Cmu cooling tower and method of construction

a technology of water cooling towers and water towers, applied in the direction of heating types, building repairs, separation processes, etc., can solve the problems of under-performing cooling towers, affecting the efficiency and therefore the operating costs of hvac and industrial systems, and replacing or supplemental cooling towers, so as to reduce the time of construction and operation, less heavy equipment, and less transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

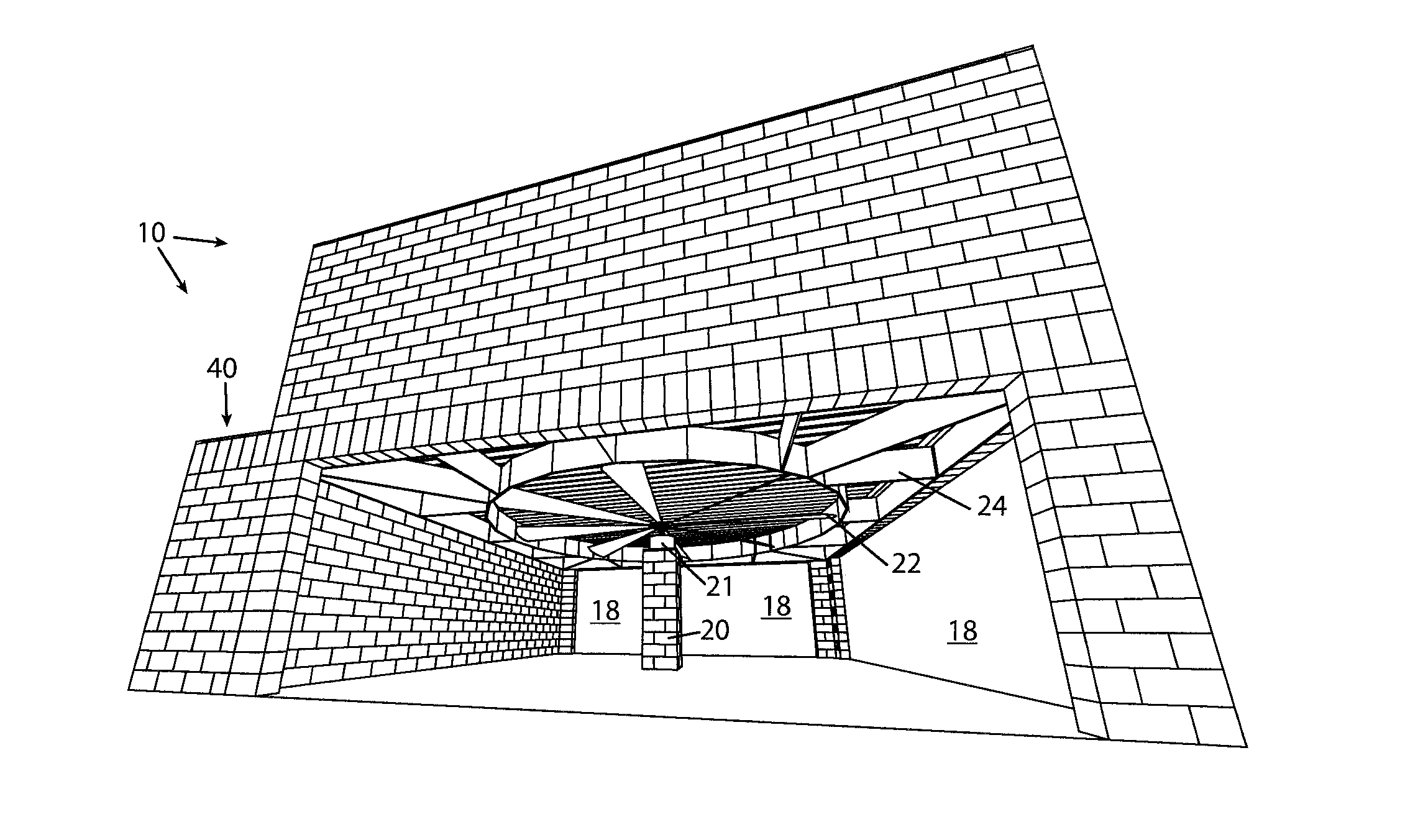

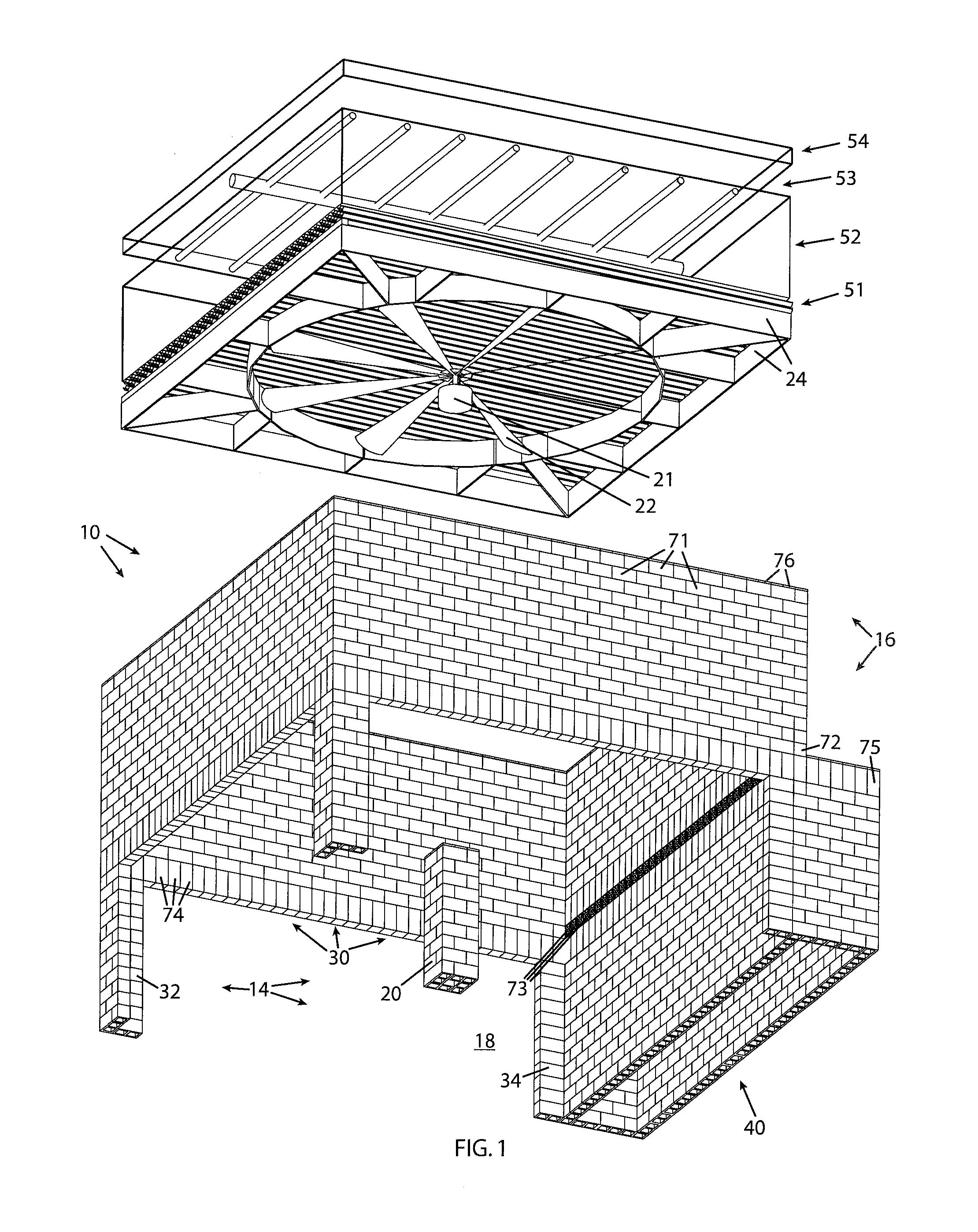

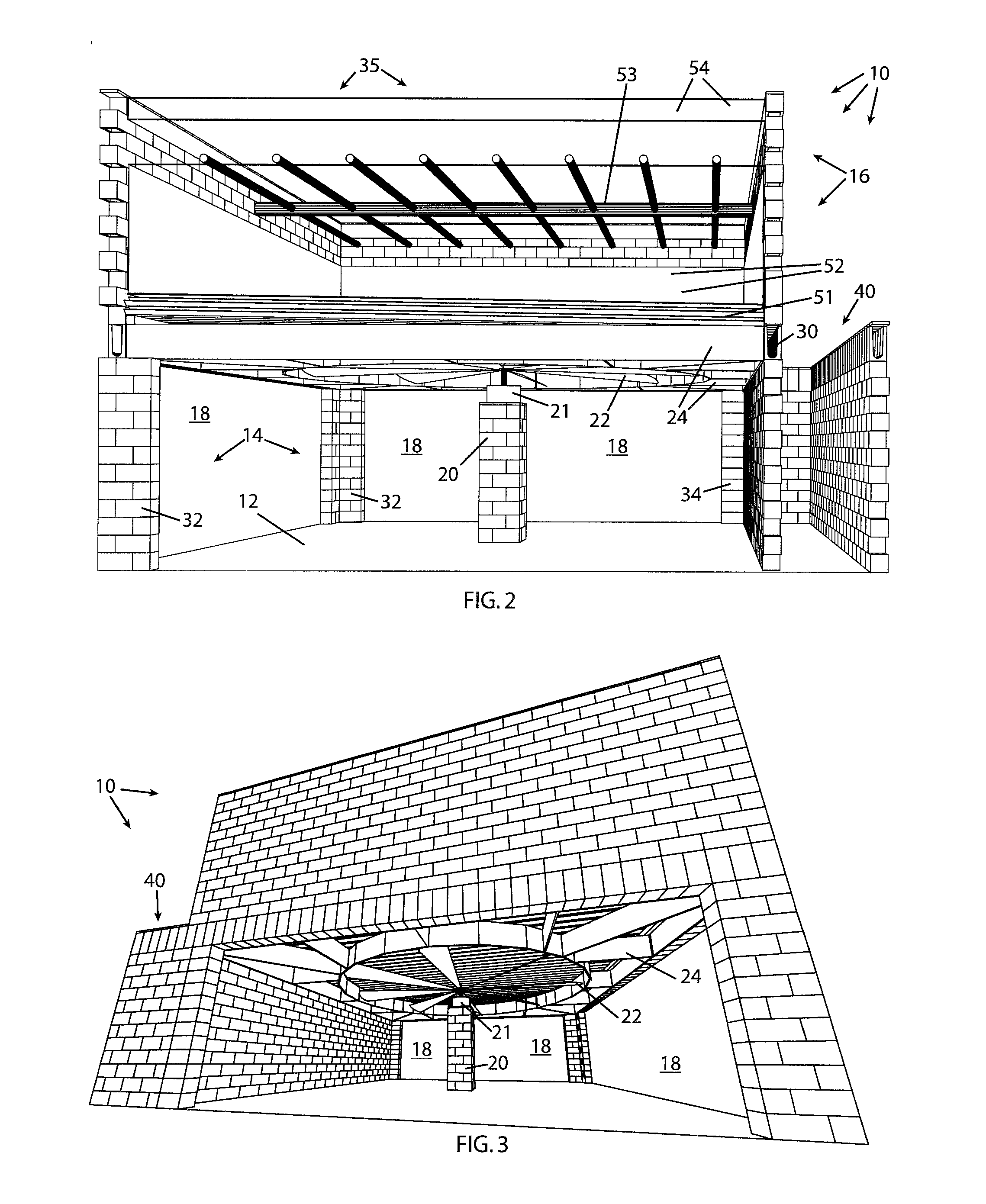

[0033]Referring to FIG. 1&FIG. 2 the counterflow type of cooling system known in the art comprises, from top to bottom, an optional drift eliminator 54 for the purpose of catching sprays and mists of water and retaining them in the cooling system, a nozzle array 53 that sprays water to maximize the available surface area of water droplets for evaporative cooling, a thick layer of porous fill media 52 to further spread out the water droplets and to prolong their exposure to the cooling stream of air, and a water collector 51 that catches and channels the cooled water but allows the flow of cooling air from below.

[0034]The forced-air counterflow type of cooling system known in the art further comprises a fan 22 driven by a fan motor 21 and surrounded by a fan shroud 24, with the fan assembly located below the rest of the cooling system, which puts the fan assembly closer to the ground or mounting surface, which is advantageous for maintenance purposes and for weight-distribution purpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com