Gas turbine engine fan casing having a flange for fastening pieces of equipment

a technology for gas turbine engines and fan casings, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problem that the flange of the fan casing is only a fraction of the thickness of the flange, and the flange is made through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

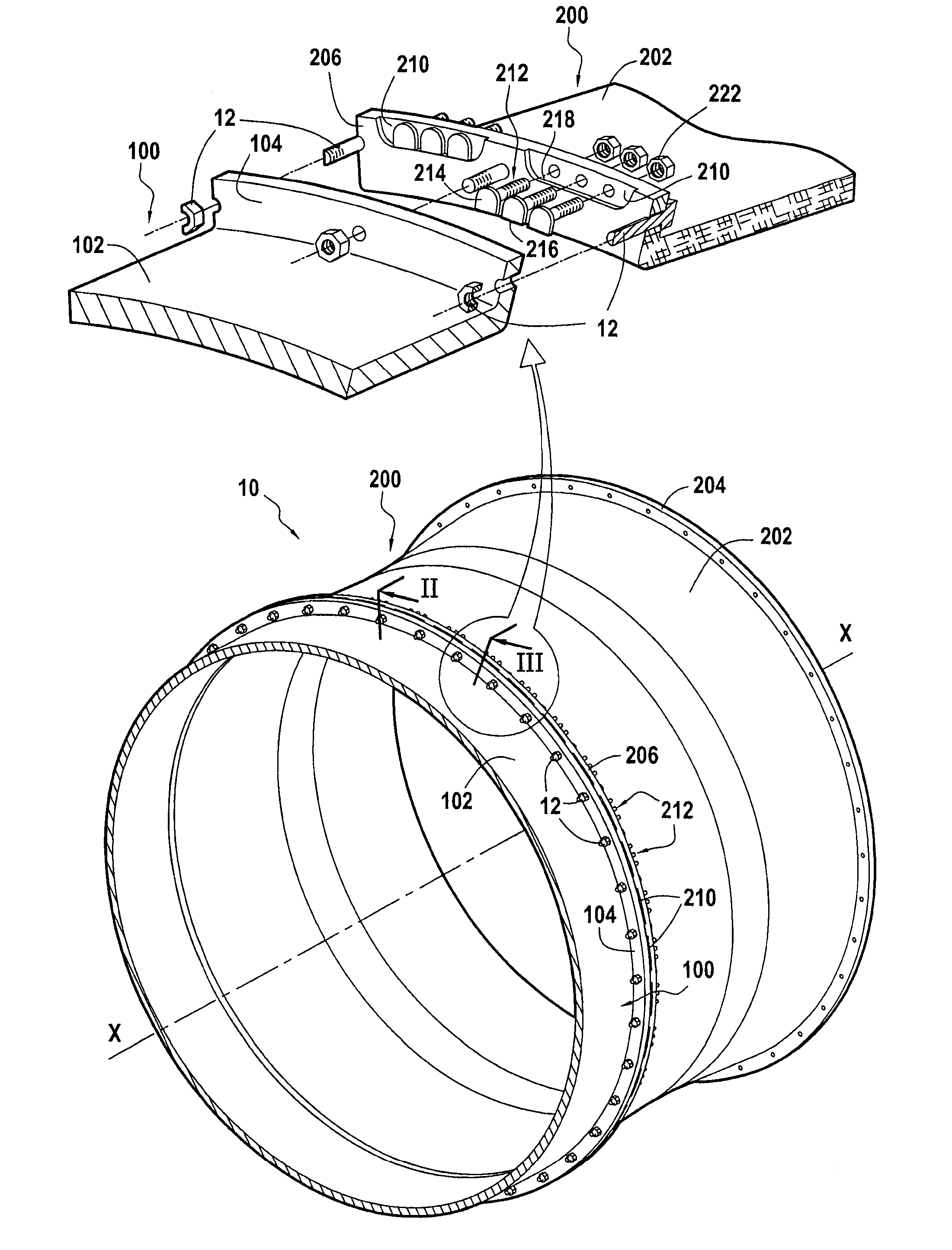

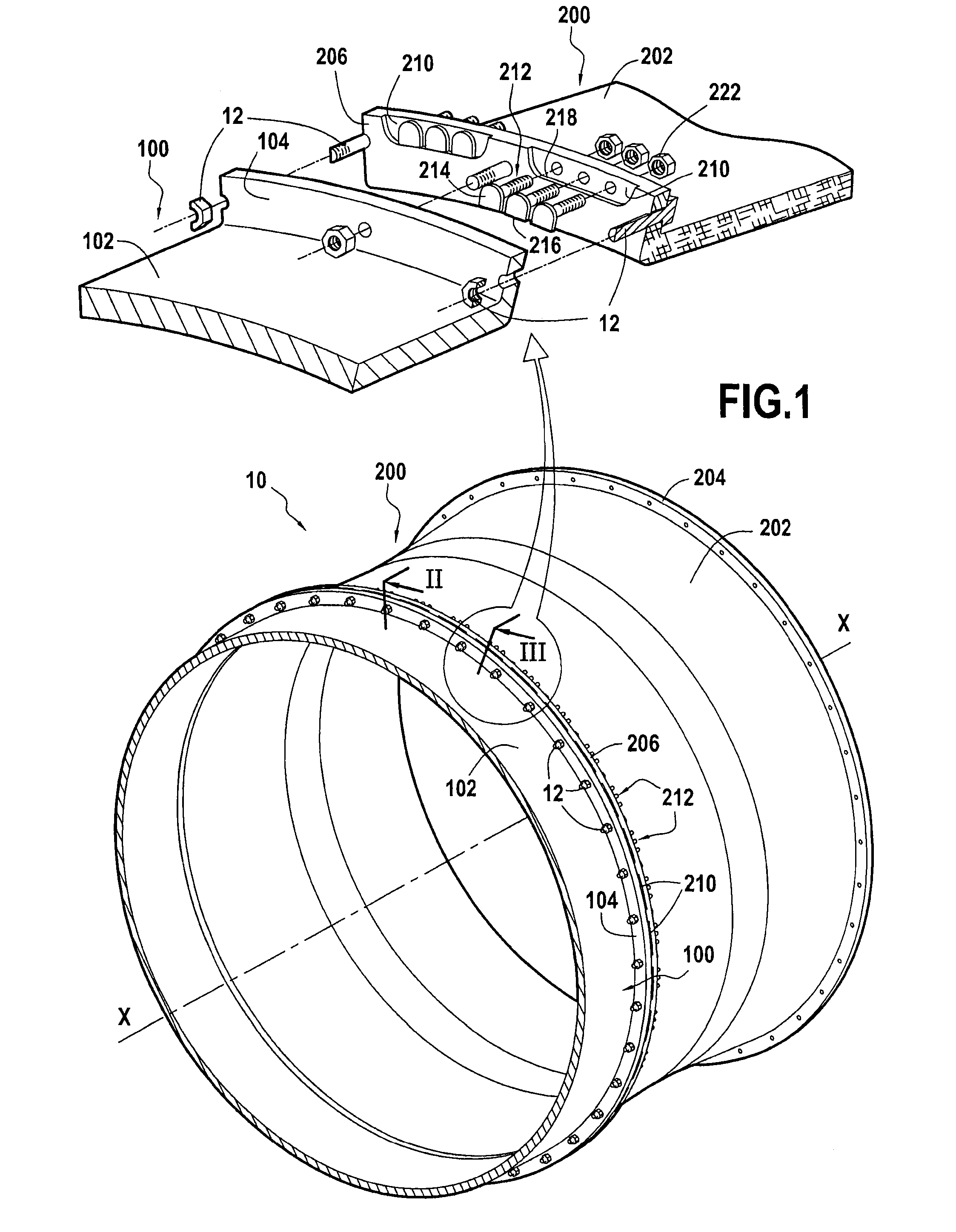

[0021]FIG. 1 shows a casing 10 within which it is possible to house a gas turbine aeroengine (not shown).

[0022]The casing 10 comprises a plurality of elements: namely in particular an air inlet sleeve 100 arranged at the inlet of the engine; and a fan casing 200 arranged downstream from the air inlet sleeve (“downstream” in the flow direction of the stream of gas passing through the engine). Each of these elements comprises a substantially cylindrical portion, respectively referenced 102 or 202, which portion is centered on a longitudinal axis X-X of the engine.

[0023]The inside surface of the cylindrical portion 102 of the air inlet sleeve 100 defines the air inlet passage into the engine. The inside surface of the cylindrical portion 202 of the fan casing serves to surround the tips of the fan blades of the engine and it incorporates or supports a retention shield (not shown).

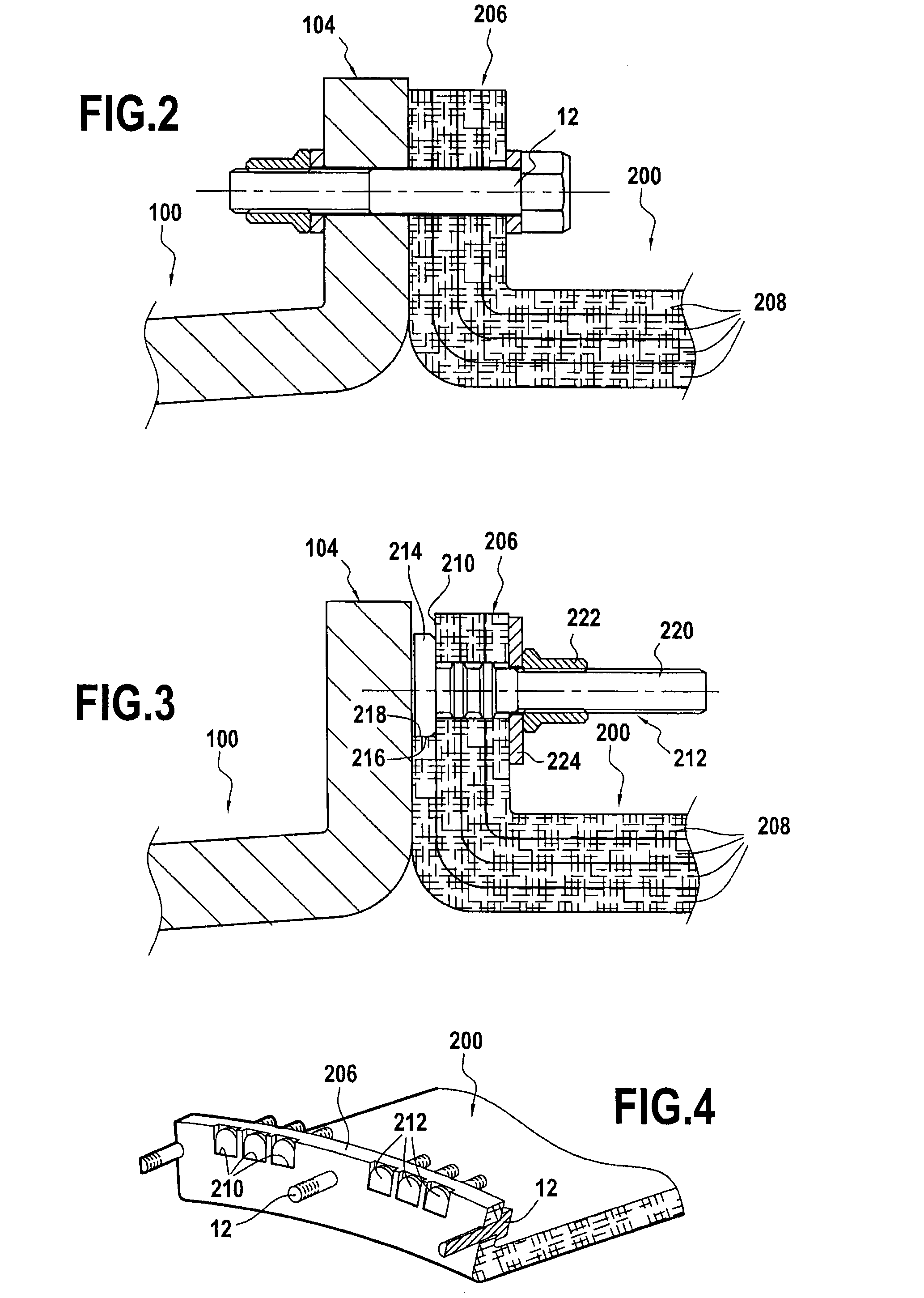

[0024]At its downstream end, the cylindrical portion 102 of the inlet sleeve 100 is terminated by an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com