Process for integrated production of ethanol and seaweed sap from kappaphycus alverezii

a technology of kappaphycus alvarezii and ethanol, which is applied in the direction of biofuels, fermentation, etc., can solve the problems of residual material, increase in food price, and agricultural production dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

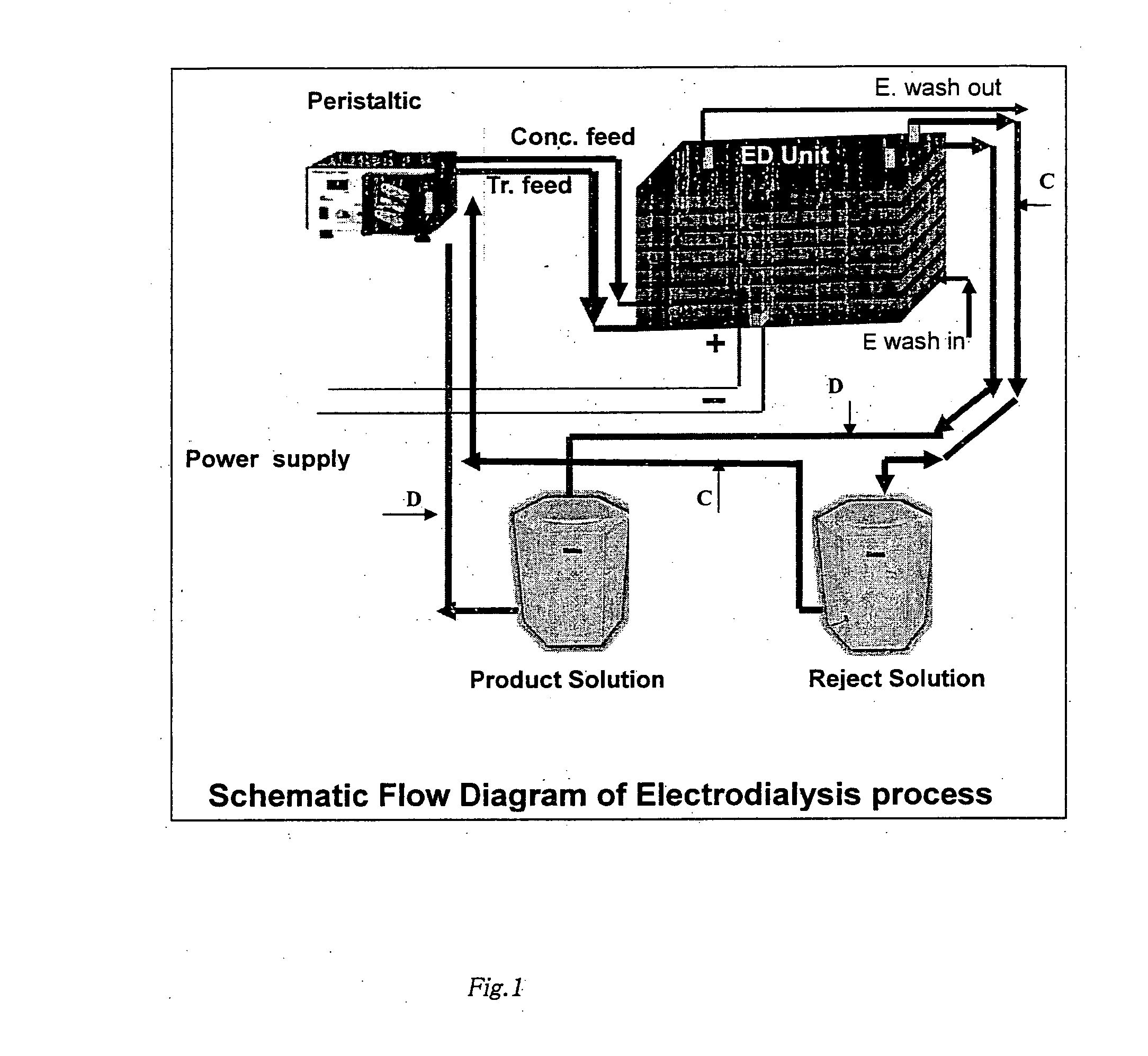

Image

Examples

example 1

[0099]After recovering liquid sap from fresh Kappaphycus, the residual granules are washed and dried. The known weight of dry granules was saccharified with dilute sulfuric acid at elevated temperature for specified period. Total sugar and reducing sugars are measured in the hydrolysate by phenol-sulfuric acid method and Nelson's method respectively. The conditions used for saccharification and sugar generated during saccharification are detailed in Table 1 & 2.

TABLE 1CarrageenanSulfuricTemperatureTotalReducinggranules (g)acid (%) / vol(° C.) and timeSugar (%)sugar (%)100.3 / 200 ml121° C. / 15 min2.511.020.5 / 200 ml121° C. / 15 min2.961.210.7 / 200 ml121° C. / 15 min3.341.37100.7 / 200 ml121° C. / 5 min 2.330.95121° C. / 10 min2.941.20121° C. / 15 min3.281.34100.7 / 200 ml37° C. / 1 day 1.320.31 37° C. / 2 days1.420.5860° C. / 1 day 2.661.09 60° C. / 2 days3.381.38100.5 / 200 ml100° C. / 1 h 2.120.61

TABLE 2CarrageenanSulfuricTemperatureReducinggranules (g)acid (%) / vol(° C.) / timesugar (%)30.5 / 100 ml 80 / 1 h0.5531.0 / ...

example 2

[0101]To achieve maximum reducing sugar concentration in the hydrolysate, 20 g of washed and dried Kappaphycus alvarezii granules are extracted in 1000 ml of 0.5% sulfuric acid. The hydrolysate is flittered and same amount of new, fresh granule is added to the filtrate of earlier cycle and hydrolysed under similar conditions. Similarly, the cycles are repeated thrice. The sugar concentration obtained during each cycle is given in Table 3.

TABLE 3Volume ofWt ofacid / hydro-Time (h) / Vol (ml) ofCyclegranuleslysate andtemperaturerecoveredReducingNo.(g)strength(° C.)hydrolysatesugar (%)1201000 ml / 0.5%1 / 1009250.403220925 ml1 / 1008750.910320875 ml1 / 1008401.6

[0102]Here 13.44 g of total reducing sugar is recovered out of 60 g of granules which is equivalent to 48 g of carrageenan (after removal of moisture and fiber content (20%). Thus 28% of carrageenan is converted to simple sugar.

[0103]To increase the efficiency of hydrolysis and sugar concentration, higher acid concentration and repeated ext...

example 3

[0104]To achieve maximum reducing sugar concentration in the hydrolysate, 50 g of fresh granules is extracted in 1000 ml of 2.5% sulfuric acid and fresh granules is added to the filtrate of earlier cycle and hydrolysed under similar conditions. Similarly, the cycles are repeated thrice. The sugar concentration obtained during each cycle is given in Table 4.

TABLE 4Volume ofWt ofacid / hydro-Time (h) / Vol (ml) ofCyclegranuleslysate andtemperaturerecoveredReducingNo.(g)strength(° C.)hydrolysatesugar (%)1501000 ml / 2.5%1 / 1009751.5250975 ml1 / 1009003.3350900 ml1 / 1008505.2

[0105]Here 44.2 g of total reducing sugar is recovered out of 150 g of granules which is equivalent to 120 g of carrageenan (after removal of moisture and fiber content (20%). Thus 36.8% of carrageenan is converted to simple sugar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com