An energy-saving hydraulic system for cranes

A hydraulic system and crane technology, which is applied in the field of energy-saving hydraulic systems for cranes, can solve the problems of large heat generation, poor control performance, and large energy loss in the system, and achieve the effects of stable operation, long service life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

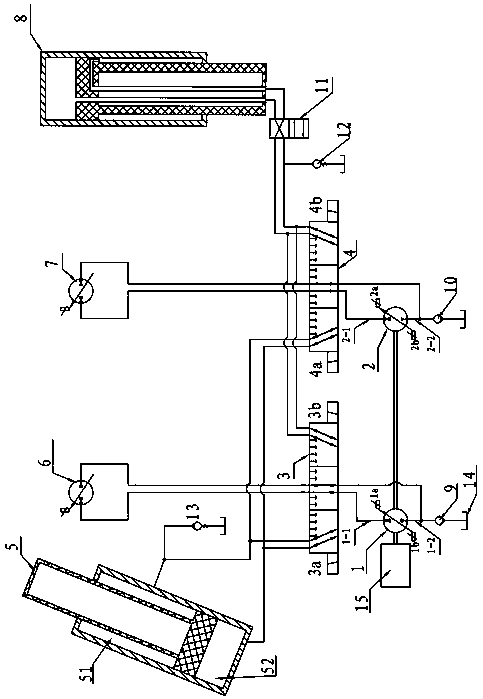

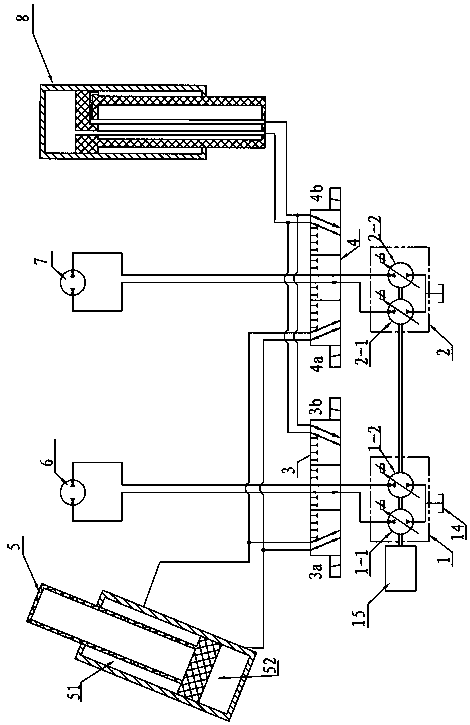

[0042] Example 1: See attached figure 2 ; An energy-saving hydraulic system for a crane, comprising an action device, a first control device and a second control device, the action device includes a luffing cylinder 5, a main winding motor 6, a secondary winding motor 7 and a telescopic cylinder 8, the The first control device includes two first pump motors 1 arranged in parallel, and the second control device includes two second pump motors 2 arranged in parallel, the first pump motor 1 and the second pump motor 2 Both are connected to the oil tank 14. The first pump motor 1 is connected to the luffing cylinder 5, the main winding motor 6, and the telescopic cylinder 8 through the first switching valve 3. The second pump motor 2 is switched through the second switch The valve 4 is connected with the luffing oil cylinder 5, the auxiliary winding motor 7, and the telescopic oil cylinder 8. In the present invention, two first pump motors and two second pump motors are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com