Instrument for positioning a cup component of an orthopaedic joint prosthesis

a technology for orthopaedic joints and instruments, applied in the field of instruments for positioning the cup component of orthopaedic joints, can solve problems such as affecting the bearing properties of orthopaedic joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

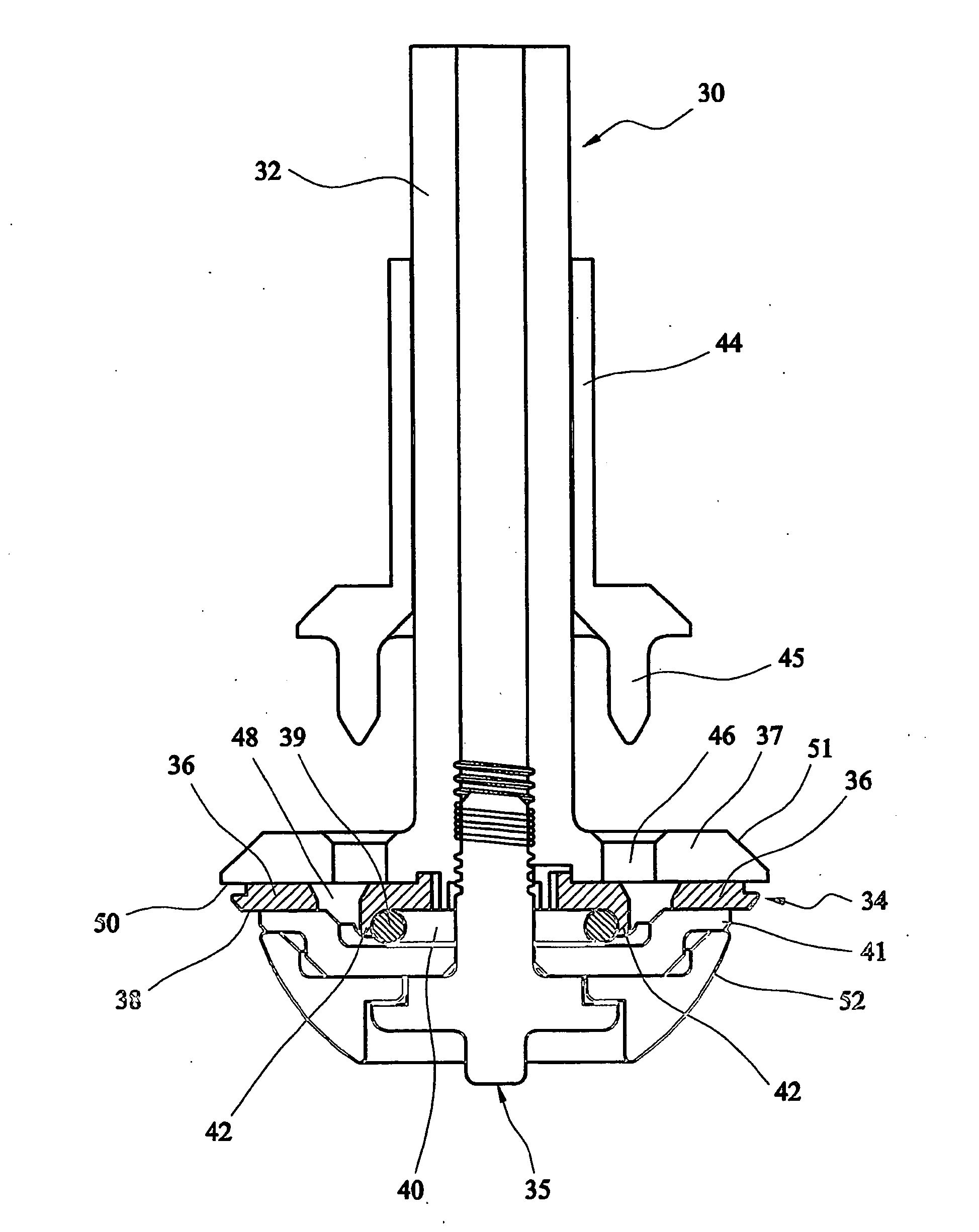

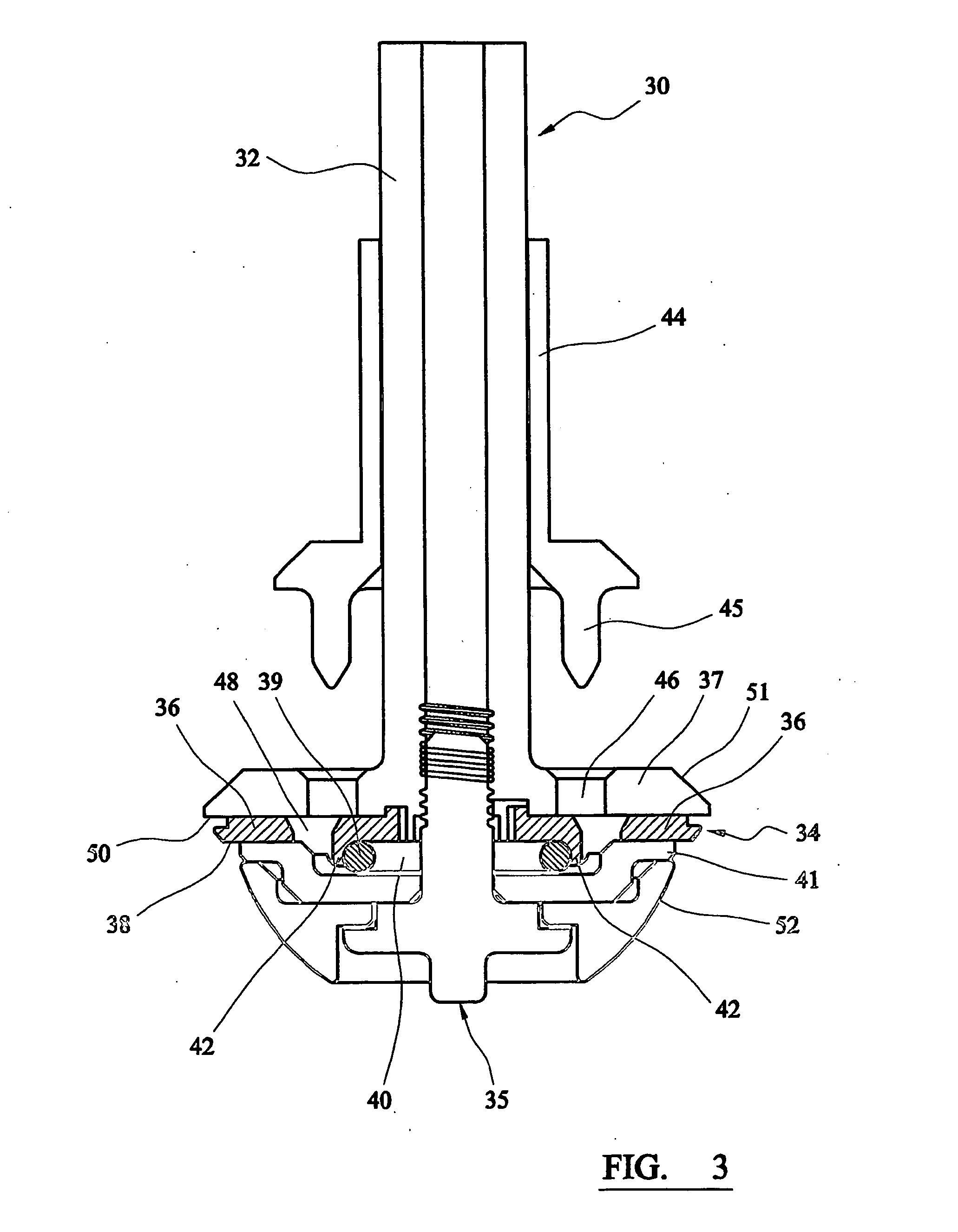

[0047]Referring to the drawings, FIG. 1 shows an acetabular cup 2 which has a generally hemispherical shape. It is formed from a cobalt-chromium based alloy. The external surface of the cup has a porous layer 4 formed on it, which is provided by particles which are sintered so that they bond to one another and to the surface. The use of this technique to create a porous surface is known, and is used in connection with products sold by DePuy Orthopaedics Inc under the trade mark POROCOAT. Such a porous surface promotes fixation of the implant as a result of ingrowth of bone tissue.

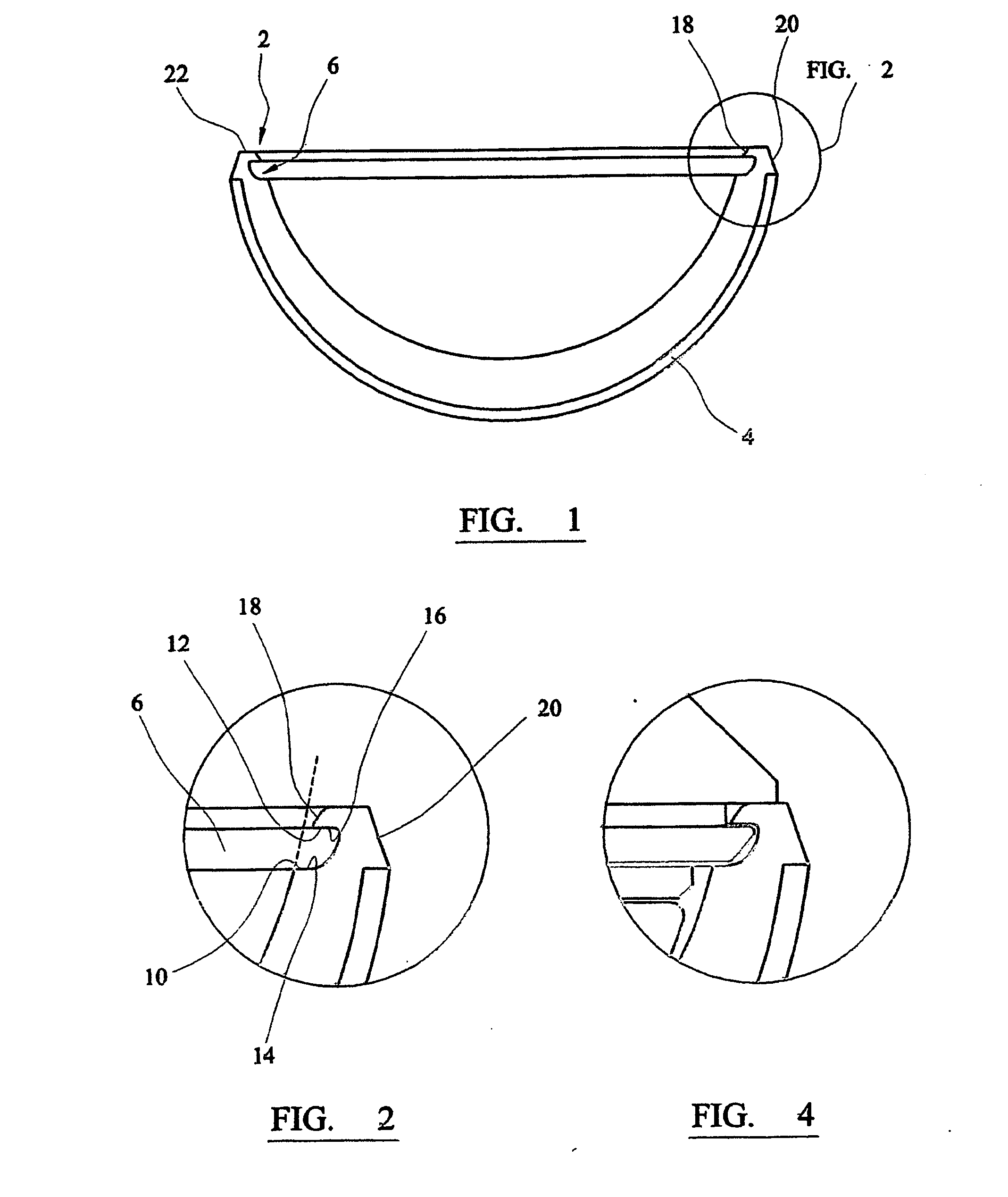

[0048]A groove 6 is formed in the internal surface of the cup close to the open mouth 8. The groove is defined by an inner lip 10, an outer lip 12, and by opposite walls 14, 16 which are parallel at the open edge of the groove. Preferably, the walls of the groove are approximately perpendicular to the axis of polar the cup component.

[0049]The internal surface of the cup within the region defined by the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com