Method for production of polymer containing fibres

a technology of polymer fibres and fibres, which is applied in the field of polymer fibre formation methods, can solve the problems of difficult to find a commercially viable process for mass-producing spider silk, the requirements of methods are usually too harsh for the involvement of biological materials such as proteins or cells, and the combination of all these properties has proved difficult, so as to increase the elongational viscosity of the solution. , the effect of increasing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Principle of the Drawing Process

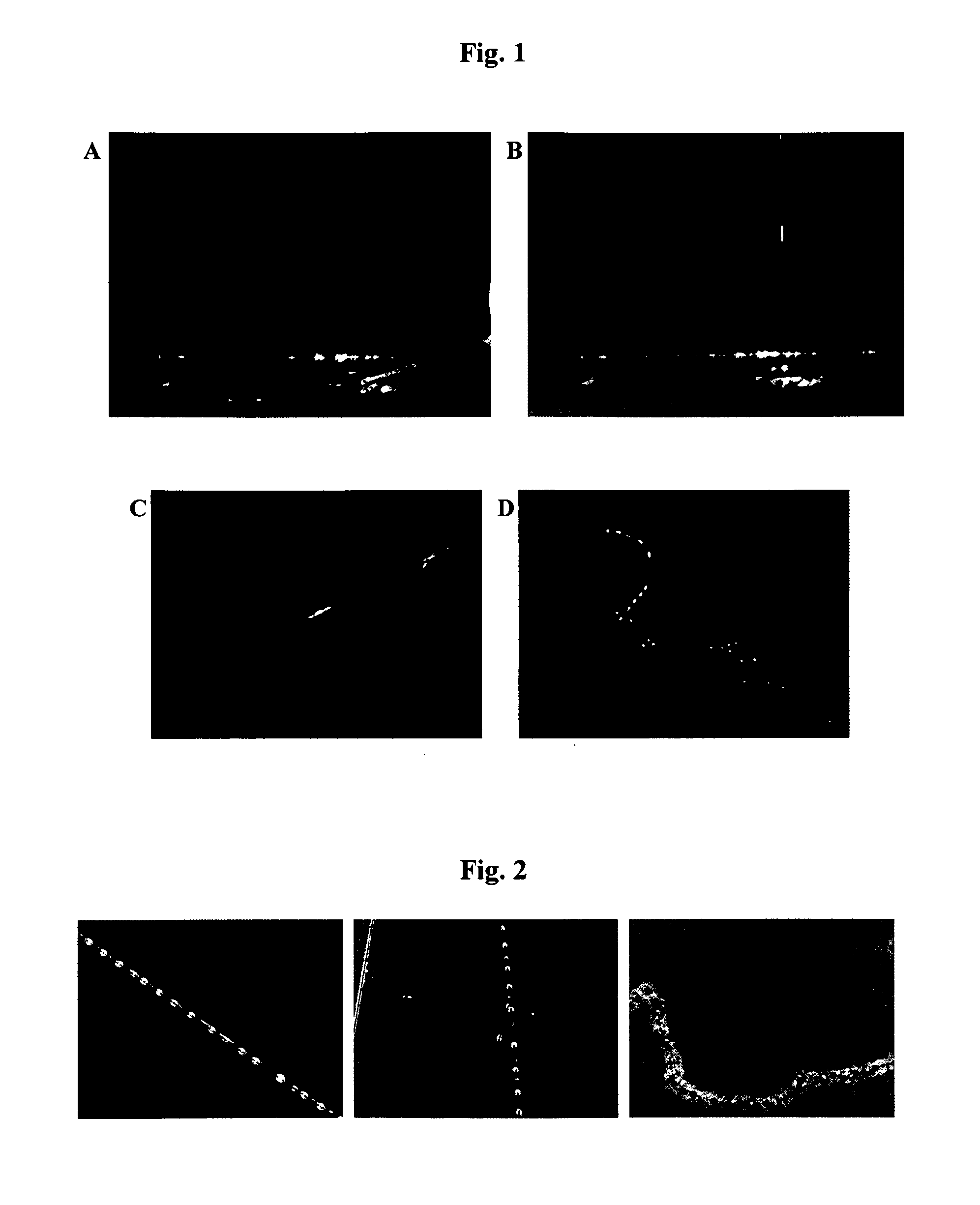

[0198]FIG. 1A shows an aliquot of spinning solution consisting of C16 as the constituent polymer, PAA as the elongational viscosity enhancing polymer, and water as the solvent on a glass microscopy slide, in contact with a plain glass needle as the drawing tool. Pulling the needle, which is in contact with the spinning solution, away from the solution produces a thin fluid filament. This filament, if drawn quickly enough, exists long enough to allow evaporation of the solvent water and the formation of a thin and light fibre (FIG. 1B). The fibres contain protein, which can be shown by IR spectroscopy and by fluorescence microscopy when labelled protein is used.

example 2

Fibres from a Low Concentration Spider Silk Protein

[0199]100 μl spinning solution (10 mg / ml FITC-C16, 1.0 wt % / vol PAA) were placed on a glass microscopy slide. A plain glass needle (5 cm long and 1 mm in diameter) was brought into contact with the spinning solution and then pulled away from the microscopy slide by hand at variable speeds. This process resulted in a fibre being pulled from the spinning solution, the quality of the fibre depended on the speed used. At or above a pulling speed of 10 cm / s, the fibres appeared smooth and homogenous (FIG. 1 C). When pulling at speeds below the threshold, droplets of liquid were still coating the fluid filament and remained after fibre deposition on a clean glass microscopy slide (FIG. 1D). Good fibre formation occurred at a pulling speed of 10 cm / s and above.

example 3

Fibres Pulled by a Falling Steel Bead

[0200]100 μl spinning solution (10 mg / ml C16, 1.0 wt % / vol PAA) were placed next to the rim of glass microscopy slide. A steel bead of 1 mm diameter was placed between rim and a spinning solution, touching the spinning solution. While the microscopy slide was being held by hand, it was tilted slightly to cause the bead falling off the rim. Surprisingly, the falling bead pulled a fibre from the spinning solution not unlike the needle from Example 1. The process of the bead falling and producing a fibre can be compared to a falling spider producing a fibre, although obviously the reservoir of spinning dope is at different ends of the fibre.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com