Multicomponent aliphatic polyester blend fibers

a technology of polyester blend and aliphatic polyester, which is applied in the field of multi-component thermoplastic fibers, can solve the problems of reducing the temperature at which satisfactory bonding can occur, and achieve the effects of reducing temperature, reducing viscosity of the first polymer component, and increasing melt flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

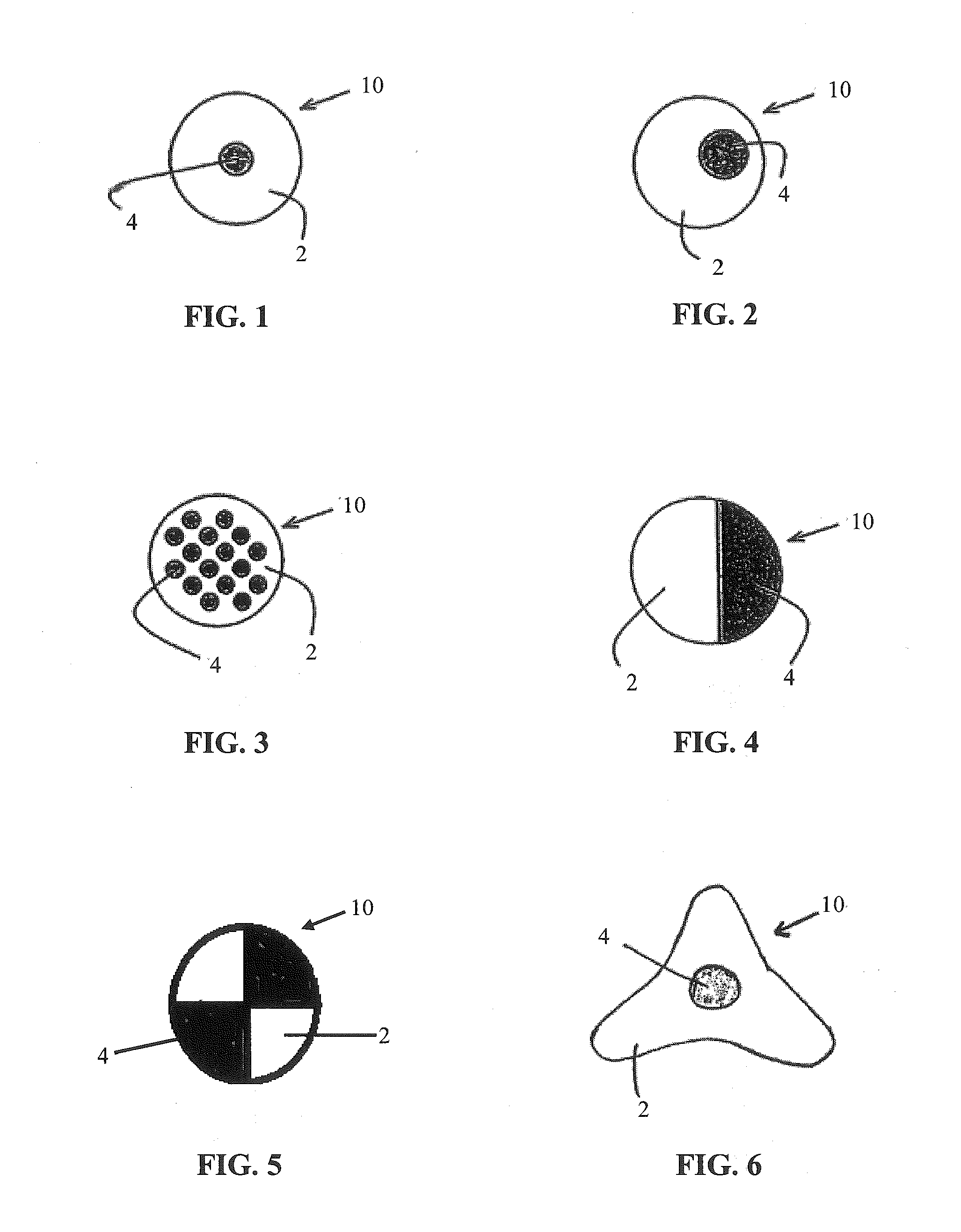

Image

Examples

example

[0070]An exemplary, non-limiting PLA binder fiber bonding test is described, such that the sensitivity of bond strength to bonding temperature at a 12 second dwell time in the bonding oven of a carded nonwoven fabric comprising 75% PLA 6202 fibers (available from NatureWorks, LLC) and 25% experimental binder fibers can be determined. Each test sample (a carded nonwoven fabric measuring 3 inches by 2 inches, with the 2 inch dimension in the direction of carding (i.e., parallel to the fiber direction) can be prepared as follows. First, 1.5 g of crimped PLA staple fiber made using Natureworks grade 6202D, 2 denier per filament, 1.5 inch cut length (the “matrix” fiber) can be prepared. Also, 0.5 g of binder fiber (as disclosed herein) can be weighed. The two fiber samples are placed on a hand card, being careful to distribute both fibers as evenly across the card as possible. Ideally, the matrix fiber goes onto the card first, since the experimental fiber may be uncrimped and thus is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bonding temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com