Building system with multi-function insulation barrier

a multi-functional, building technology, applied in the direction of walls, ceilings, building repairs, etc., can solve the problems of reducing the aesthetic appeal of the final wall, more serious situation, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

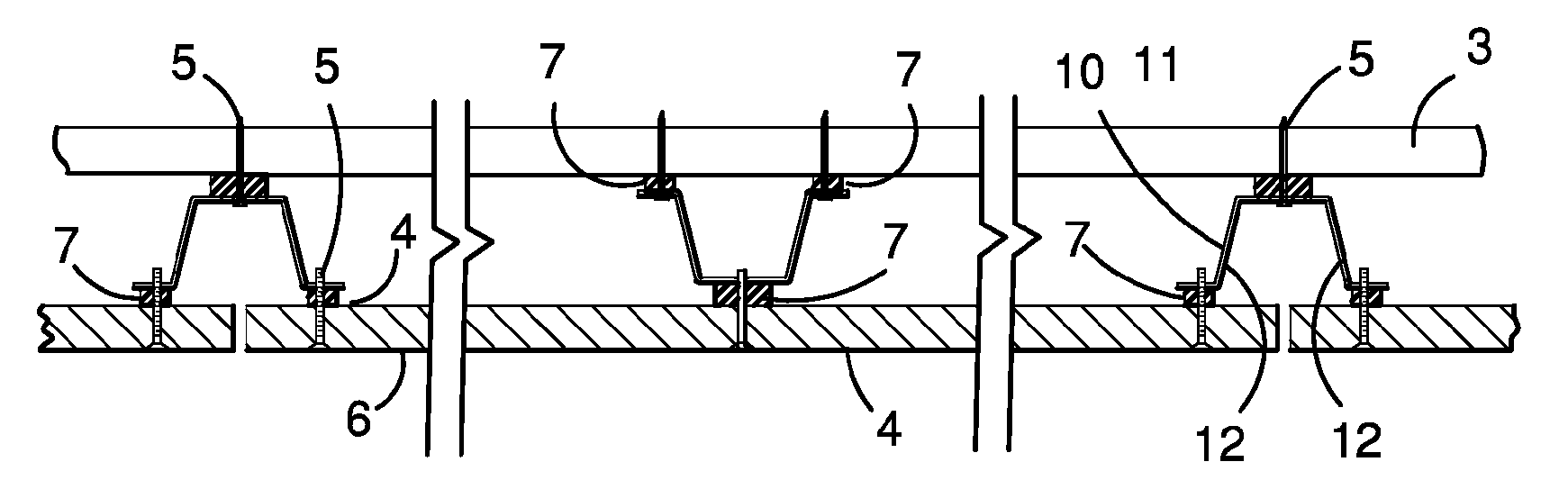

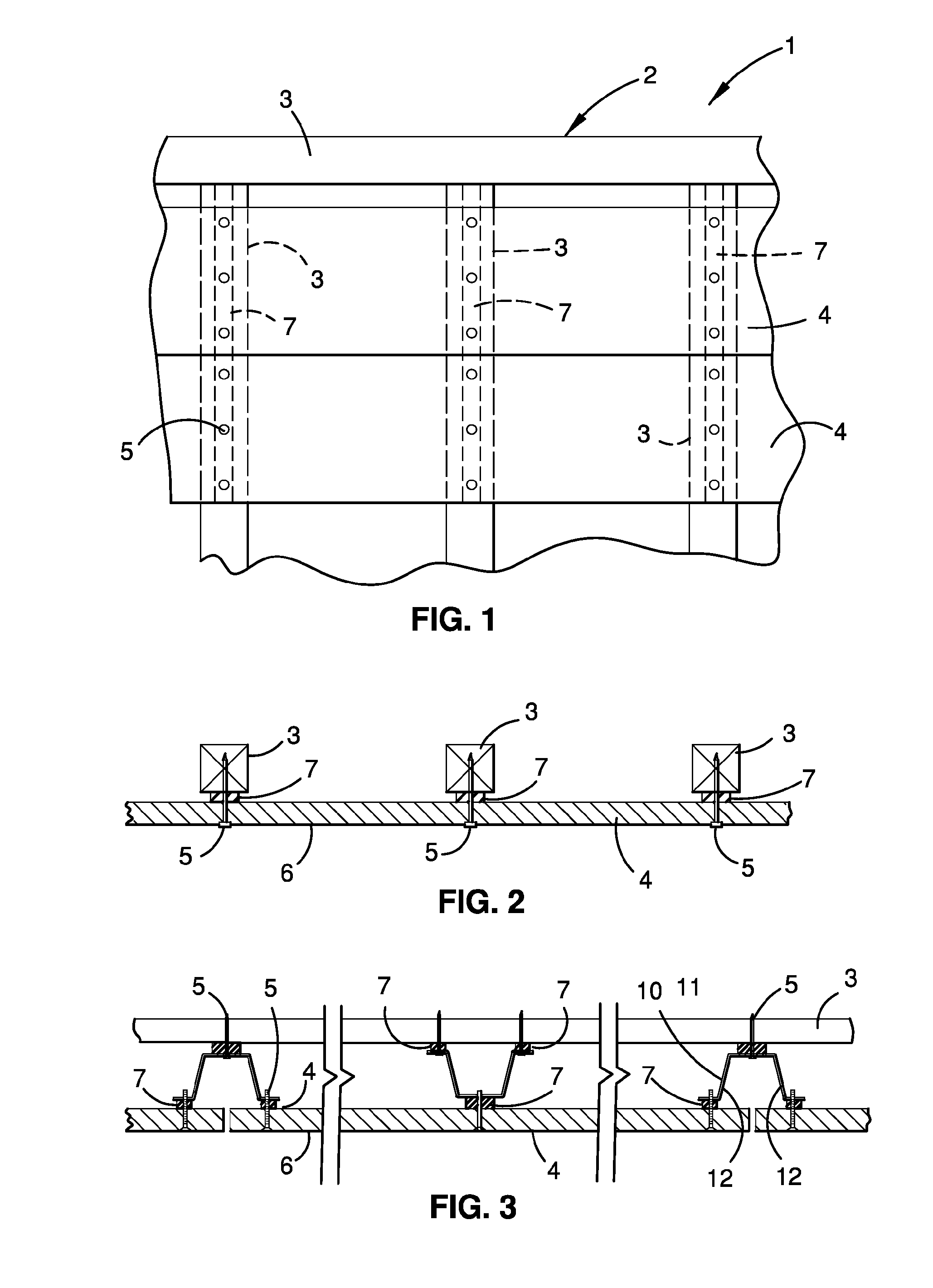

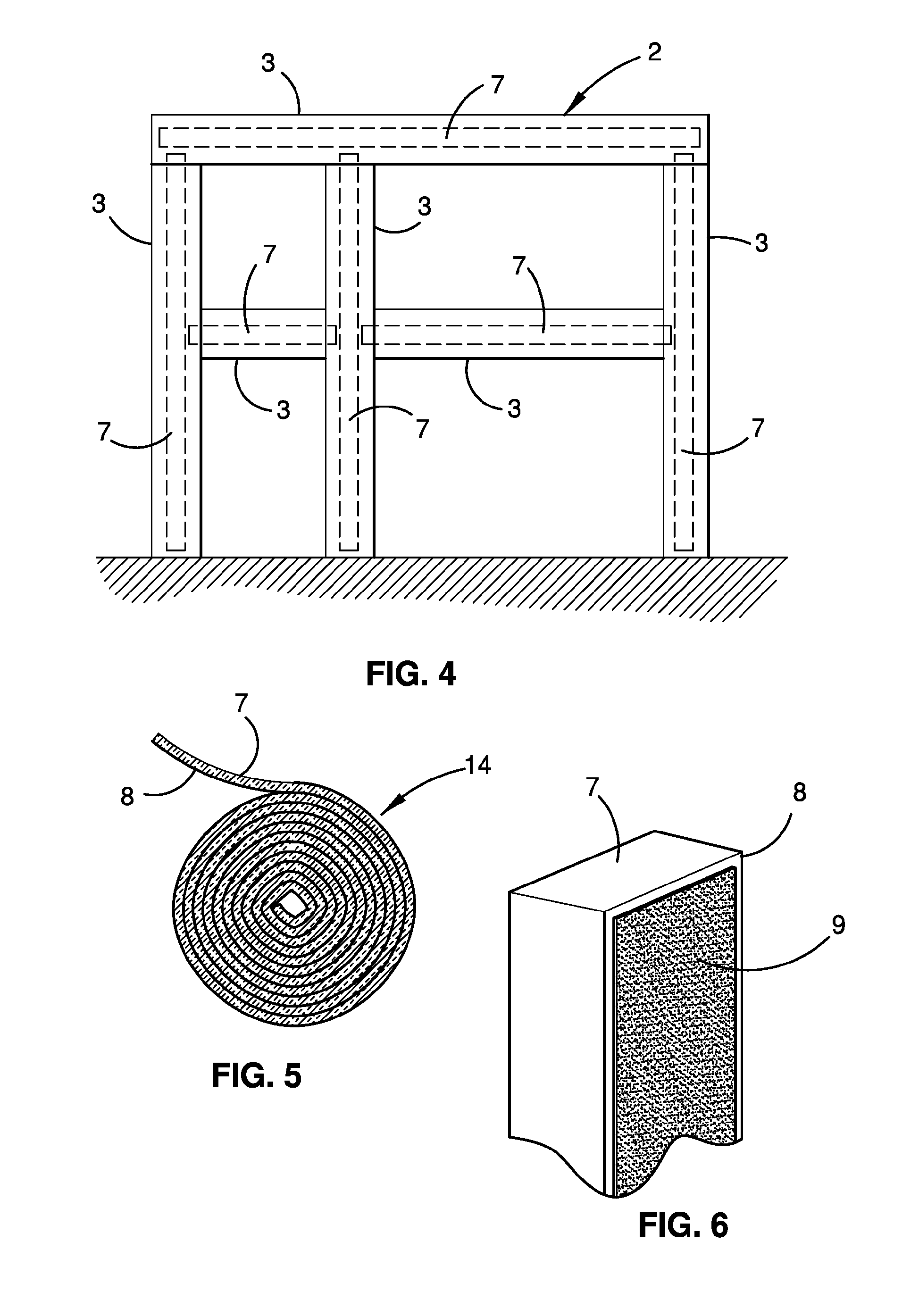

[0064]Referring to the drawings, the building section 1 includes a sub-structure in the form of a frame 2. The frame 2 is formed from a series of interconnected frame members 3 including a plurality of substantially vertical frame members and a plurality of substantially horizontal frame members. As will be described in greater detail below, the frame members 3 may be made from timber or metal such as steel.

[0065]For the sake of clarity, the following description will be made with reference to a wall frame. However, those skilled in the art will appreciate that the frame 2 may be a section of any suitable building frame including a wall frame, a sub-floor frame, a ceiling frame and a roof frame. It will be further appreciated by those skilled in the art that the present invention is not limited to the sub-structures listed here. In addition, it is to be understood that certain frames may be inclined, rather than being arranged to lie in a substantially vertical or horizontal plane.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com