Refrigerant scroll compressor for motor vehicle air conditioning systems

a technology of refrigerant scroll compressor and air conditioning system, which is applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of only being able to control oil return and intermediate pressure, and the relative short axial installation length of the compressor, so as to improve the redundancy of lubricating the scroll, increase the functional reliability of the compressor, and stable sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The following detailed description and appended drawings describe and illustrate various exemplary embodiments of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner.

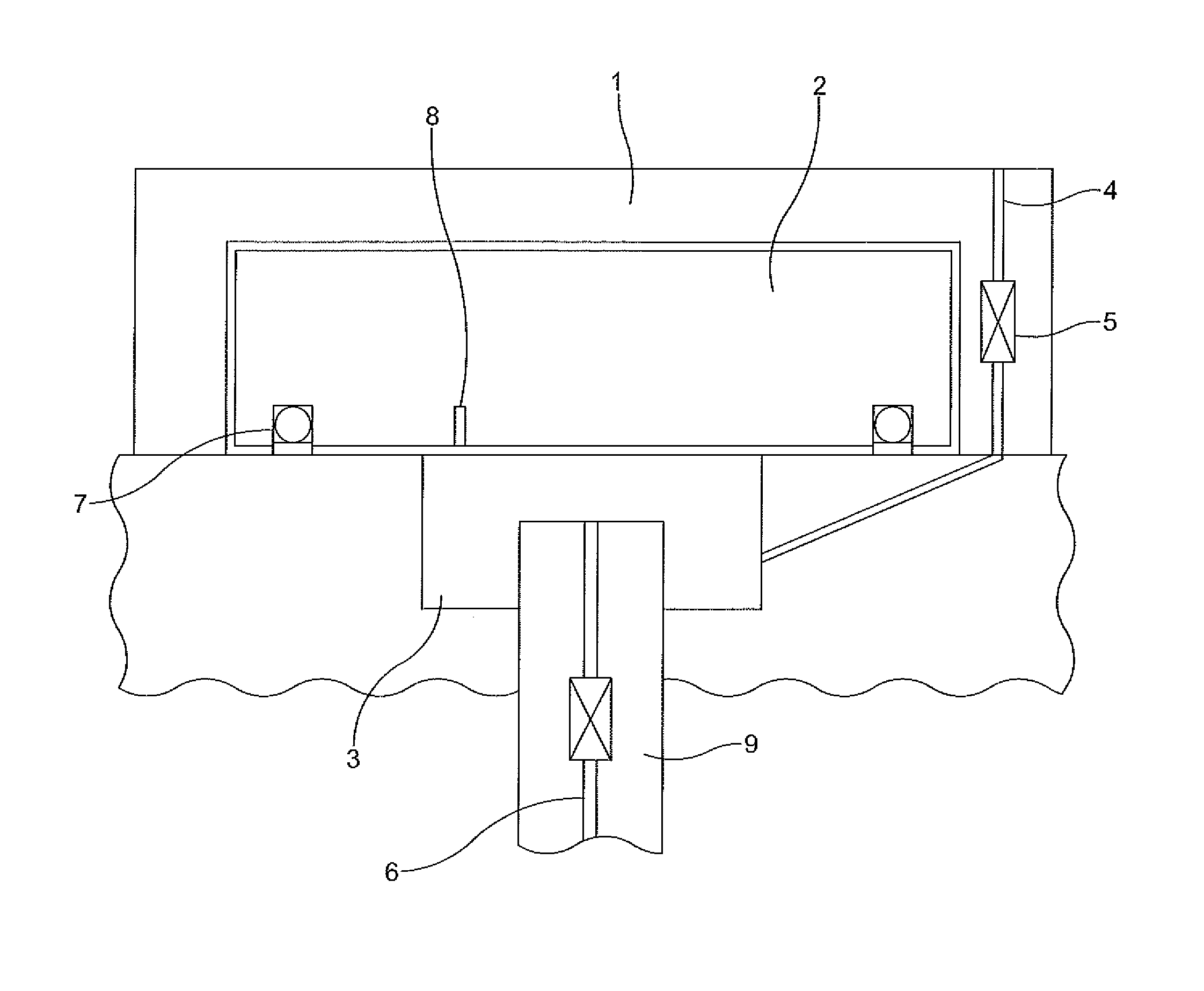

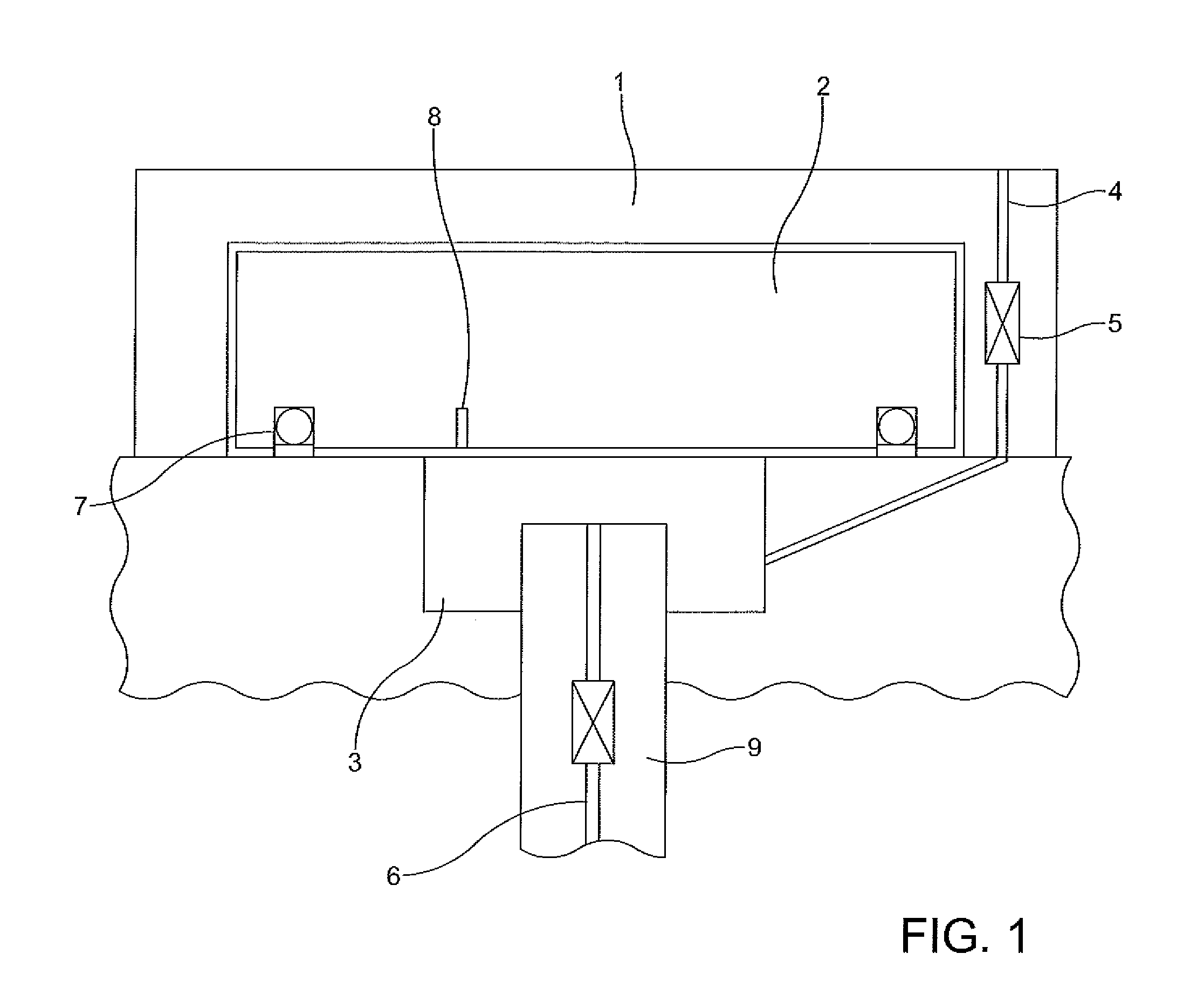

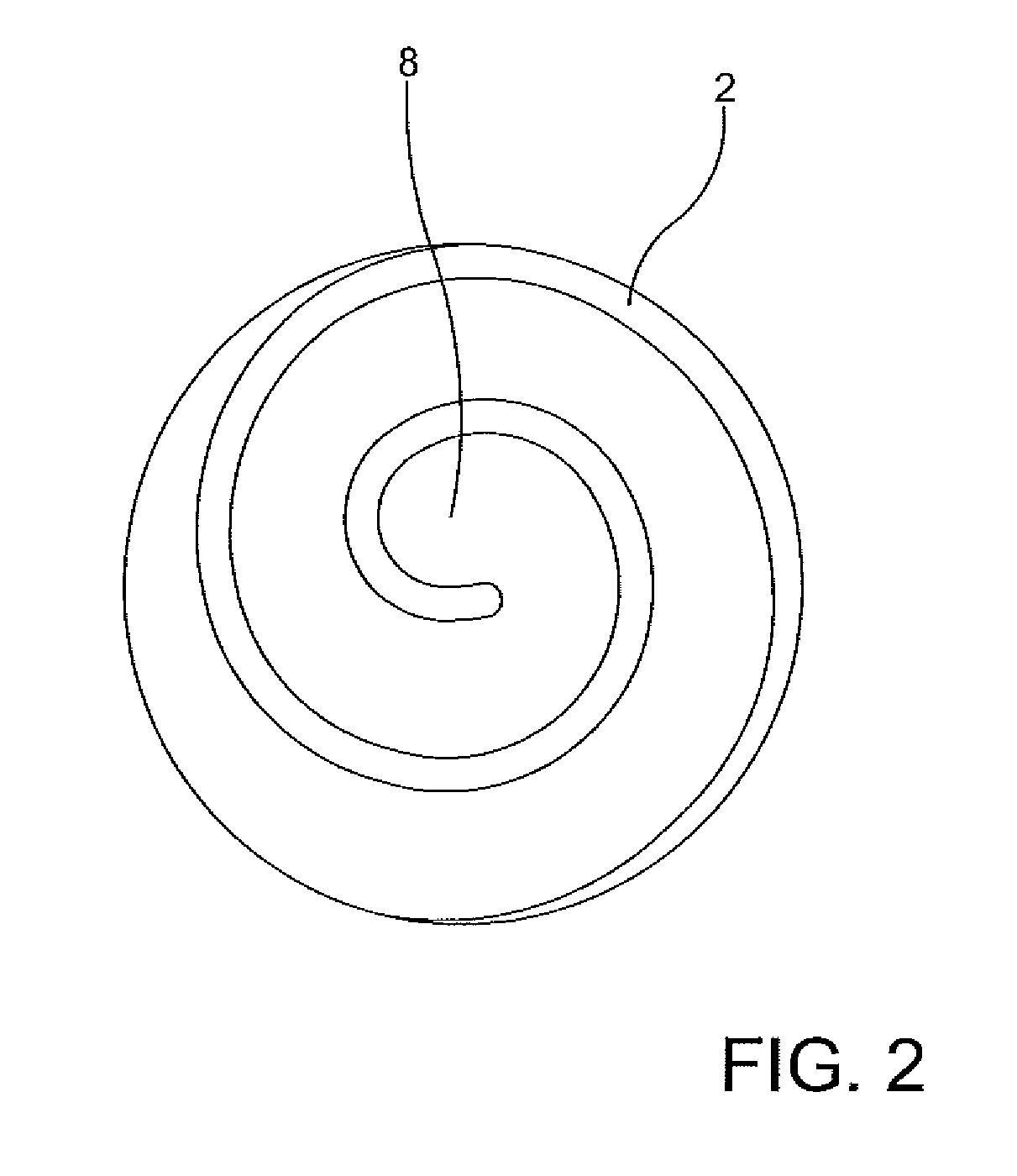

[0024]FIG. 1 shows a highly schematic cross-section of a refrigerant scroll compressor. For this purpose, and according to the functional principle, an orbiting scroll 2 is located in a fixed scroll 1. The orbiting scroll 2 moves in an oscillating manner in the fixed scroll 1 such that between the scrolls 1, 2, cavities are formed which decrease radially from the outside to the inside, in which the refrigerant gas is compressed from the outside to the inside and the compressed refrigerant gas inside is finally discharged axially into the high-pressure chamber. FIG. 1 illustrates an intermediate pressure chamber 3 below the scrolls 1, 2, in which the refrigerant gas exists at an inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com