Outside Air Shut-Off Container and Pressure-Reducible Processing Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

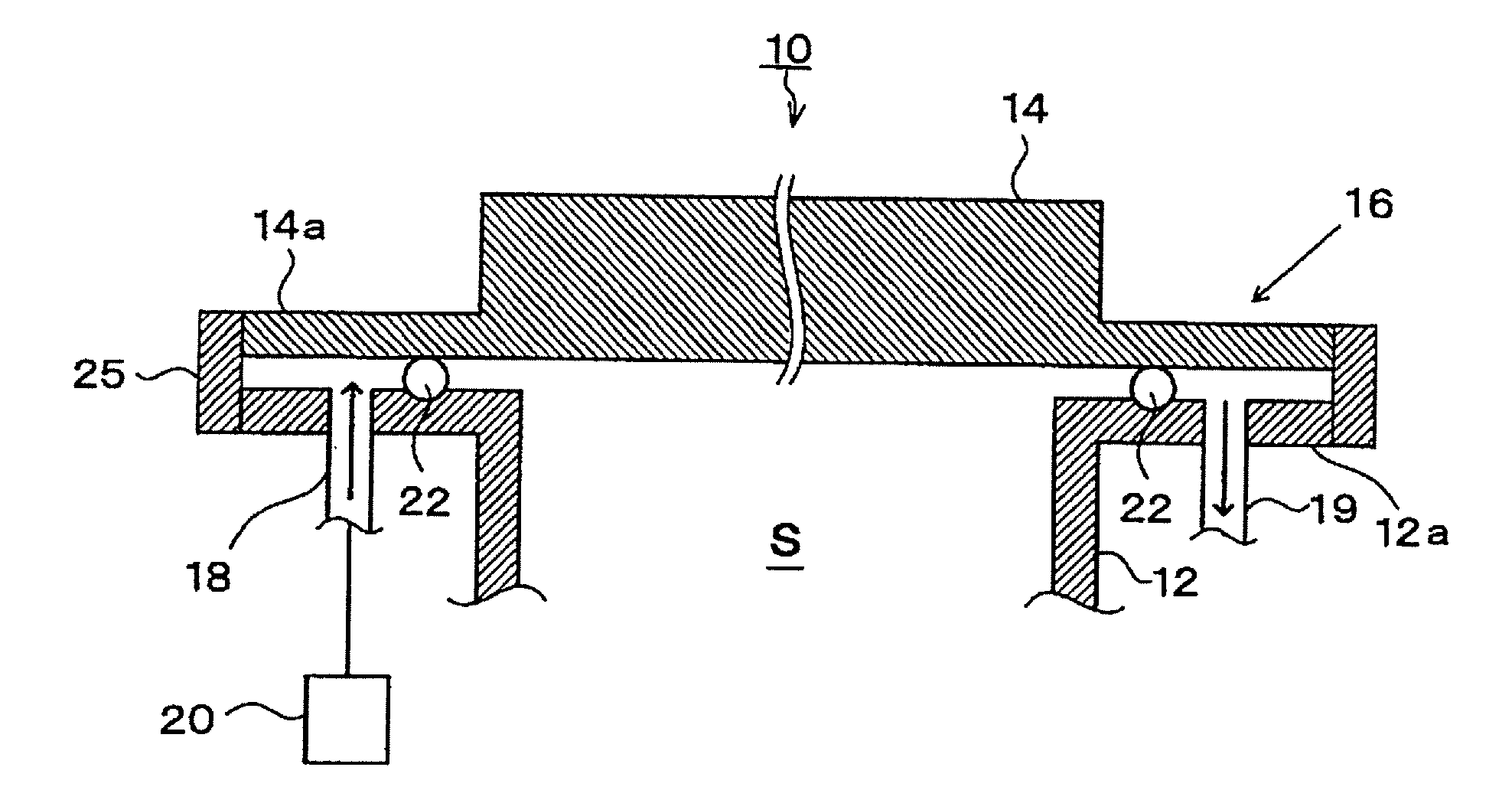

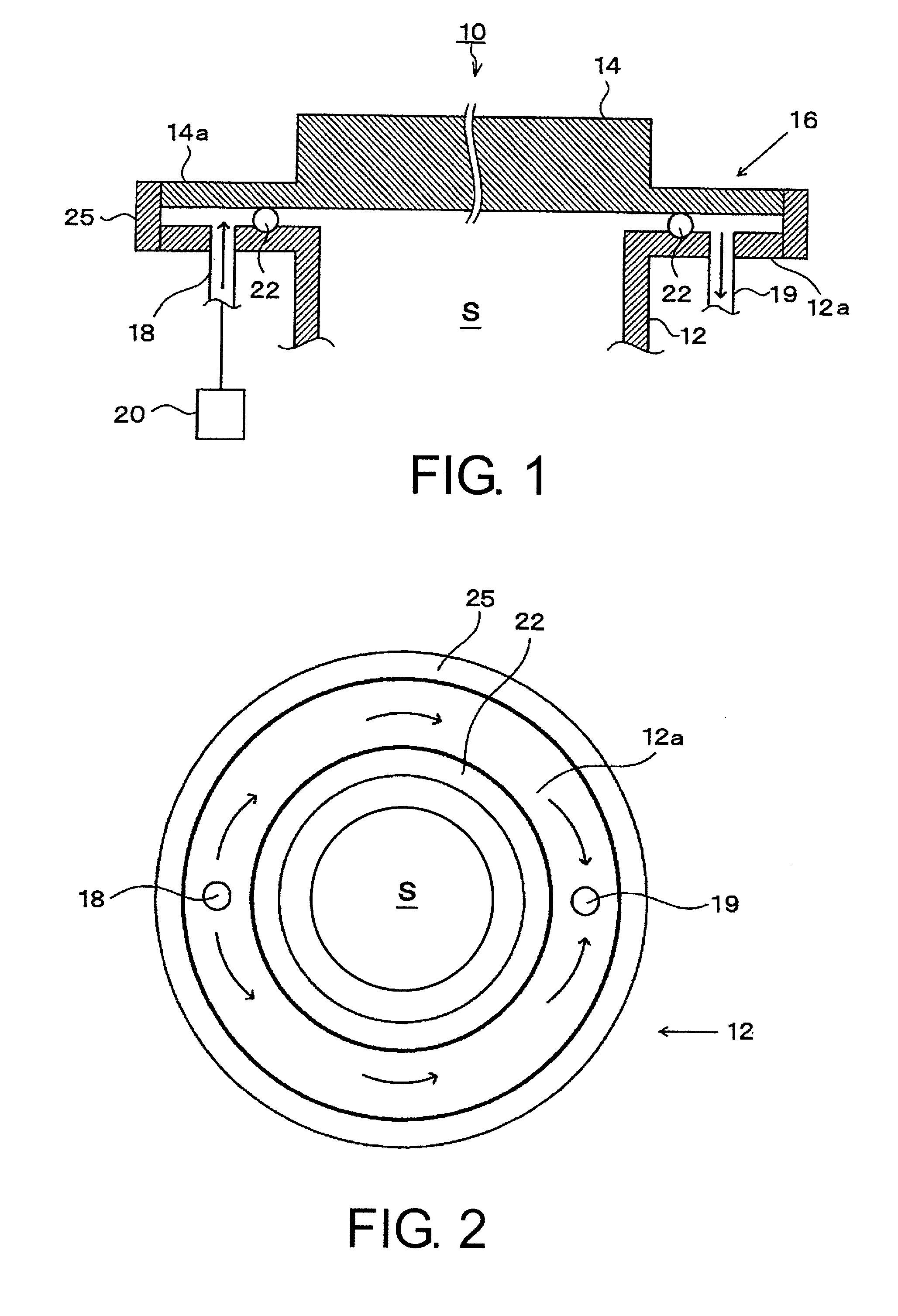

[0024]Referring to FIG. 1, a pressure-reducible processing apparatus according to the present invention is formed by, for example, a plasma processing apparatus having an outside air shut-off container 10 as illustrated. The illustrated outside air shut-off container 10 has a process chamber 12 that defines a processing space therein, a cover member 14 mounted on the process chamber 12, and a hermetically sealing mechanism portion 16 for hermetically sealing the process chamber 12 and the cover member 14. The illustrated process chamber 12 has a cylindrical shape. The process chamber 12 and the cover member 14 are made of aluminum or stainless steel.

[0025]The process chamber 12 has an upper end extending outward along its circumference so as to form a chamber protrusion, or a flange portion 12a. The cover member 14 has a lower end extending outward from its sidewall so as to form a cover member protrusion 14a.

[0026]A gas inlet is formed in the flange portion 12a of the illustrated ...

second embodiment

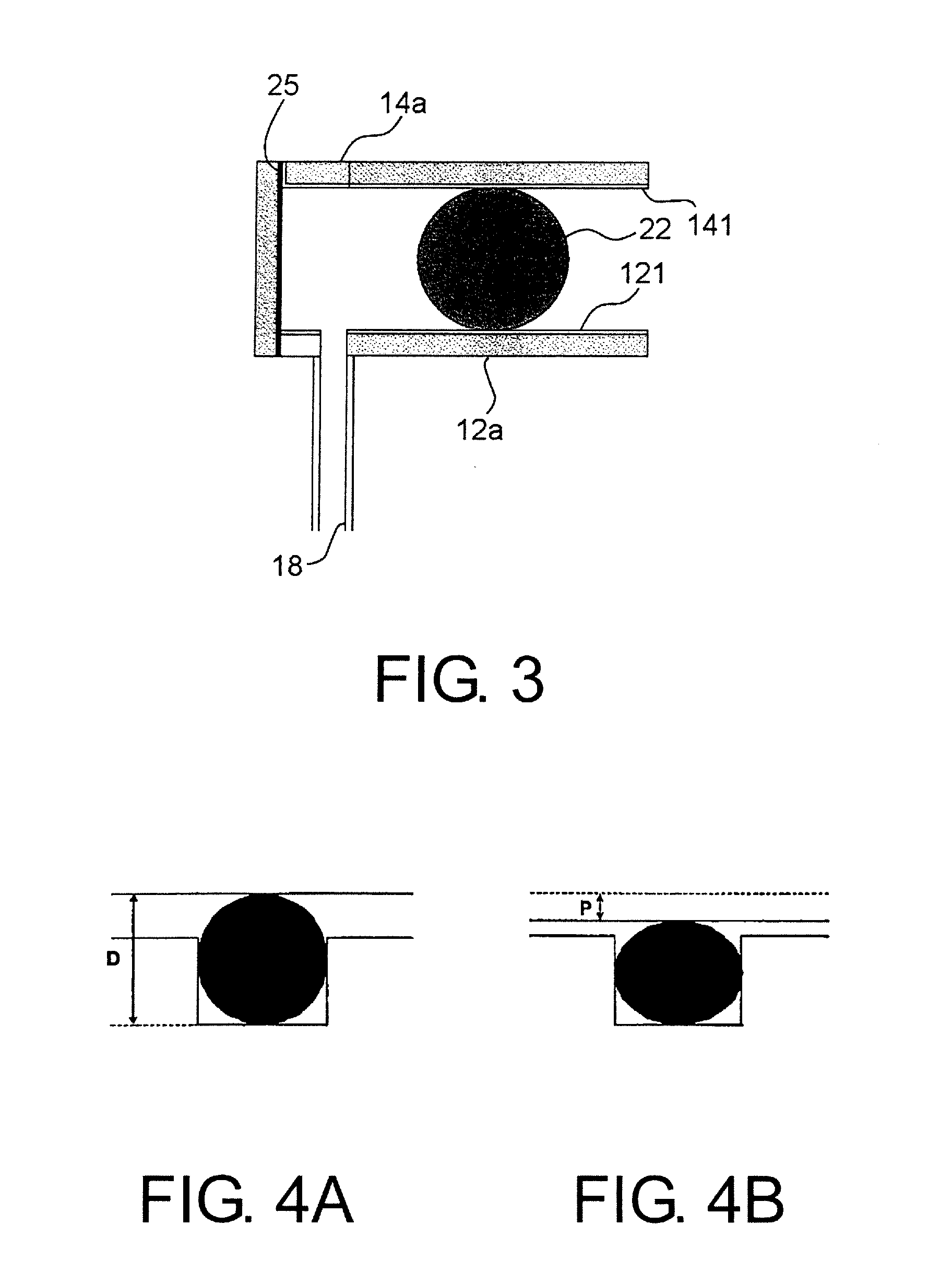

[0035]An outside air shut-off container according to the present invention will be described below with reference to FIG. 3, which shows part of FIG. 1 in an enlarged manner. In FIG. 3, the flange portion 12a of the process chamber 12 and the cover member protrusion 14a of the cover member 14 are formed of high-purity aluminum (S2M). Aluminum oxide layers 121 and 141 are provided at least in surface areas of the flange portion 12a and the cover member protrusion 14a of the cover member 14 with which the O-ring 22 is brought into contact.

[0036]Thus, with the aluminum oxide layers provided on the flange portion 12a and the cover member protrusion 14a, which are made of aluminum, the temperature at which pyrolysis takes place in the atmosphere (1% H2O / 20% O2 / Ar) can be increased to 150° C. or more. Therefore, degradation of the O-ring 22 due to pyrolysis can be prevented even though the O-ring 22 is heated to a high temperature.

[0037]An anodizing process using a nonaqueous solvent can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com