Oil dilution inhibiting apparatus and method

a technology of oil dilution and inhibiting apparatus, which is applied in the direction of engine starters, electric control, machines/engines, etc., can solve the problems of engine lowness, oil dilution by unburnt fuel likely more than expected, etc., and achieve the effect of increasing the oil temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

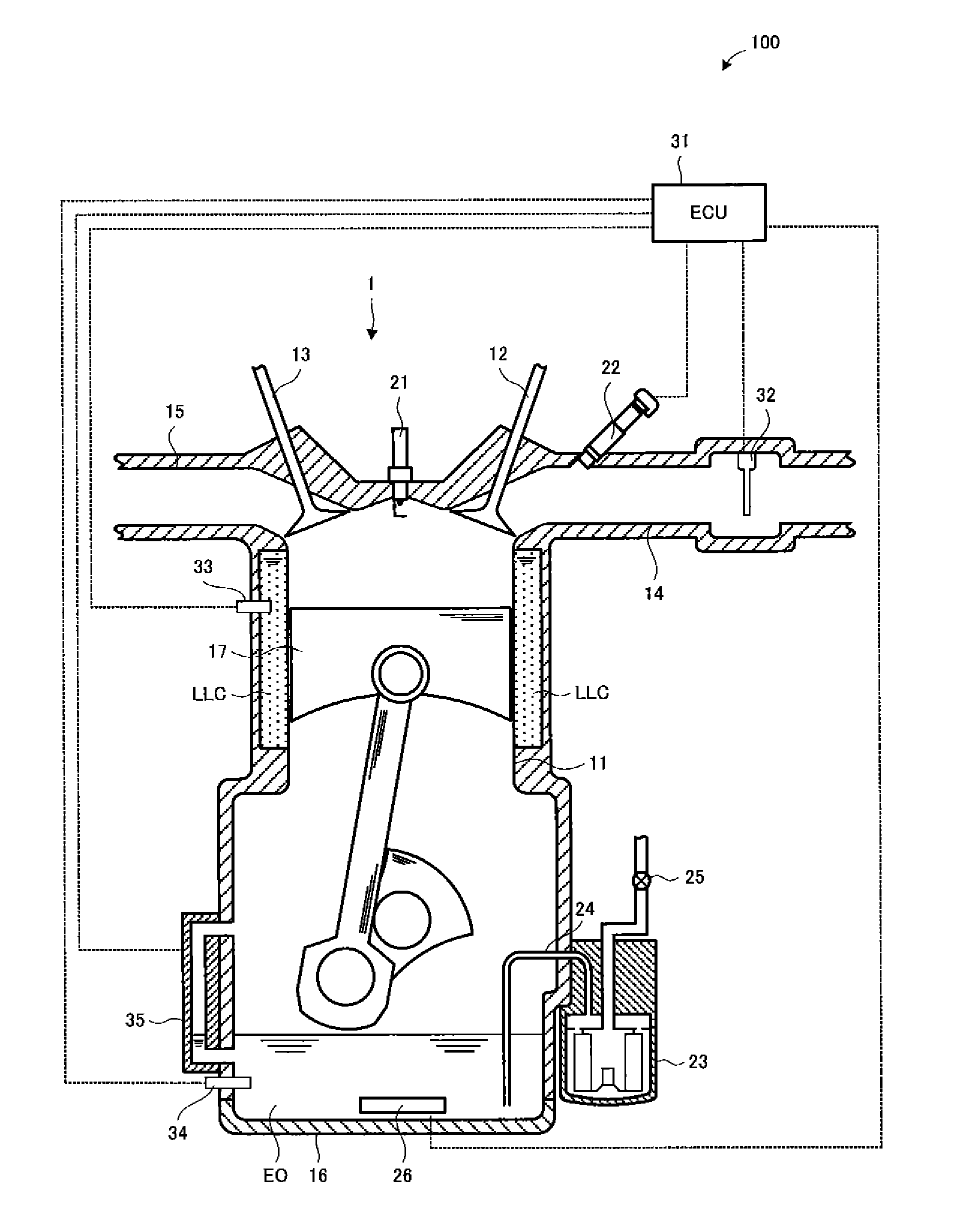

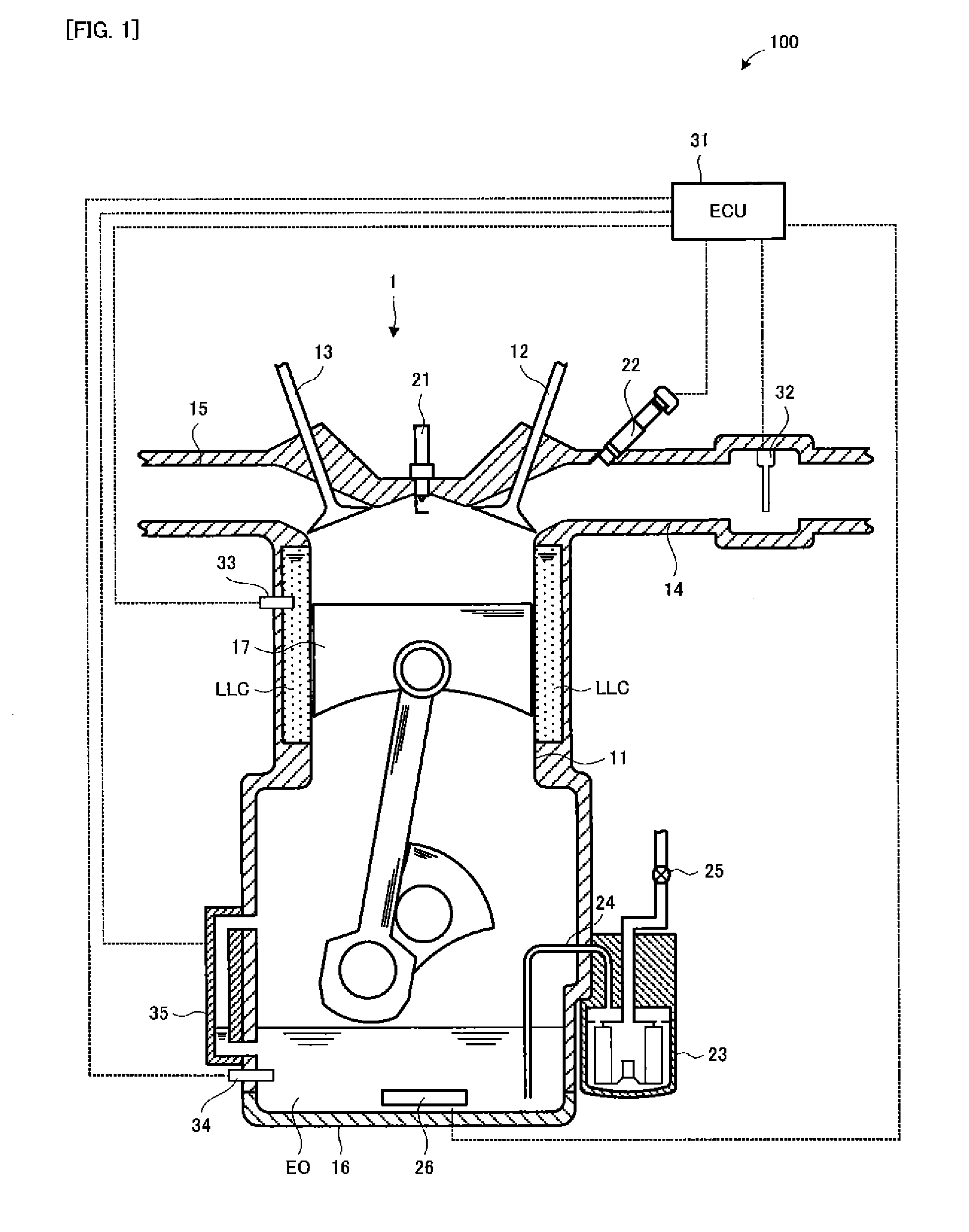

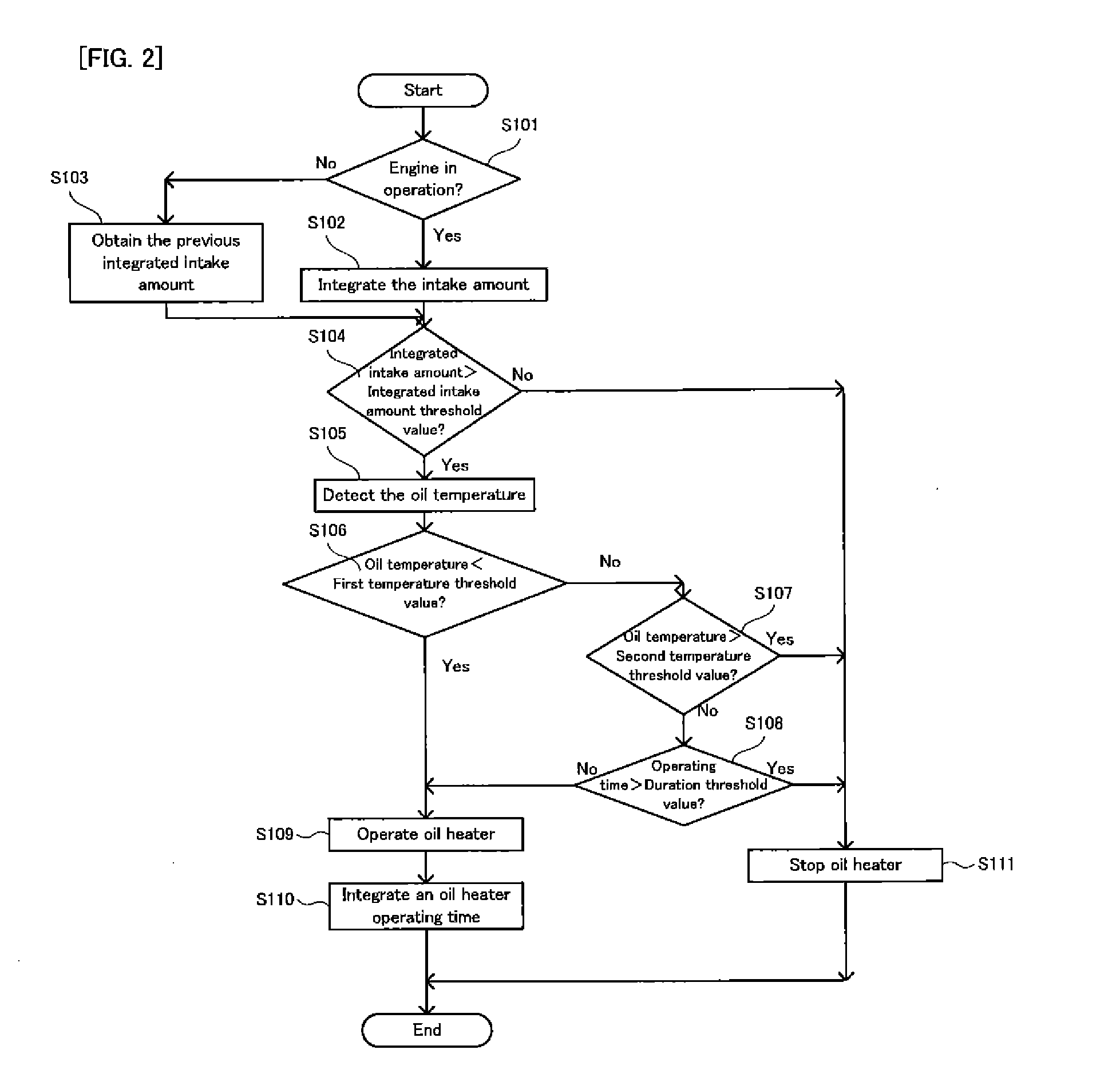

[0081]A first embodiment of the oil dilution inhibiting apparatus of the present invention will be explained with reference to FIG. 1 and FIG. 2.

[0082]FIG. 1 is a block diagram showing the structure of an oil dilution inhibiting apparatus in the first embodiment.

[0083]In FIG. 1, an engine 1 provided for a vehicle (not illustrated) on which an oil dilution inhibiting apparatus 100 is mounted is provided with: a cylinder 11; an intake valve 12; an exhaust valve 13; an intake passage 14; an exhaust passage 15; an oil pan 16; a piston 17; an ignition plug 21; a fuel injection valve 22; an oil filter 23; and an oil heater 26.

[0084]Engine oil EO accumulated in the oil pan 16 flows into the oil filter 23 via an oil inflow passage 24. The engine oil EO which has passed through the oil filter 23 is pumped by the oil pump 25 and is supplied to a main gallery not illustrated. The fuel injection valve 22 is controlled by an ECU (Electronic Control Unit) 31 to inject alcohol fuel accumulated in ...

second embodiment

[0127]A second embodiment of the oil dilution inhibiting apparatus of the present invention will be explained with reference to FIG. 5. Except that the second embodiment has a different oil dilution inhibiting process performed by the ECU, the second embodiment has the same configuration as in the first embodiment. Thus, in the second embodiment, the overlap explanation with the first embodiment will be omitted. The common point will carry the same reference numeral in the drawing, and basically only a different point will be explained with reference to FIG. 5. FIG. 5 is a flowchart showing the oil dilution inhibiting process performed by the ECU in the second embodiment, to the same effect as in FIG. 2.

(If Oil Heater is OFF)

[0128]In FIG. 5, if the oil heater 26 is OFF (i.e. if it is not in the oil heating mode), firstly, the ECU 31 detects the state of the vehicle (step S301). Specifically, for example, the ECU 31 detects a vehicle speed, vehicle inclination, the number of revoluti...

third embodiment

[0148]A third embodiment of the oil dilution inhibiting apparatus of the present invention will be explained with reference to FIG. 6. Except that the third embodiment has a different oil dilution inhibiting process performed by the ECU, the third embodiment has the same configuration as in the first embodiment. Thus, in the third embodiment, the overlap explanation with the first embodiment will be omitted. The common point will carry the same reference numeral in the drawing, and basically only a different point will be explained with reference to FIG. 6. FIG. 6 is a flowchart showing the oil dilution inhibiting process performed by the ECU in the third embodiment, to the same effect as in FIG. 2.

(If Oil Heater is OFF)

[0149]In FIG. 6, if the oil heater 26 is OFF (i.e. if it is not in the oil heating mode), firstly, the ECU 31 obtains the oil temperature of the engine oil EO via the oil temperature sensor 34 (step S401). Then, the ECU 31 judges whether or not the obtained oil tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com