Dope for spinning lyocell, method for preparing lyocell filament fiber, and method for preparing lyocell staple fiber using the same

a technology of lyocell and filament fiber, which is applied in the field of lyocell filament fiber and lyocell staple fiber preparation, can solve the problems of easy shrunken and wrinkled rayon fiber, complicated manufacturing process, environmental problems in operation or environmental pollution, etc., and achieves low orientation degree and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

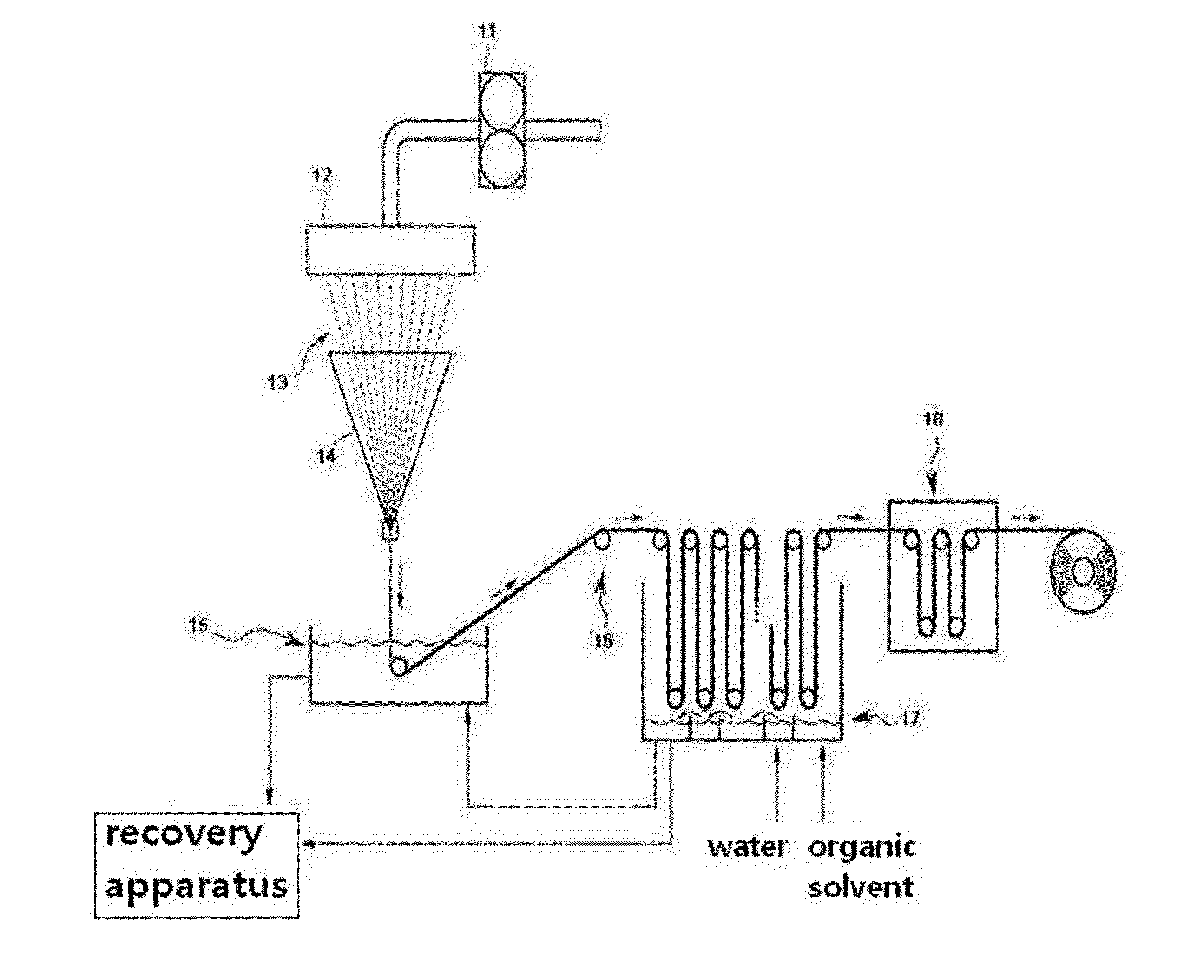

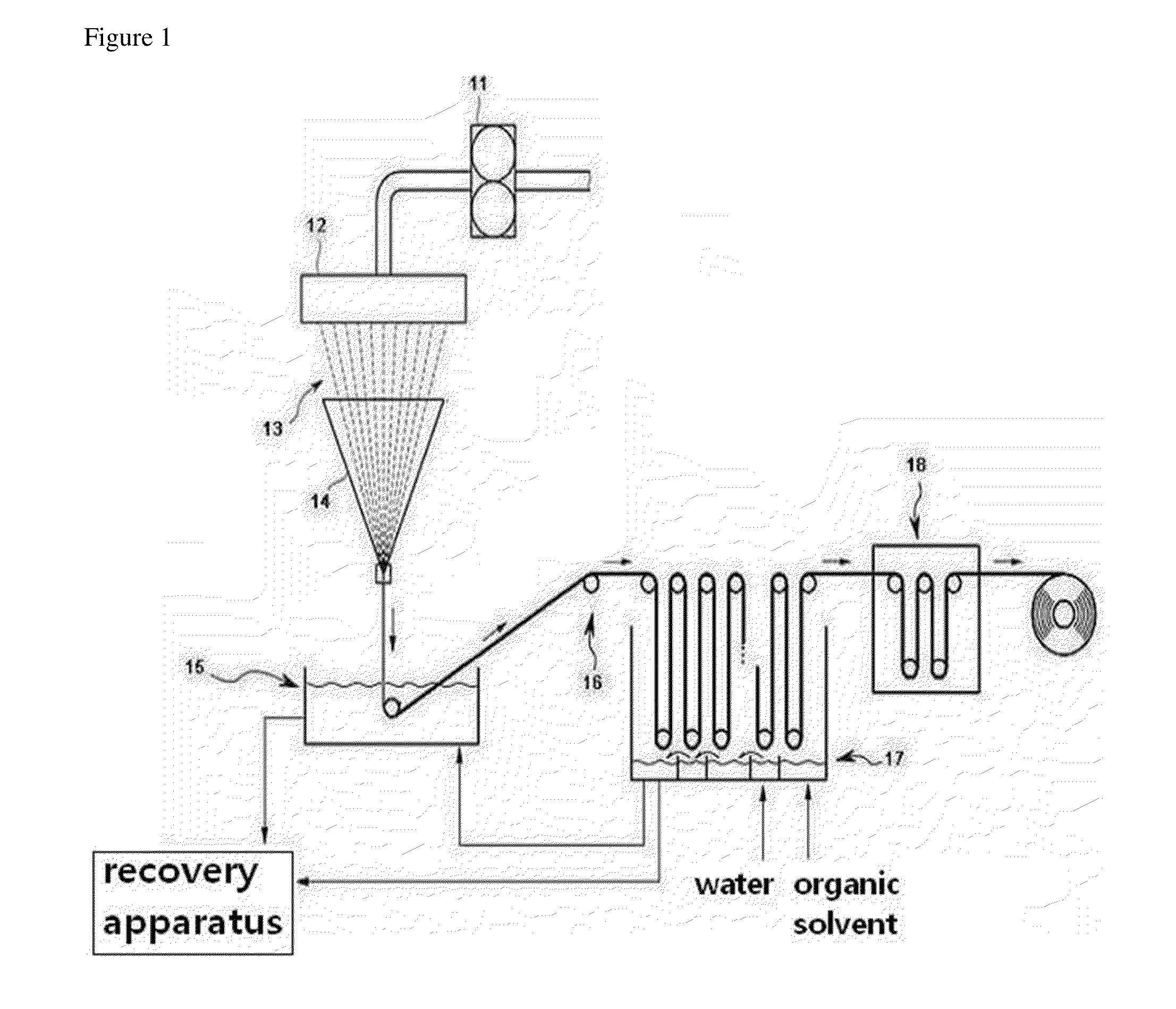

Manufacture of Lyocell Filament Fiber from Cotton Linter Pulp

[0069]Cotton linter pulp with a polymerization degree (DP) of 1200 (supplied from Korea Minting and Security Printing Corporation) was introduced into a pulverizer equipped with a 100 mesh filter to prepare pulp powder having a diameter of 1700 μm or less.

[0070]The pulp powder was swollen in a 50 wt % NMMO aqueous solution. The NMMO aqueous solution includes 6 wt % of the pulp, and an antioxidant was added in the content of 0.01 wt % to the cotton linter pulp.

[0071]The swollen pulp slurry was injected into a kneader maintaining an internal temperature of 90° C. and absolute pressure of 50 mmHg with a rotary valve pump at a speed of 16 kg / hour, and completely dissolved while removing extra moisture so that a 50 wt % of NMMO aqueous solution may become a 89 wt % NMMO aqueous solution, and then spinning dope was discharged through a discharge screw.

[0072]The spinning dope was controlled so that total fineness of the ...

example 2

Manufacture of Lyocell Filament Fiber from Cotton Linter Pulp

[0075]Lyocell multifilament yarn was obtained by the same method as Example 1, except using cotton linter pulp of a polymerization degree (DP) of 800.

example 3

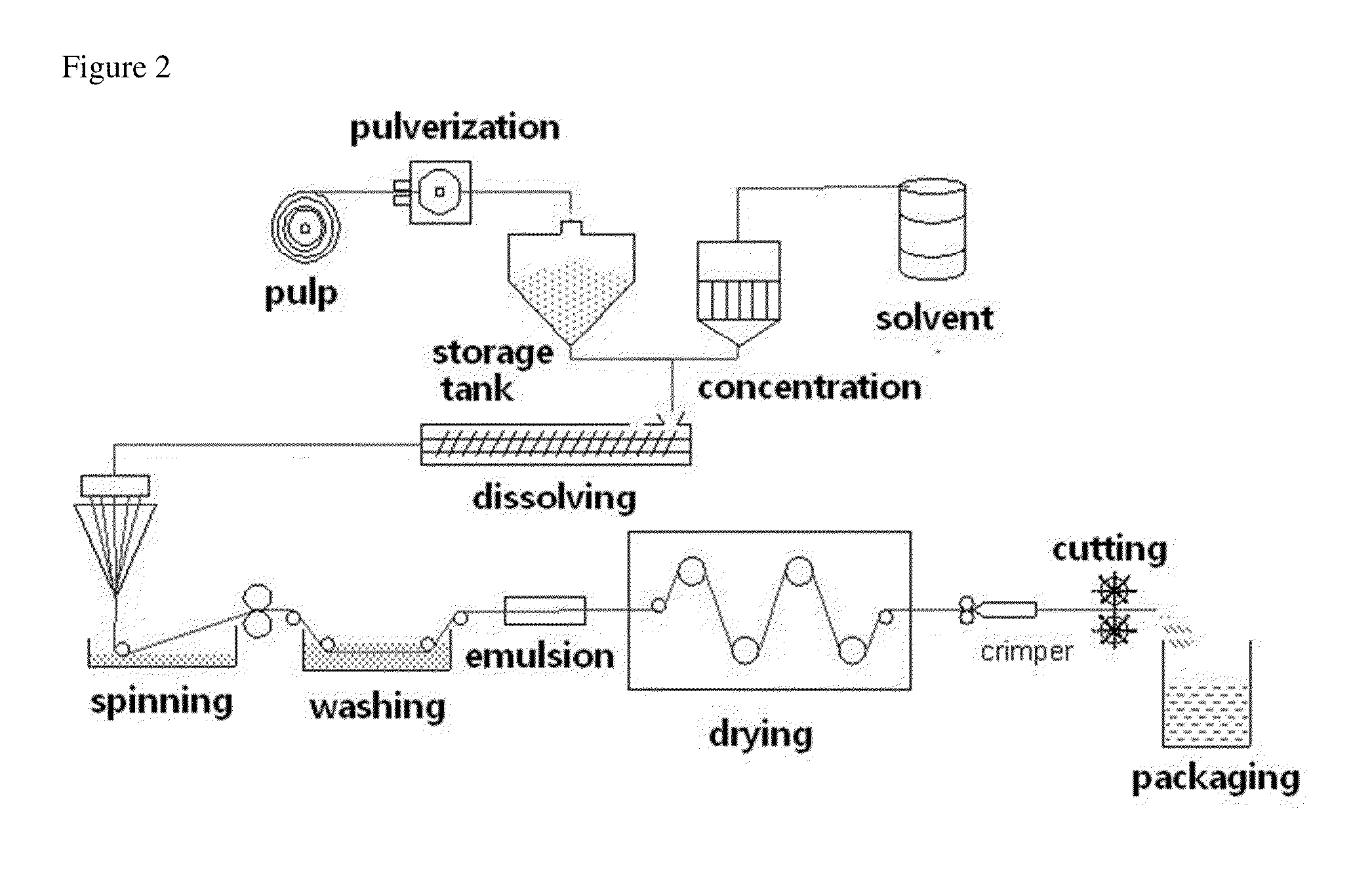

Manufacture of Staple Fiber from Cotton Linter Pulp

[0076]Cotton linter pulp (supplied from Korea Minting and Security Printing Corporation) of a polymerization degree (DP) of 1200 was introduced into a pulverizer equipped with a 100 mesh filter to prepare pulp powder having a diameter of 1700 μm or less.

[0077]The pulp powder was swollen in a 50 wt % NMMO aqueous solution. The NMMO aqueous solution included 6 wt % of the pulp, and an antioxidant was added in the content of 0.01 wt % to the cotton linter pulp.

[0078]The swollen pulp slurry was injected into a kneader maintaining an internal temperature of 90° C. and absolute pressure of 50 mmHg with a rotary valve pump at a speed of 16 kg / hour, and completely dissolved while removing extra moisture so that a 50 wt % NMMO aqueous solution may become an 89 wt % NMMO aqueous solution, and then spinning dope was discharged through a discharge screw.

[0079]The spinning dope was controlled so that total fineness of the final filament may beco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com