Method and apparatus for treating natural gas and oil well drilling waste water

a technology for natural gas and oil wells, applied in the nature of treatment water, multi-stage water/sewage treatment, separation processes, etc., can solve the problems of limiting the ability to dispose of or treat this water by conventional means, unsuitable for reuse, and high cost of disposal of water and organically contaminated solids contained therein, so as to improve chemical efficiency and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be described in connection with certain preferred embodiments. However, it is to be understood that there is no intent to limit the invention to the embodiments described. On the contrary, the intent is to cover all alternatives, modifications, and equivalents as may be included within the spirit and scope of the invention as defined by the appended claims.

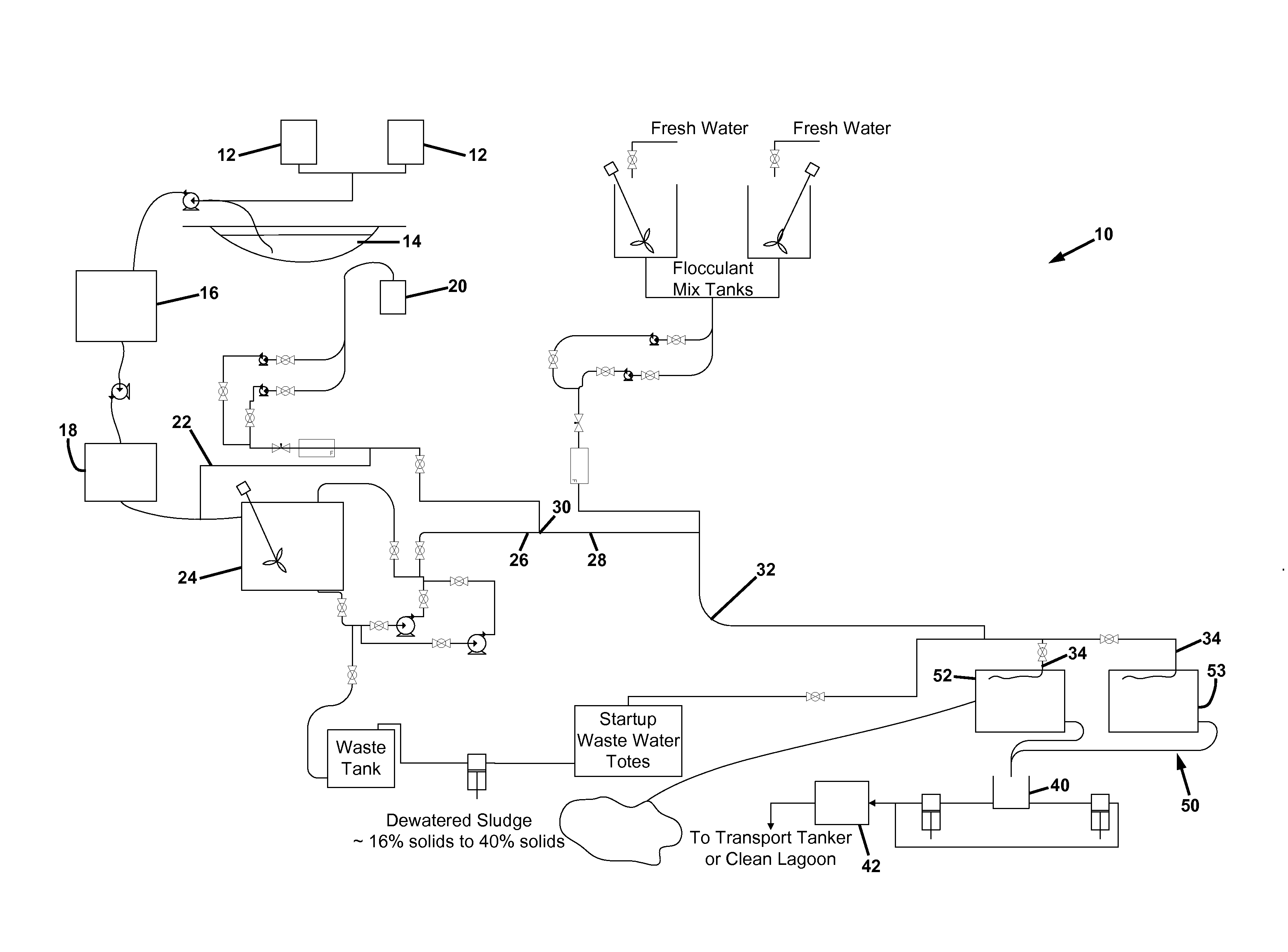

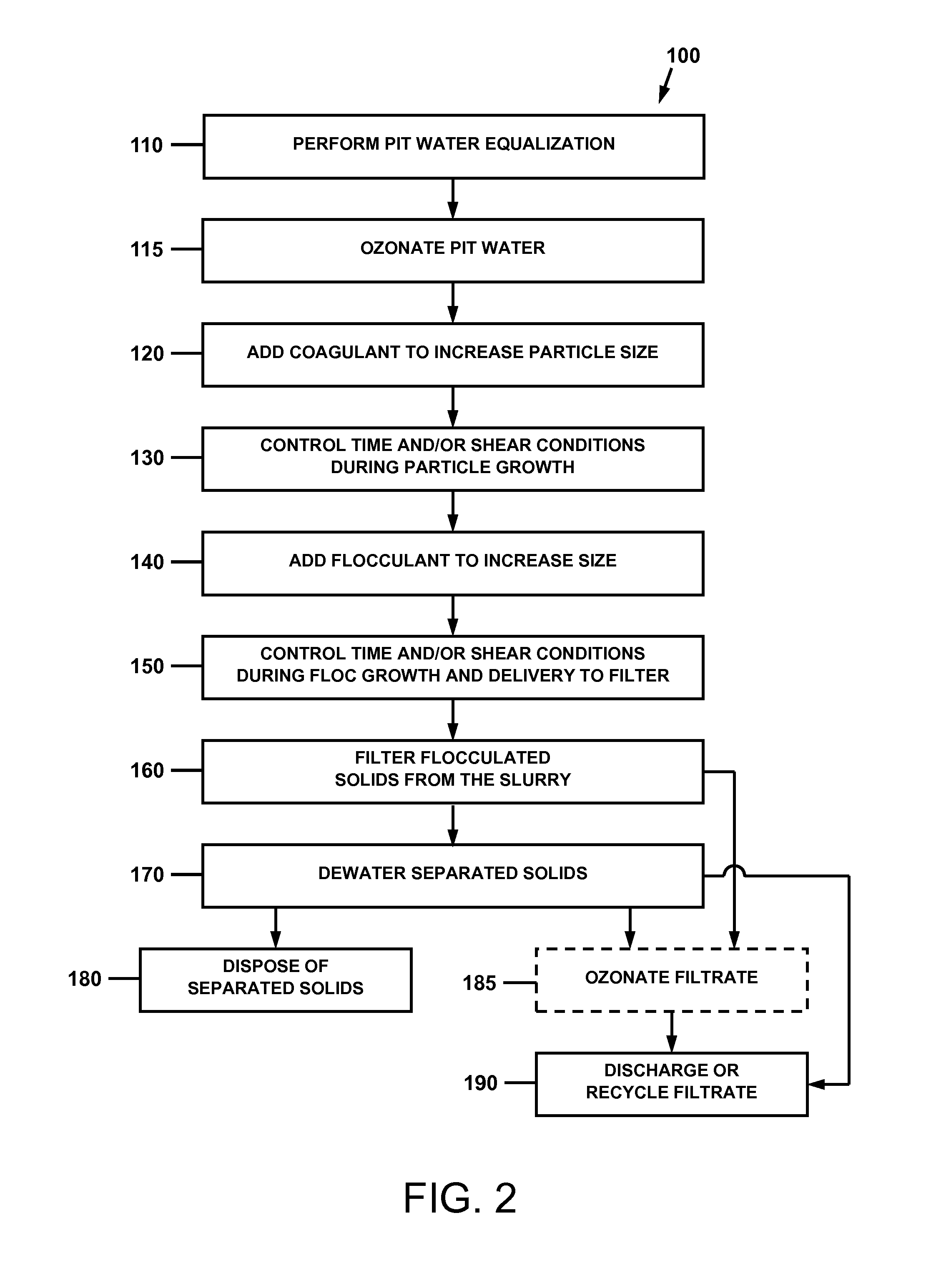

[0033]For a general understanding of the present invention, reference is made to the drawings. In the drawings, like reference numerals have been used throughout to designate identical elements. It is to be understood that the labeling of the vessels, conduits, pumps, filters, and other process equipment with dimensions, volumes, flow rates, capacities, materials of construction, and other specifications is meant to be exemplary only, and not limiting with respect to the instant apparatus and method. The apparatus and method may be operated in many other suitable configurations within the scope of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com