Polyurethane composition for cmp pads and method of manufacturing same

a technology of polyurethane composition and cmp pads, which is applied in the direction of lapping machines, grinding devices, other chemical processes, etc., can solve the problems of reducing the stiffness of the pad, increasing the dishing, and reducing the planarization efficiency, so as to simplify the overall fabrication process and reduce the frothing time , the effect of sacrificing foaming characteristics and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

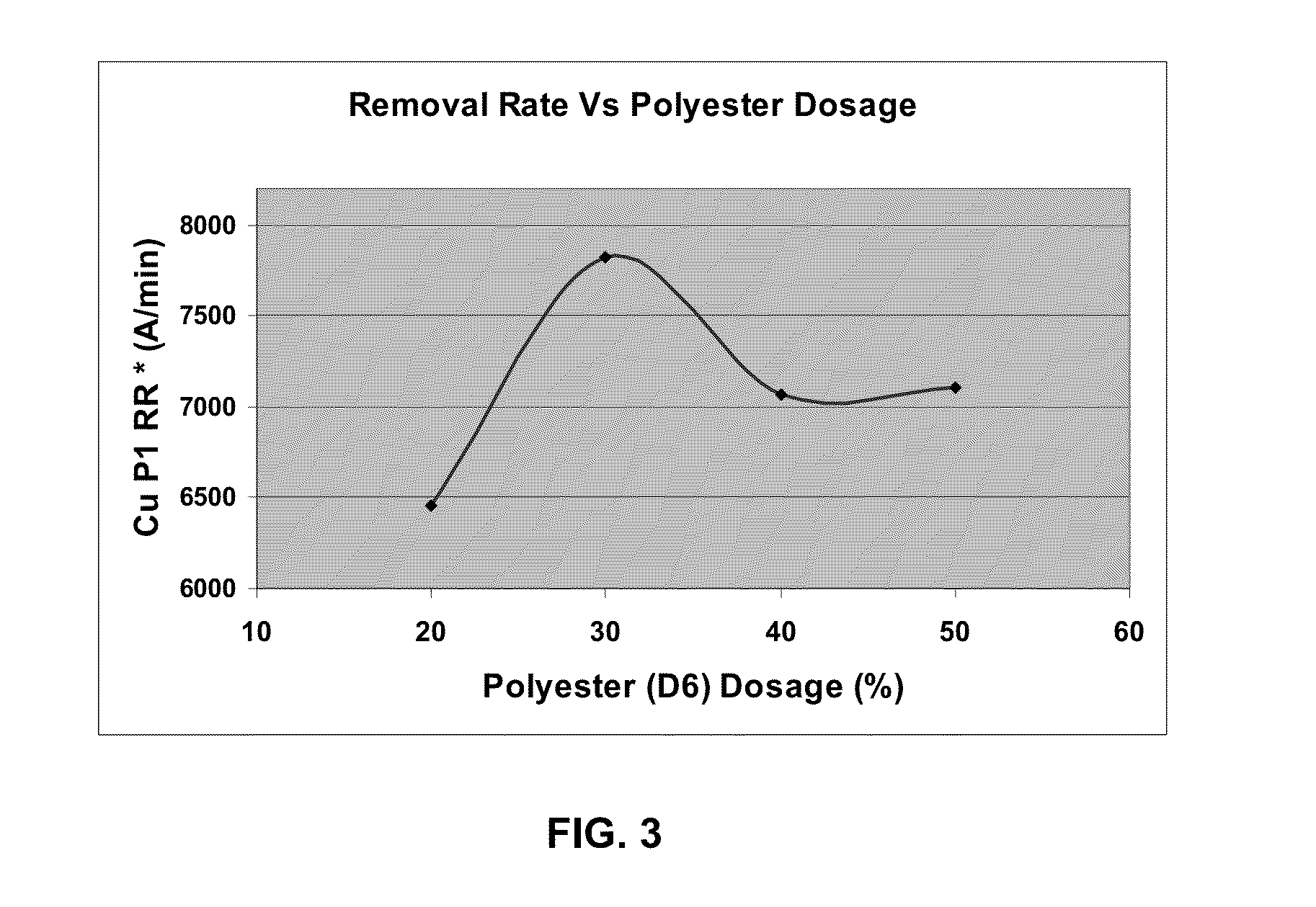

[0081]Sixty thousand (60,000) grams of total prepolymer was measure out. Of this, forty two thousand (42,000) grams of TDI-terminated polyether prepolymer manufactured by Chemtura Corporation and sold under the tradename Adiprene LF 750D was measured, and supplied to the processing tank equipped with variable heating temperature and agitation speed. Separately, (18,000) grams of TDI-terminated polyester prepolymer manufactured by Air Products and Chemicals, Inc. and sold under the name Versathane D-6 was measured and added to the processing tank containing the 42,000 grams of polyether prepolymer.

[0082]Twelve hundred (1,200) grams of silicone surfactant sold as Niax L-5340 by Momentives, Inc. was added to the process tank, and the mixture was agitated with a simple impeller to create a moderate vortex. The process tank is heated to 150° F. under an nitrogen atmosphere.

[0083]In a separate curative process tank, twenty thousand (20,000) grams of diamine curative manufactured by Albema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| frothing temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com