Smoking Articles and Method for Manufacturing Smoking Articles

a technology for smoking articles and smoking sheets, applied in the field of smoking articles and manufacturing methods, can solve the problems of inability to ensure, cost of additive materials, and the cost of such papers is typically four to five times the cost of standard cigarette paper, and achieve the effect of not affecting the efficiency of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

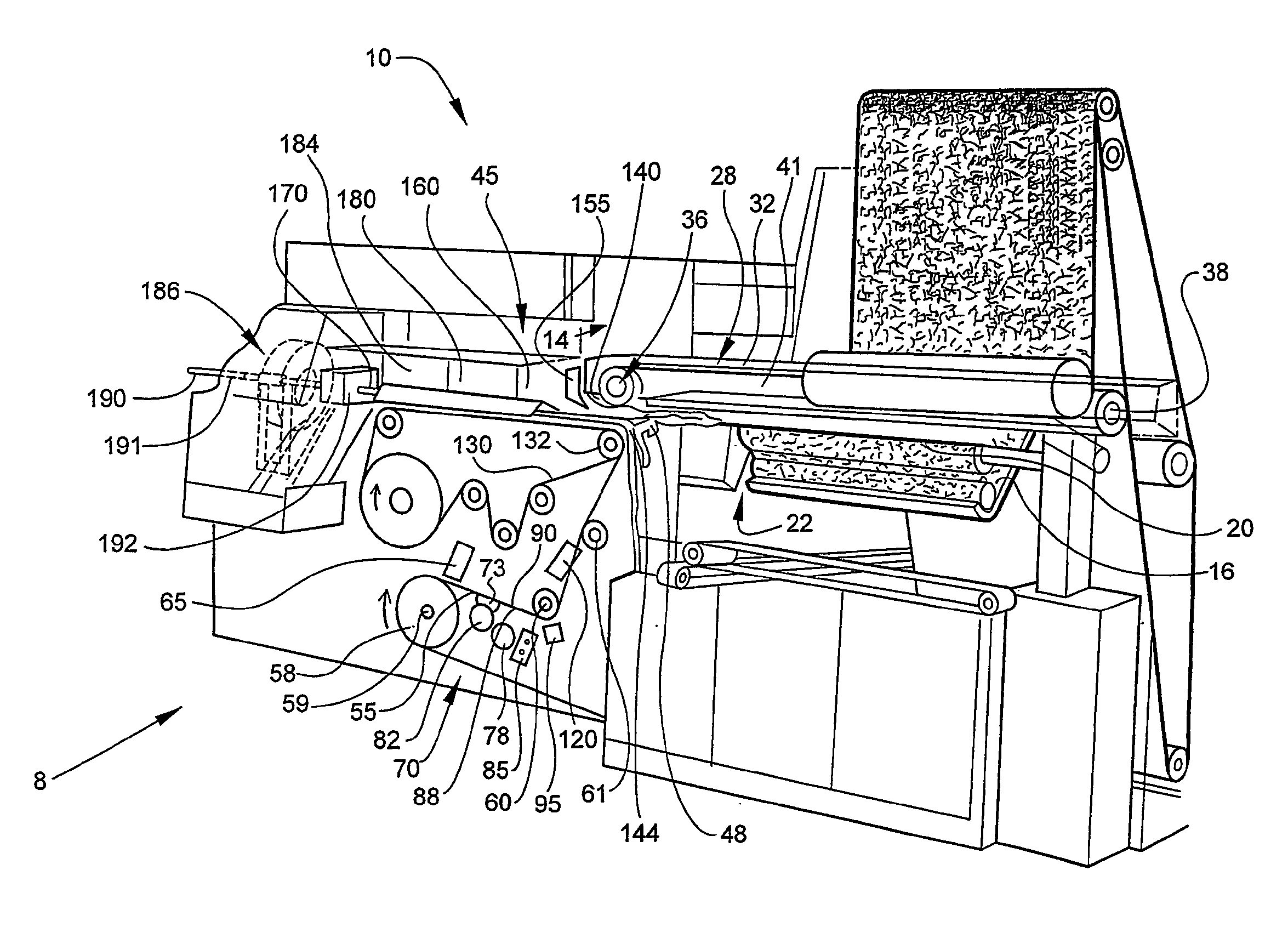

[0028]FIG. 1 shows a cigarette making apparatus 10 of a type known in the art, which has been modified to apply a burn retardant additive material to a wrapping paper prior to forming the wrapping paper into cigarettes. The cigarette making apparatus 10 includes a source of tobacco material 20 which is provided to chimney region 16 where it is blown upwards by air stream 22 onto a lower outside surface of endless conveyor system 28. The endless conveyor system 28 includes a porous belt 32 having a low pressure region 41 into which the tobacco material 20 is drawn, wherein the porous belt 32 retains the tobacco material against the bottom of the conveyor system 28 to form a stream of tobacco material conveyed towards a garniture section 45.

[0029]A paper supply section 8 is provided to supply a continuous web of paper wrapping material 55 from a roll 58 through a series of rollers and guide posts 60, 61 to the garniture section 45 where the wrapping material 55 is wrapped around the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

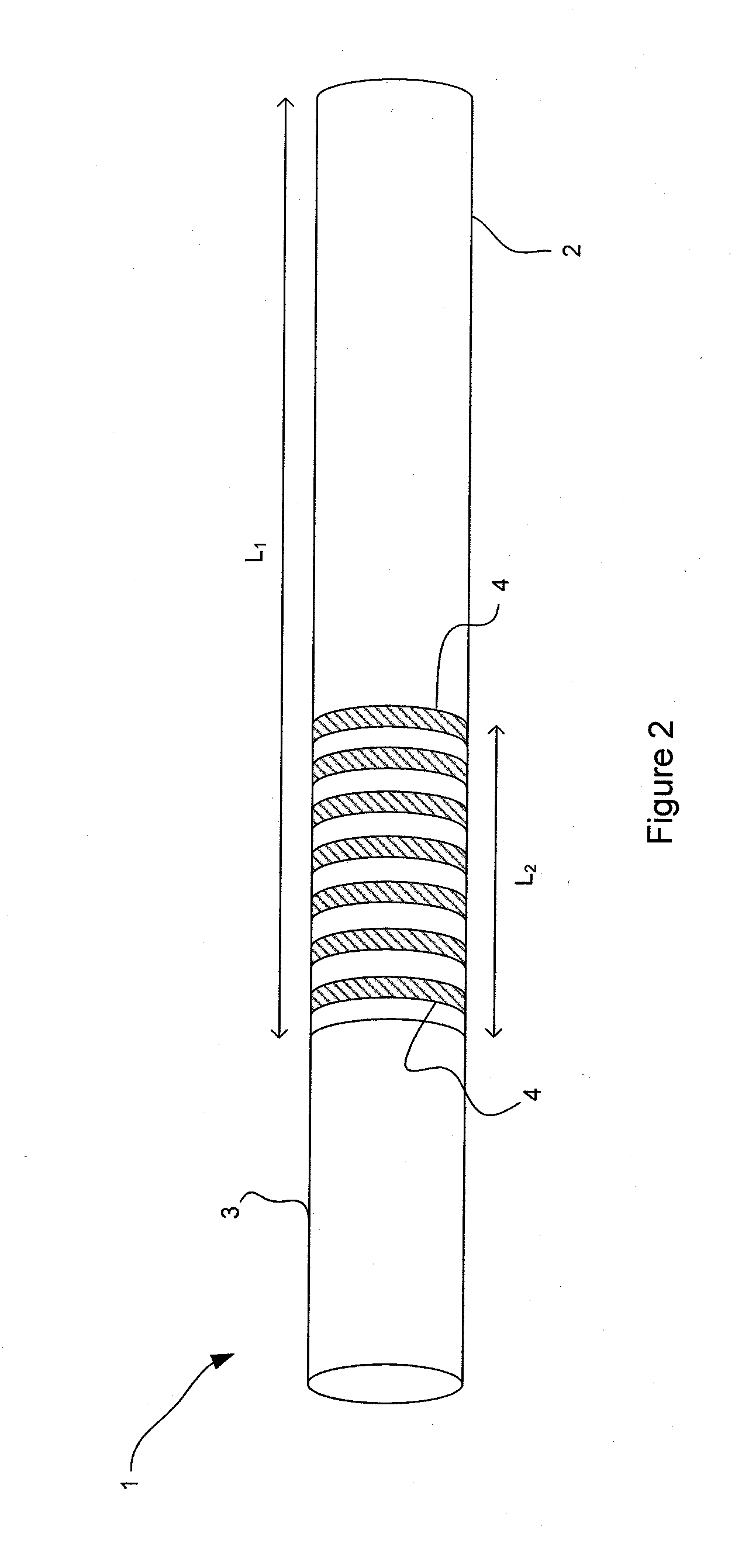

| length l1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com