Method and automated system for control of oil well production and modular skid for use in said method

an automated system and oil well technology, applied in the direction of gas/liquid distribution and storage, water supply installation, fluid removal, etc., can solve the problems of liquid level using a measuring tape, reducing the validity of extrapolation procedures, and challenging filling the control tank, so as to improve the measurement of well production and reduce errors , the effect of reducing the overall size of surface installations and reducing the testing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]The invention will be described in detail below with reference to the figures.

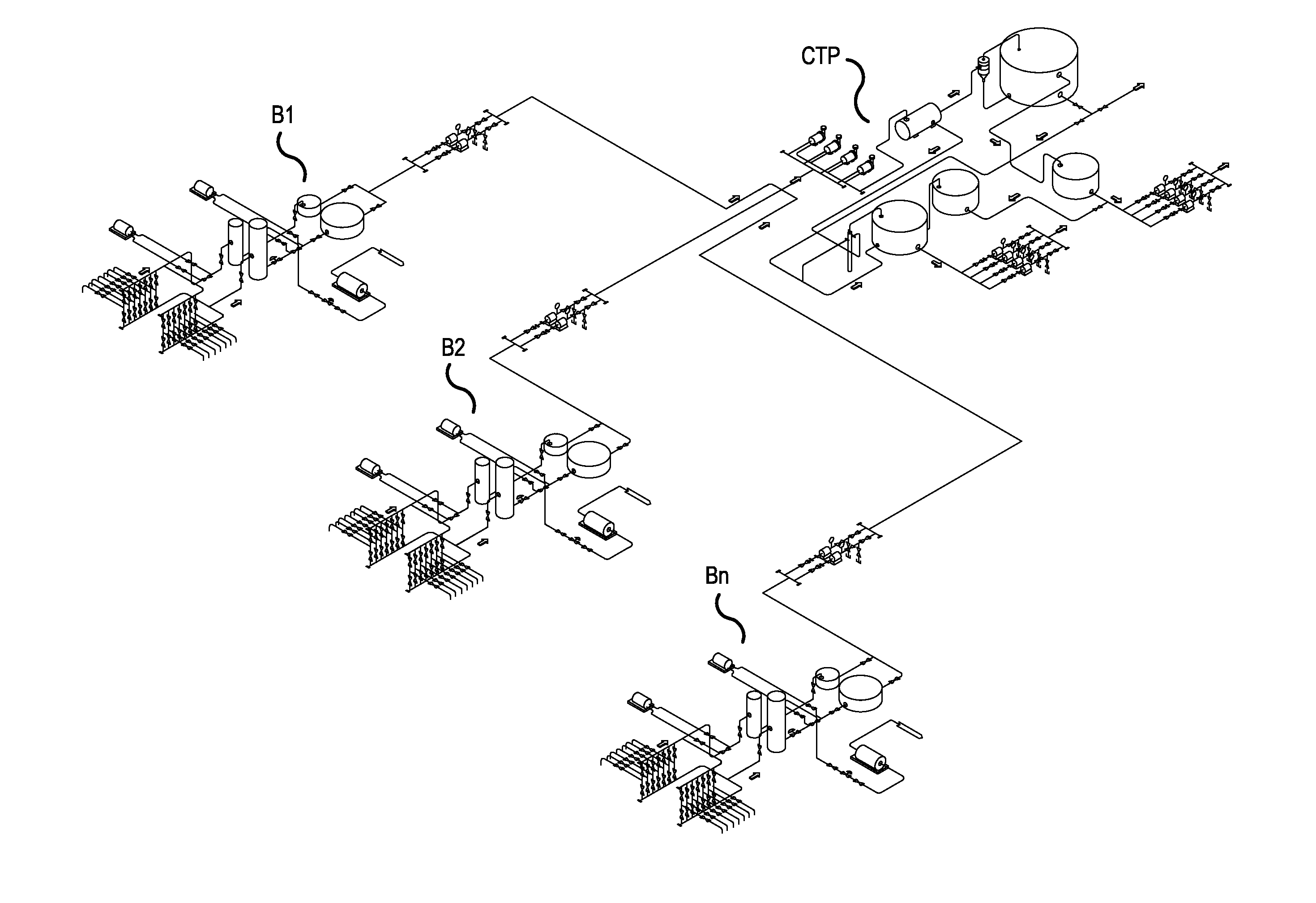

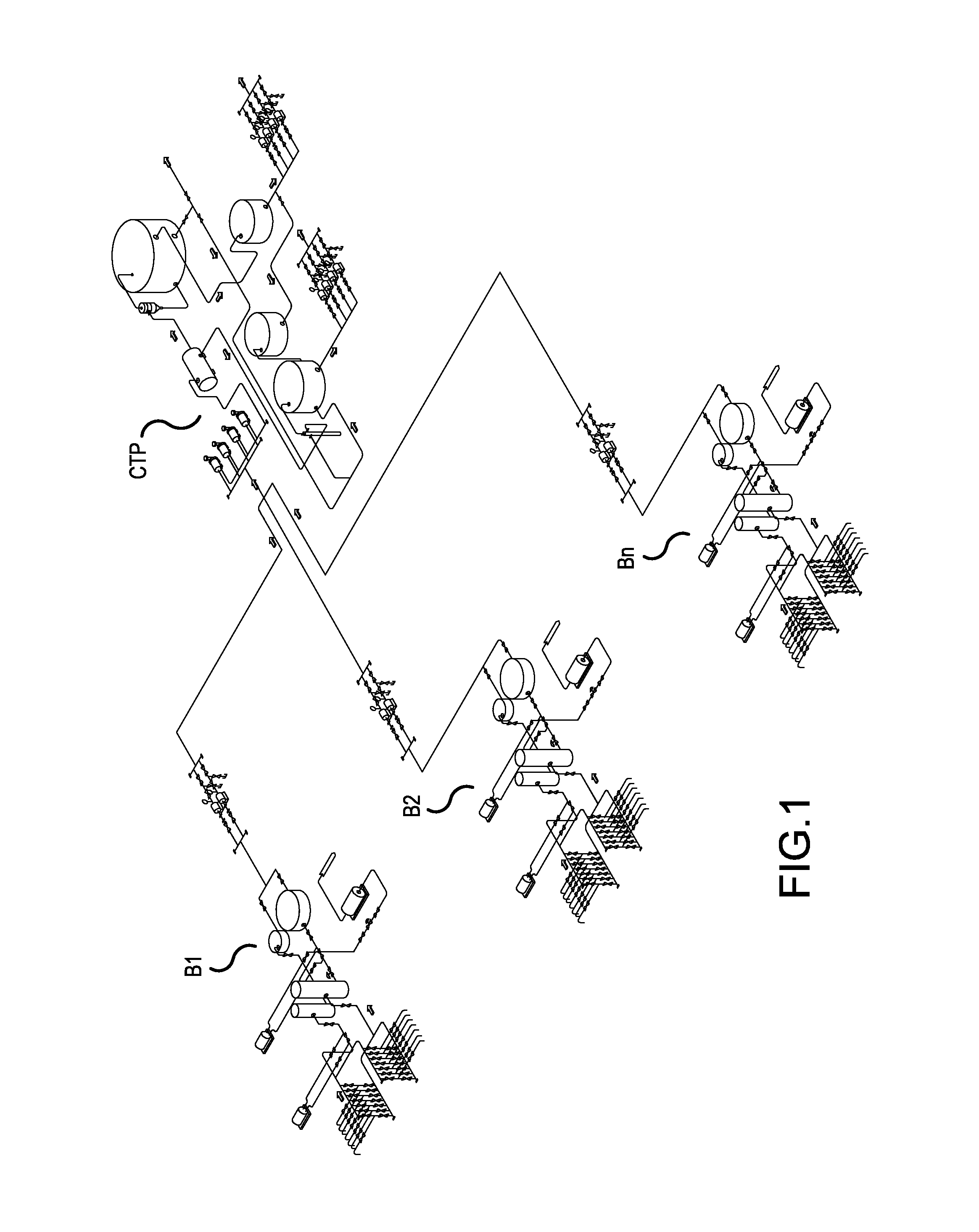

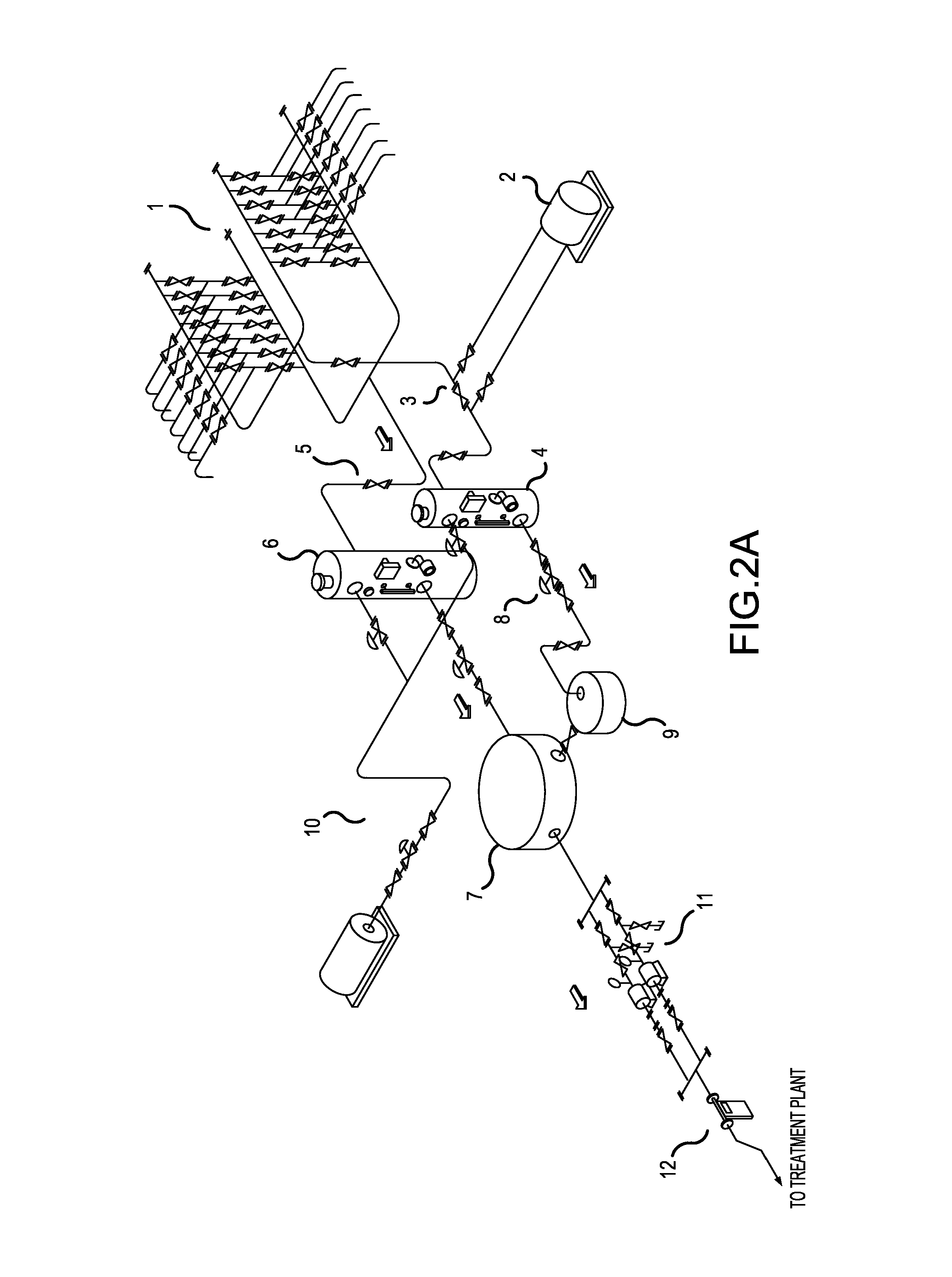

[0070]FIG. 2a shows a flowchart of a traditional battery in an oil production process. A manifold 1 is used for guiding a stream of produced fluid from a well, by means of one or more of various pump systems, like rod pumps, electrical submersible pumps (ESP), etc. Said manifold is connected to a control line 3, comprising a heater 2, a two-phase control separator 4, a control valve 8 and a control tank 9. The general installation line 5 comprises a two-phase general separator 6, a general tank 7, connected through a plurality of pumps 11 to a line leading to a treatment plant. The gross liquid production stored in the general tank 7 is pumped to the treatment plant by means of said pump assembly 11. The liquid is measured by a measuring bridge consisting of a mass flow meter and a water cut analyzer. Both the general separator 6 and the control separator 4 have an output for a gas line 10 which is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com