Control for a tankless water heater used with a solar water heating system

a solar water heating and water heater technology, applied in the direction of domestic hot water supply systems, heating types, lighting and heating apparatuses, etc., can solve the problems of increasing the number of heating system operating cycles, reducing the life of equipment, and requiring additional equipment, so as to prevent needless powering of auxiliary power systems, reduce energy consumption, and eliminate needless cycling of auxiliary systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

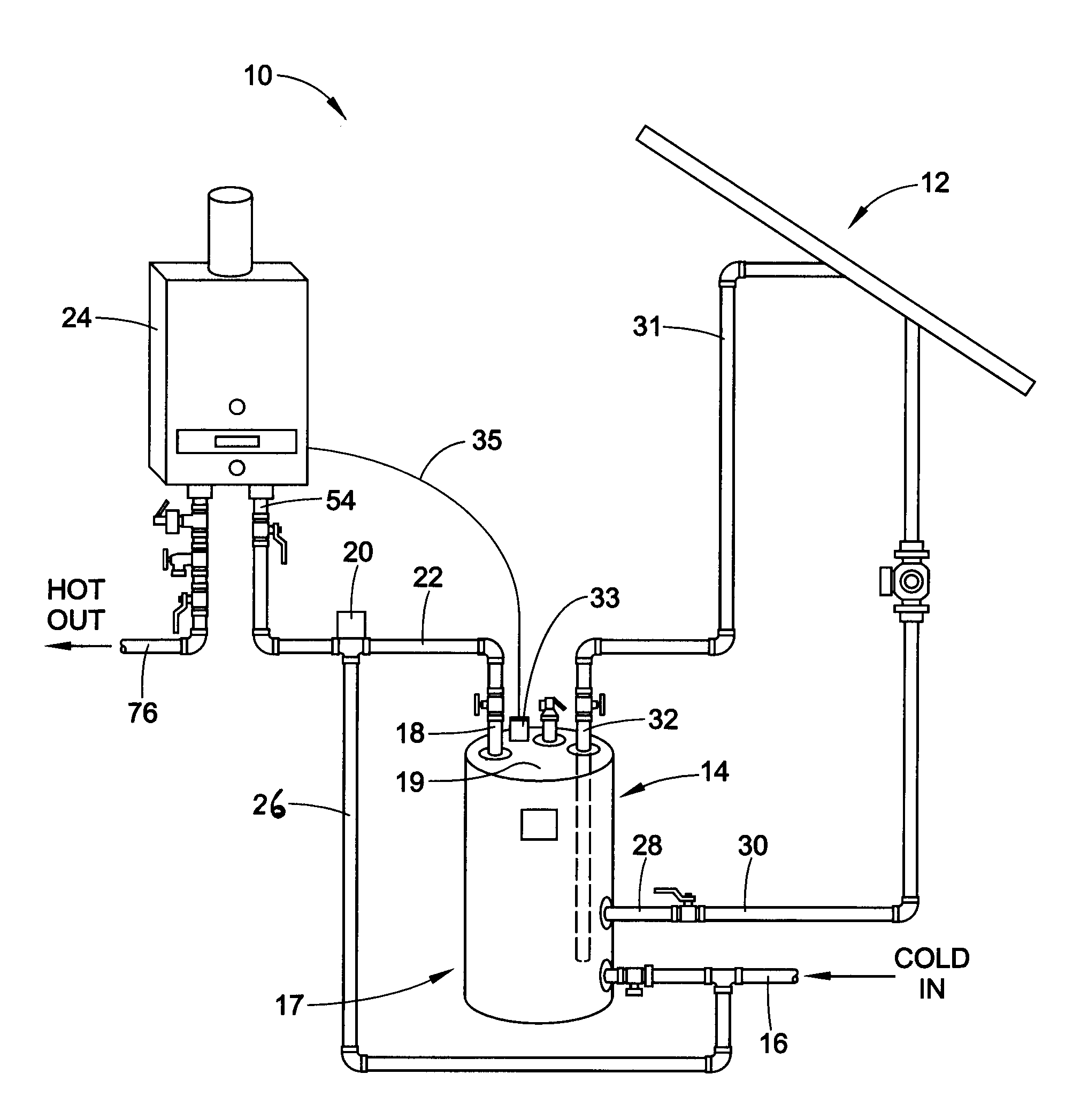

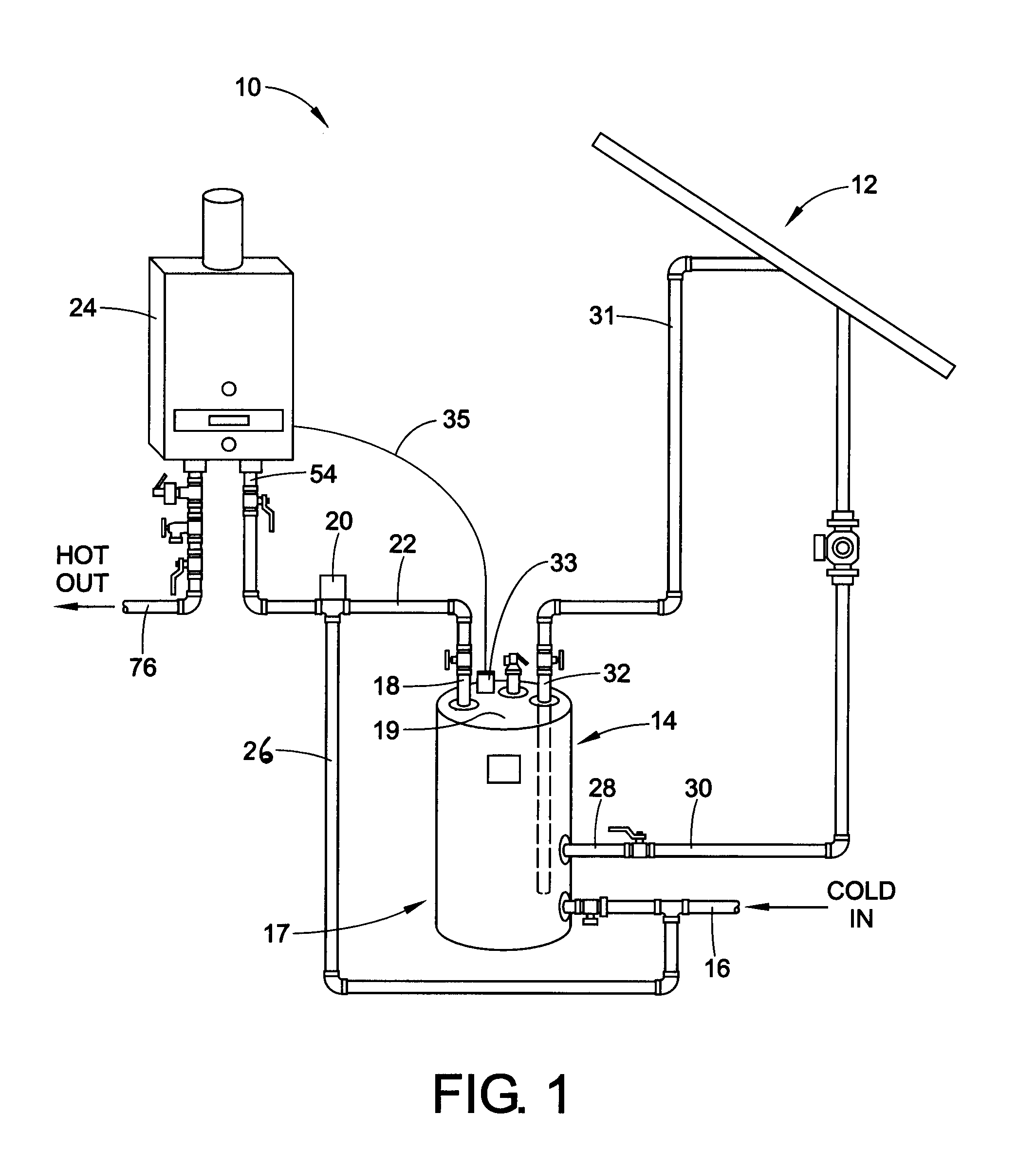

[0021]Referring to FIG. 1, a solar water heater supply system 10 in accordance with a preferred embodiment of the present disclosure is shown.

[0022]The system 10 includes a solar collector 12 which may be of conventional design which collects and provides heat to a heat transfer fluid that then transfers the heat from the collector 12 to water contained in a conventional insulated water heater storage tank 14 having a cold water inlet 16 near a bottom 17 of the tank and a hot water outlet 18 near a top 19 of the tank. A thermostatic mixing valve 20 is provided at a hot water outlet pipe 22 which mixes cold water from a cold water supply line 26 with the hot water from hot water line 22 to provide the user with water at the user selected water temperature.

[0023]Such mixing valves 20 are typically used in solar hot water heating systems because it is desirable to store water in the tank at temperatures which may be higher than that desired for use by the user, for increased energy sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com