Energy storage vessel, systems, and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

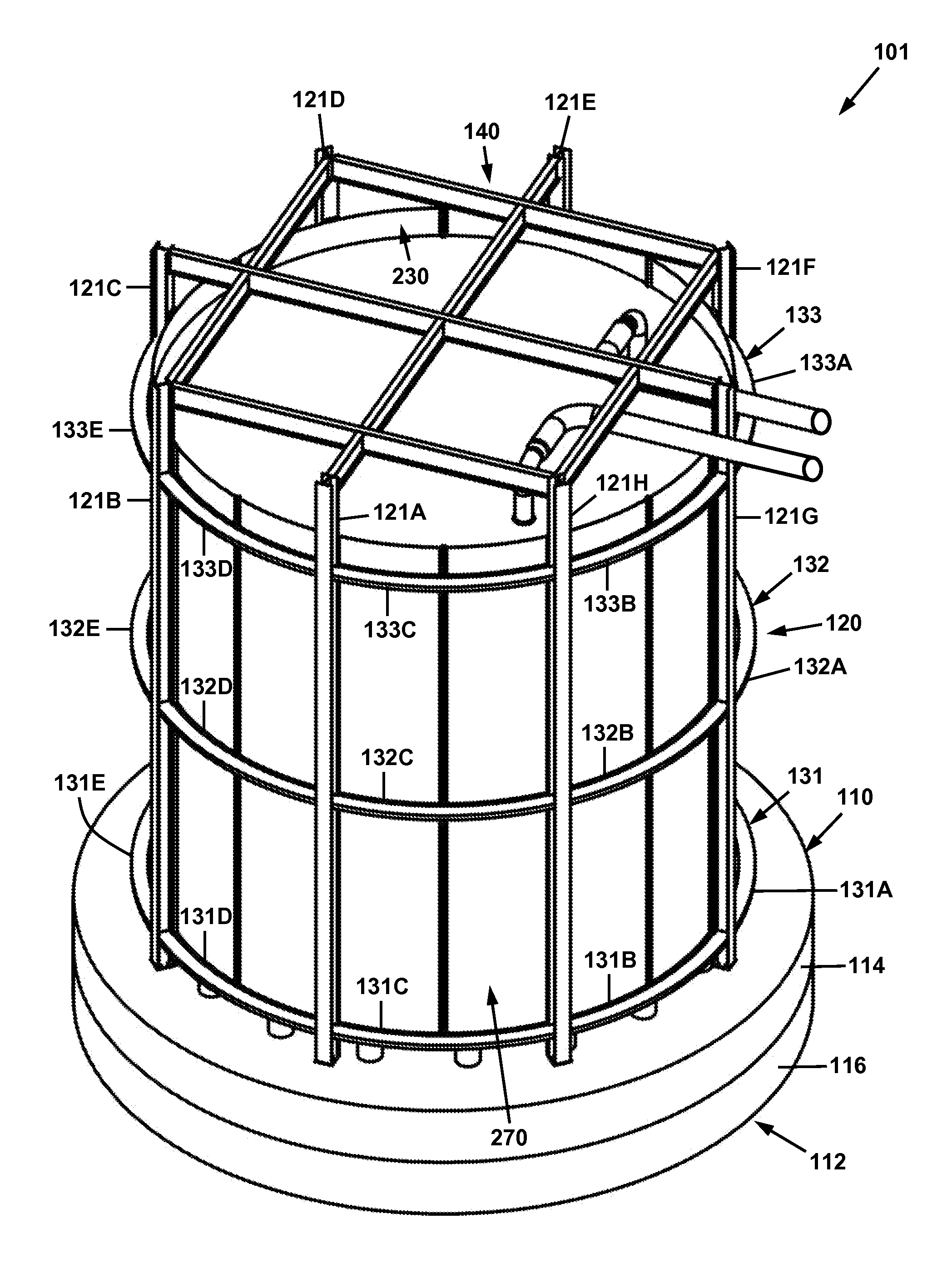

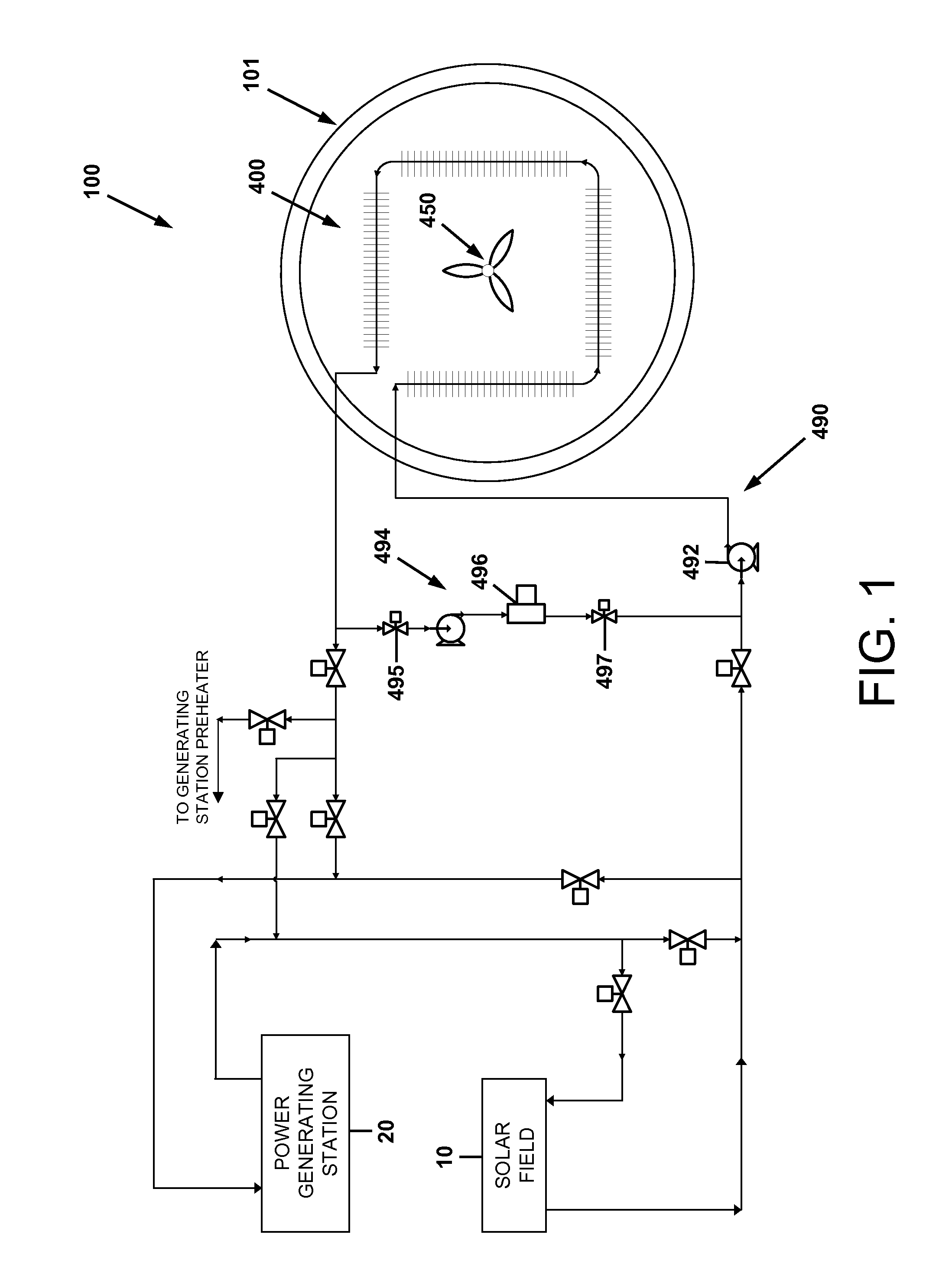

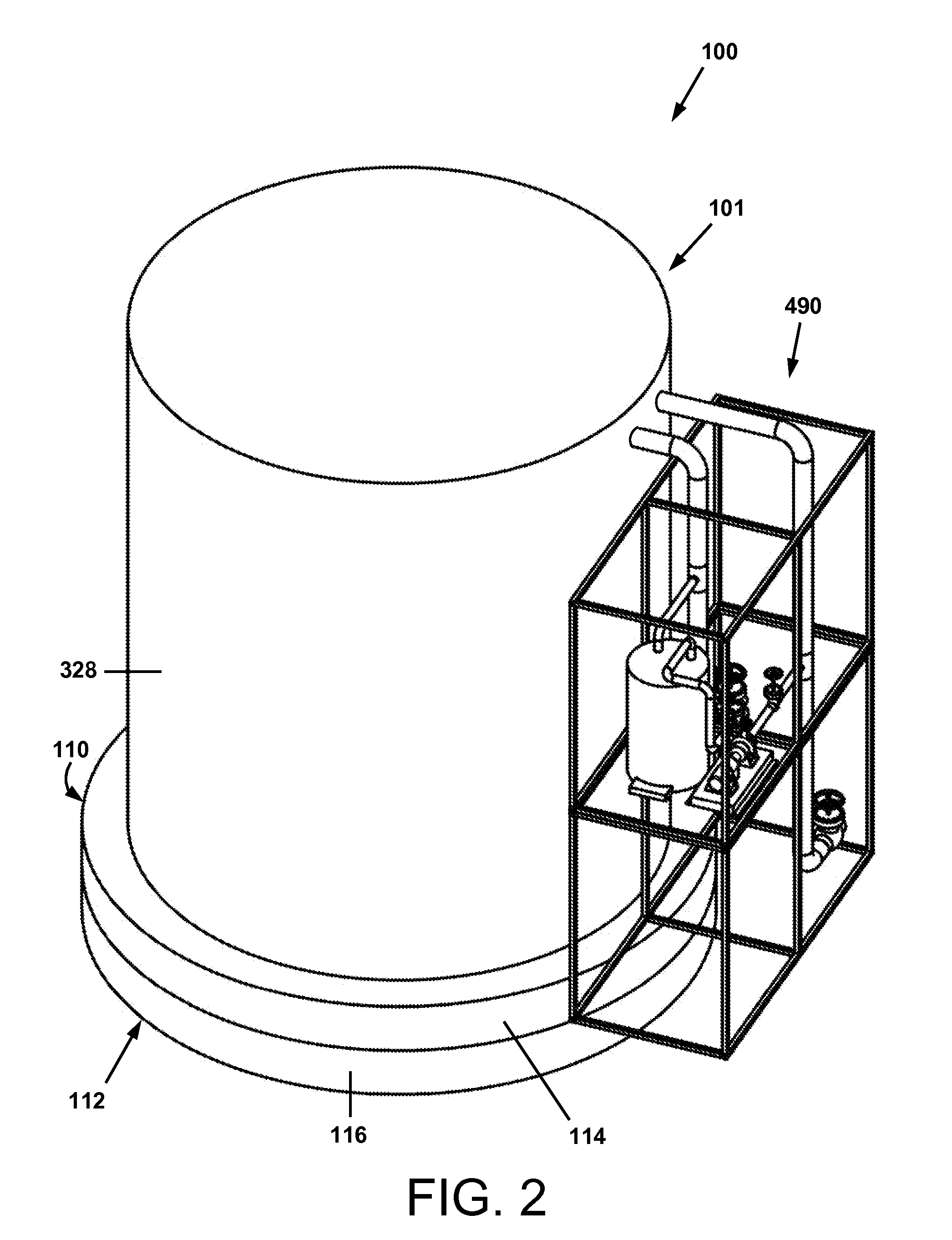

[0059]For a general understanding of the present invention, reference is made to the drawings. In the drawings, like reference numerals have been used throughout to designate identical elements.

[0060]FIG. 1 is a schematic illustration of a thermal storage system and method in accordance with the present disclosure. The thermal energy storage system 100 is comprised of a containment vessel 101, which contains a heat exchanger or an array 400 of heat exchangers immersed in a molten salt. The system 100 is further comprised of a liquid transfer unit 490 (that may be of a modular design), which circulates a heat transfer fluid through the heat exchangers during operation of the system 100. The liquid transfer unit 490 is comprised of liquid piping, various switching and control valves, a pump 492, and a pressure relief tank (not shown). The liquid transfer unit 490 may further include a heater loop 494 comprising an oil heater 496 and an expansion tank (not shown) for heating and circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com