and an outflow 181 is further arranged at the outflow opening 18.

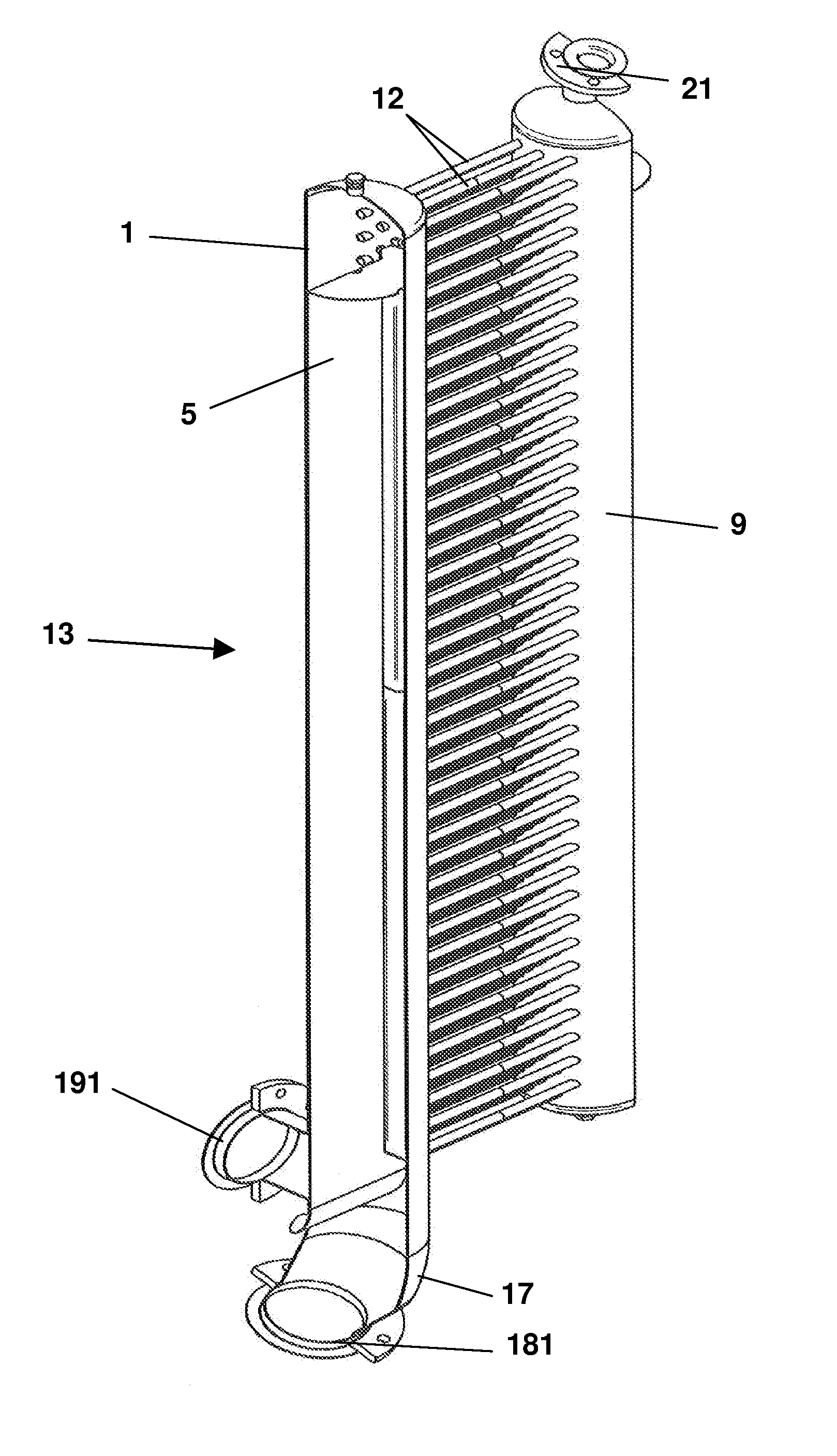

[0068]A schematic illustration of a first embodiment of a deflection tube is illustrated in FIG. 3. The deflection tube 9 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com