Monobenzoate useful as a plasticizer/coalescent in polymeric dispersions

a polymer dispersible and monobenzoate technology, applied in the field of monobenzoate, can solve the problems of poor plant air quality, affecting the air quality around the film, and affecting the work environment, and achieve the effect of reducing the voc content and improving the work environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0081]The evaluation of the plasticizers / coalescents consisted of a variety of experiments. First, VOC's of the neat plasticizers / coalescents selected were determined. Then, effectiveness and efficiency of the coalescents with a traditional polymer were determined using simple binary blends.

[0082]In another segment, a starting basic OPV formulation was prepared to assess the effect of the new plasticizer in an actual OPV. In yet another segment, the coalescent performance in a simple waterborne model ink formulation was evaluated. Inks were then coated with the experimental OPV's and evaluated.

[0083]Other evaluations involved the use of the inventive monobenzoate in adhesives and plastisols and are set forth herein below.

examples 1-4

OPV and Inks

[0084]The polymer selected for use in the OPV / ink examples was a traditional high Tg, hard styrene acrylic emulsion a standard in the graphic arts industry, although it is expected that the present inventive coalescent would be useful in a large number of polymeric dispersions used in this industry. Such polymers would be known to one skilled in the art. The polymer was utilized in all of the simple starting formulations set forth herein.

[0085]The following plasticizers / coalescents were selected for evaluation in the examples (in whole or part):[0086]2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate (TMPDMB). This coalescent is historically the traditional coalescent of choice in paint and other coatings but not necessarily in OPV's or inks.[0087]2-Ethylhexyl benzoate (2-EHB). This coalescent was introduced a few years ago as a new lower VOC type coalescent.[0088]Butyl Carbitol™ diethylene glycol monobutyl ether (BC)[0089]Carbitol™ diethylene glycol monomethyl ether (C)[00...

example 1

VOC / Volatility of Neat Plasticizers / Coalescents

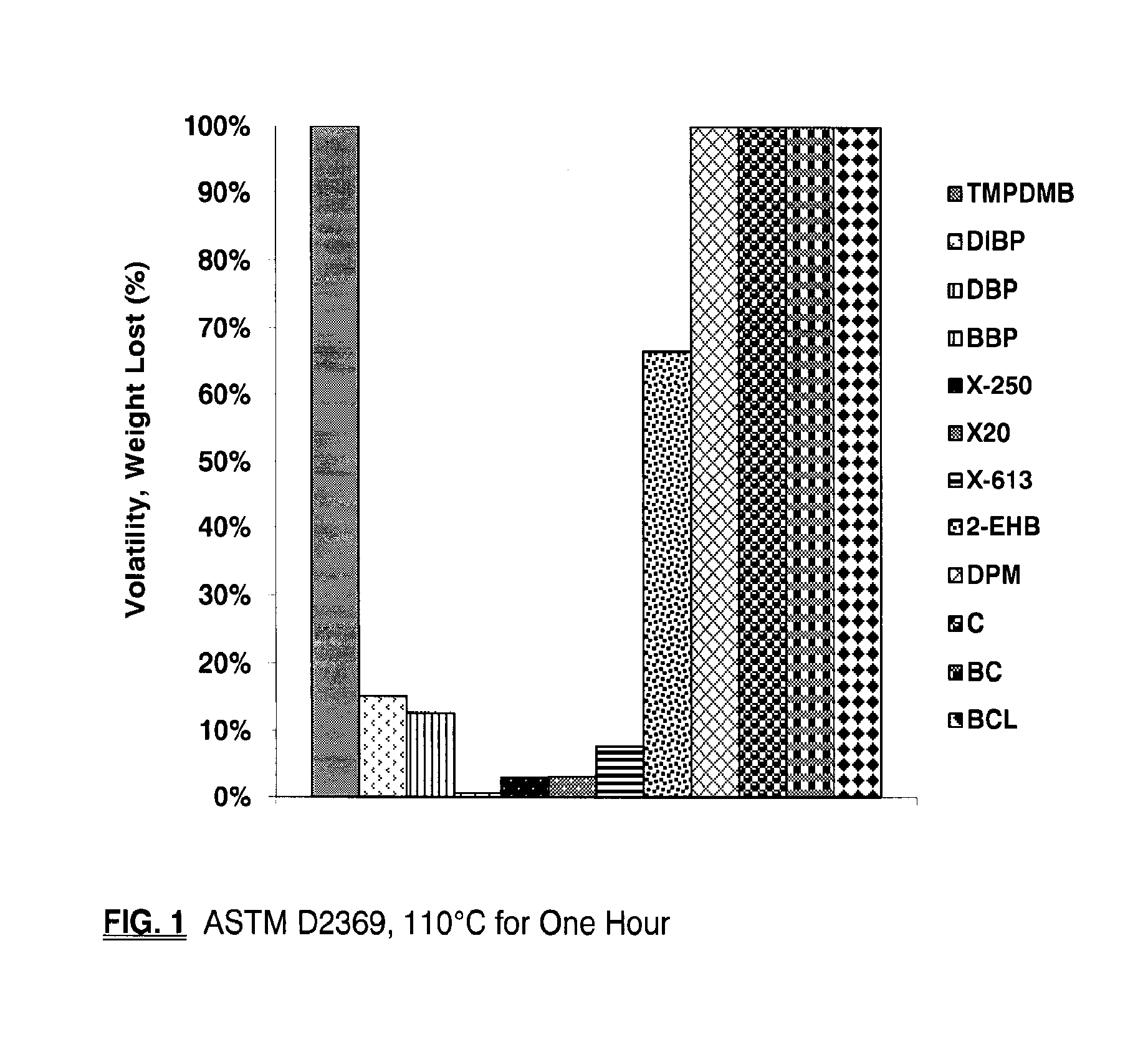

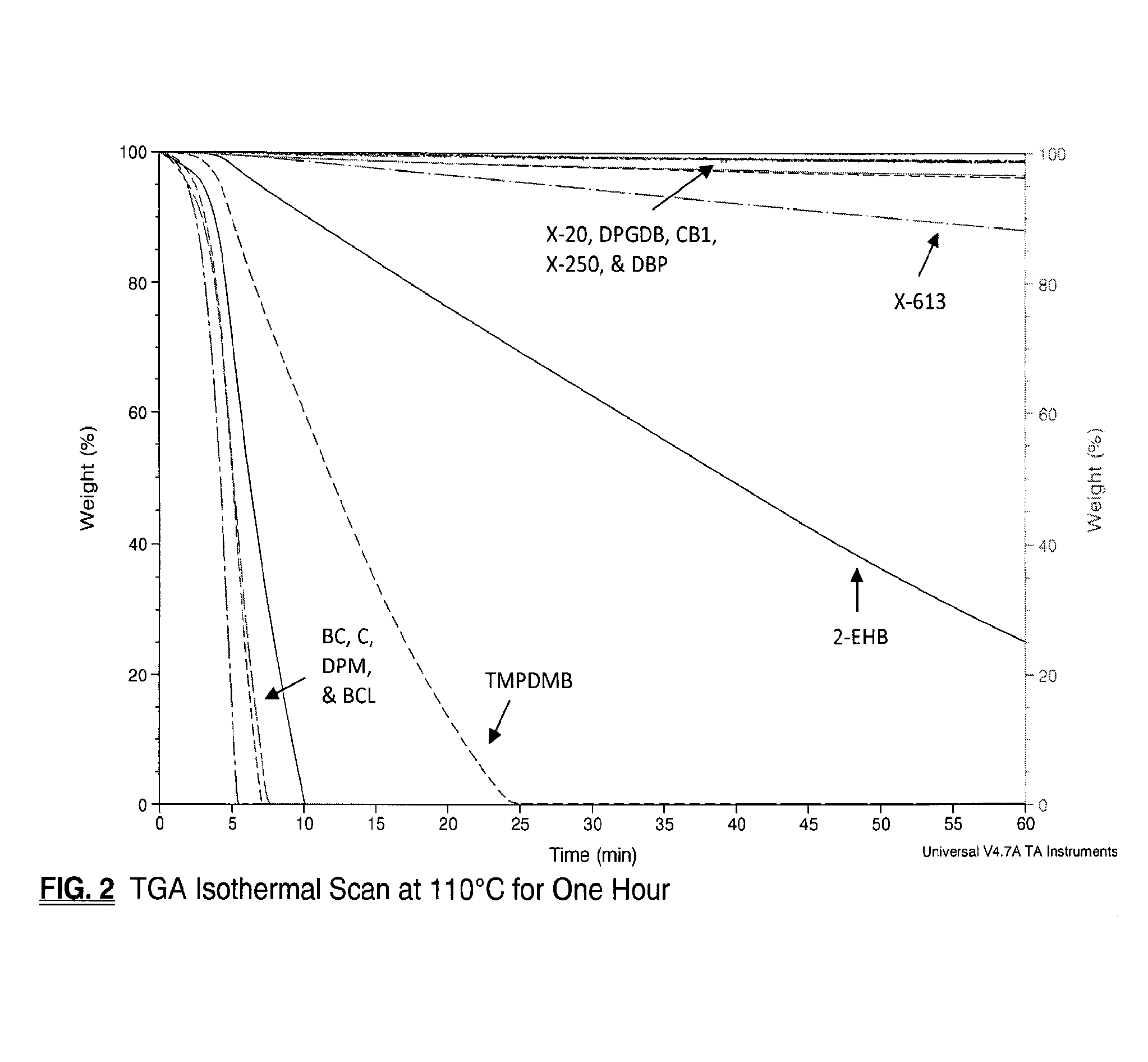

[0132]FIGS. 1 and 2 illustrate the volatility characteristics determined for the neat plasticizers / coalescents evaluated. Traditional ether coalescents were definitely volatile. The plasticizers of the evaluation were all low in volatility and, thus, would not contribute significantly to the overall VOC of a formulation at typical levels of use. Conversely, the coalescents that were 100% volatile will contribute significantly to the total VOC release.

[0133]Of the benzoate coalescents evaluated, other than 2-EHB, the TGA scan data shows that the monobenzoate of the invention, X-613 (3-PPB), was the most volatile, However, X-613 was significantly lower in VOC content than the older traditional high VOC coalescents. All of the plasticizers / coalescents of the evaluation were considerably lower than 20% volatile compared to the ethers, TMPDMB and 2-EHB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com