Method for manually regenerating particulate filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

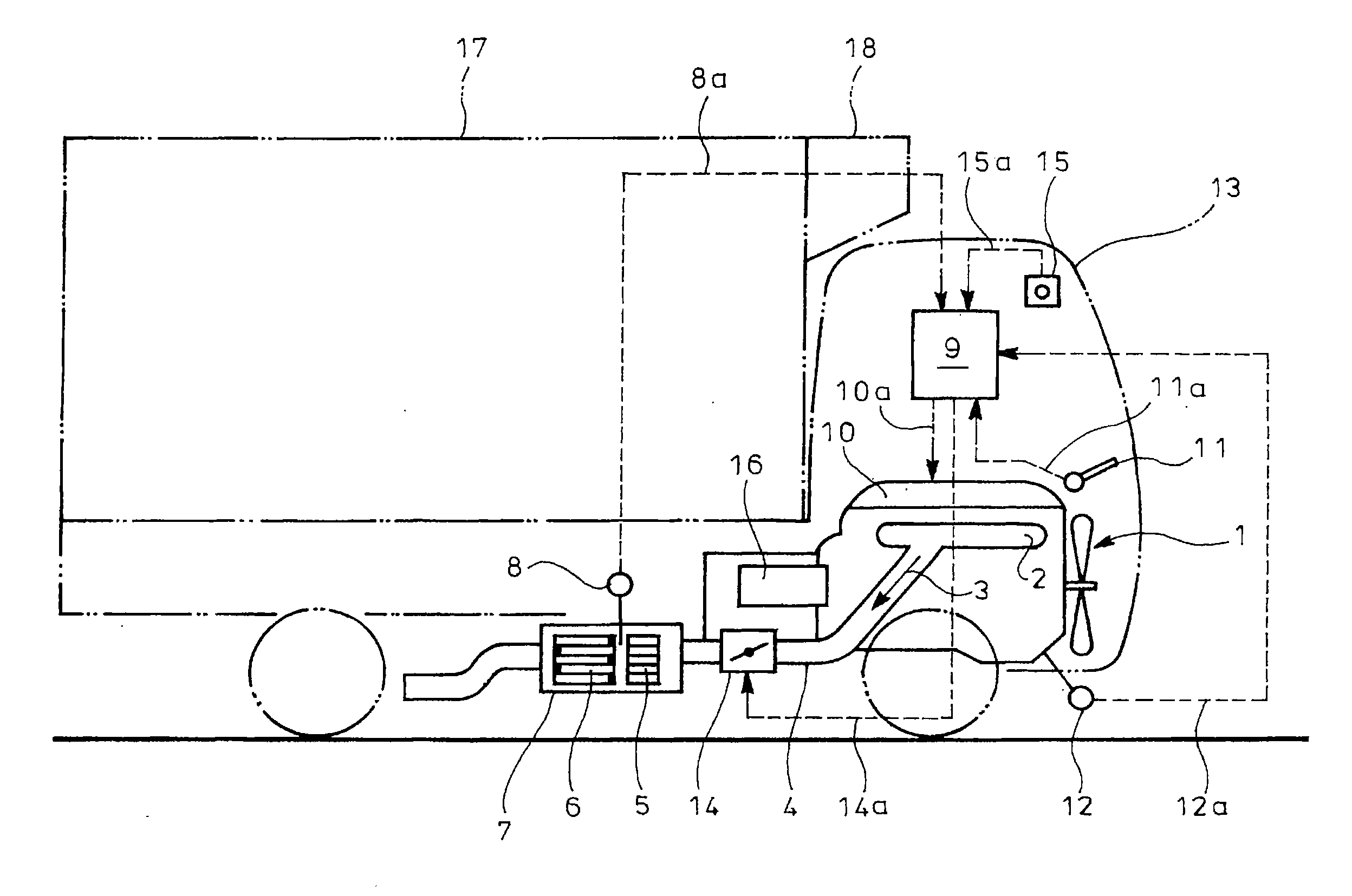

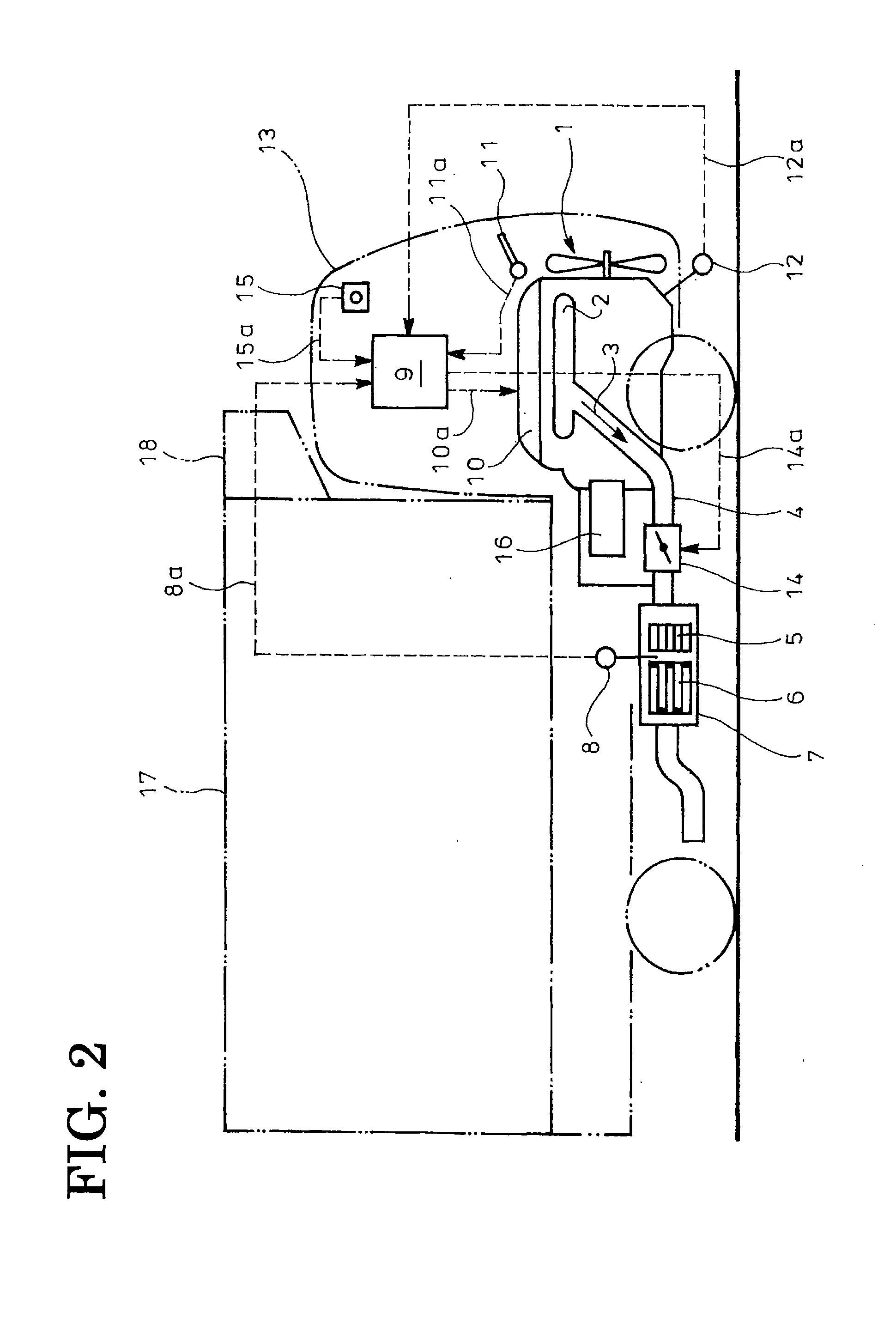

[0028]An embodiment of the invention will be described in conjunction with the drawings.

[0029]FIG. 2 shows the embodiment of the invention. Exemplarily illustrated is a refrigerator van as objective vehicle with a refrigeration compressor as auxiliary machine. A catalyst regenerative particulate filter 6 with an oxidation catalyst 5 preceding the same is encased by a filter case 7 and incorporated in an exhaust pipe 4 through which exhaust gas 3 discharged from a diesel engine 1 (engine) of the van via an exhaust manifold 2 flows.

[0030]The filter case 7 is provided with a temperature sensor 8 which detect a temperature of the exhaust gas 3 at between the oxidation catalyst 5 and the particulate filter 6, a temperature signal 8a from the sensor 8 being inputted to a controller 9 which constitutes an engine controlling computer (ECU: Electronic Control Unit).

[0031]The controller 9 is responsible also for control of fuel injection. Specifically, on the basis of an accelerator opening d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com