Composite filament textile and environment-friendly composite filament artificial leather manufactured using the same

a composite filament and textile technology, applied in the field of artificial leather and textiles, can solve the problems of unstable dimensional stability of the base, unenvironmental protection, and inability to achieve the goal of lightweight, and achieve the effects of good dimentional stability, good abrasion, and good touch feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

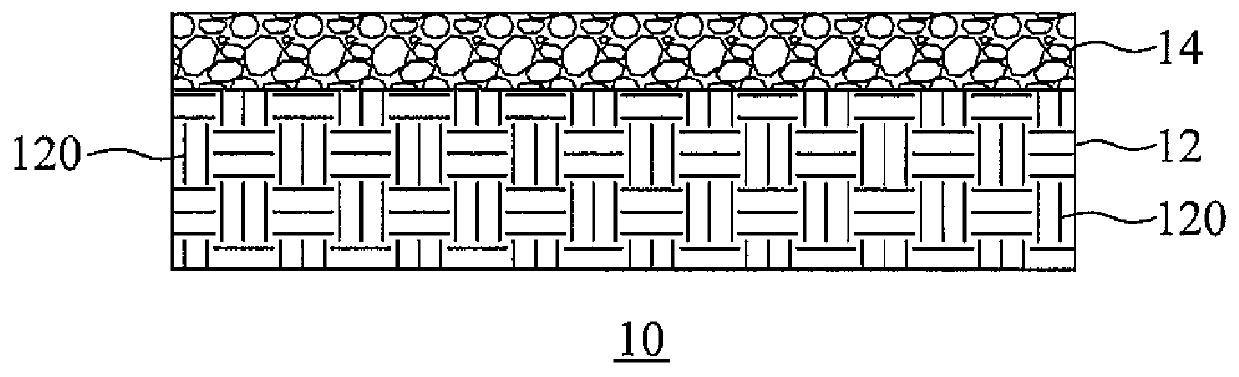

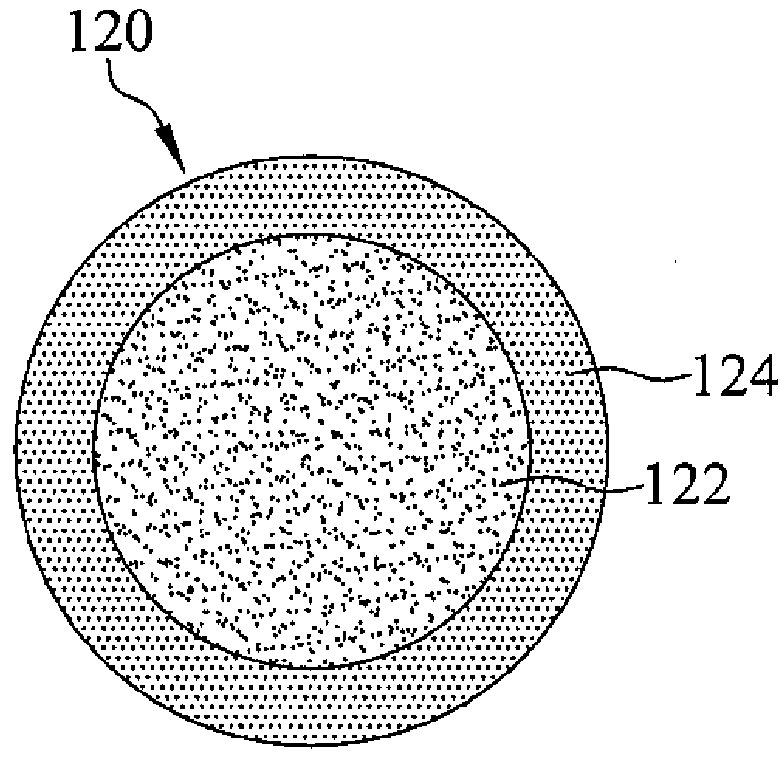

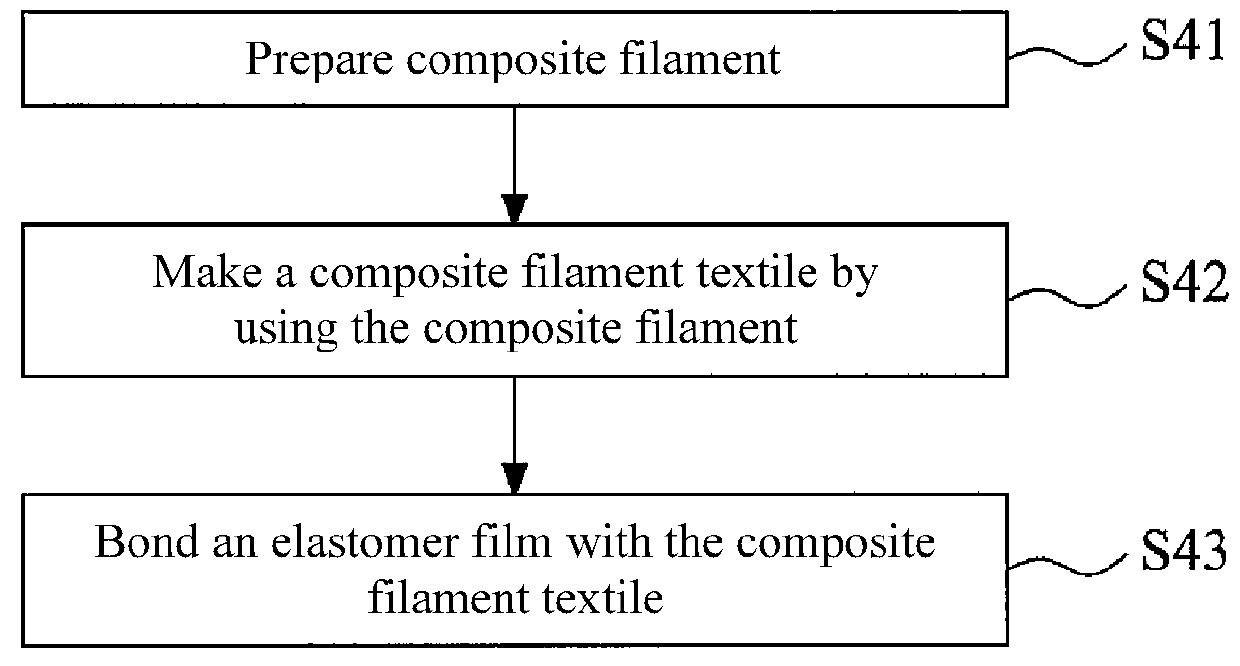

[0052]PBT (polybutylene terephthalate, IV=0.74) is taken as an ingredient of a core portion, TPU (thermoplastic polyurethane, MI=4, 190° C., 2.16 kg) is taken as an ingredient of a sheath portion, and a ratio of the weight of PBT to that of TPU is 6:4. Referring to FIG. 6, which shows a schematic diagram of a manufacturing process in which a filament composite spinning machine is used to prepare composite filament according to Embodiment 1. As shown in FIG. 6, the filament composite spinning machine is used to manufacture composite filament with a core-sheath section, the temperature in a PBT spinning box is 250° C., the temperature in a TPU spinning box is 220° C., the winding speed is 2500 m / min, and the composite filament with the specification of 100 den / 24 f and the single-fiber strength of 4 g / den can be obtained.

[0053]After the composite filament is arranged in order, the composite filament is woven by a loom into a fabric which the ends per inch (Warp rate) is 17 and the Pic...

embodiment 2

[0056]PET (polyethylene terephthalate, IV=0.5) is taken as an ingredient of a core portion, TPU (thermoplastic polyurethane, MI=50, 190° C., 2.16 kg) is taken as an ingredient of a sheath portion, and a ratio of the weight of PET to that of TPU is 6:4. Referring to FIG. 7, which shows a schematic diagram of a manufacturing process in which a spunbond composite fiber spinning machine is used to prepare composite filament according to Embodiment 2. As shown in FIG. 7, the spunbond composite fiber spinning machine is used to manufacture composite filament with a core-sheath section, the temperature in a PET spinning box is 260° C., the temperature in a TPU spinning box is 220° C., and spinning is performed through a spunbond process, wherein the air pressure is 9 kg / cm2, the wind induced yarn drawing speed is 4000 m / min, and the conveying belt speed is 4 m / min, so the composite filament with a diameter of 20 μm and a spunbond nonwoven textile with a thickness of 0.22 mm can be manufact...

embodiment 3

[0059]PTT (polytrimethylene terephthalate, IV=0.55) is taken as an ingredient of a core portion, TPU (thermoplastic polyurethane, MI=80, 190° C., 2.16 kg) is taken as an ingredient of a sheath portion, and a ratio of the weight of PTT to that of TPU is 6:4. Referring to FIG. 8, which shows a schematic diagram of a manufacturing process in which a melt-blown spinning machine is used to prepare composite filament according to Embodiment 3. As shown in FIG. 8, the melt-blown composite fiber spinning machine is used to manufacture composite filament with a core-sheath section, the temperature in a PTT spinning box is 250° C., the temperature in a TPU spinning box is 200° C., and spinning is performed through a melt-blowing process, wherein the high-pressure air pressure is 3000 psi, the high-pressure air temperature is 180° C., and the conveying belt speed is 2 m / min, so the composite filament with a diameter of 20 μm and a melt-blown nonwoven textile with a thickness of 0.27 mm can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com