Stable liquid pharmaceutical formulation of igg antibodies

a technology of igg antibodies and liquid formulations, applied in the field of stable liquid and high-concentration antibody formulations, can solve problems such as protein aggregates and particulates formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

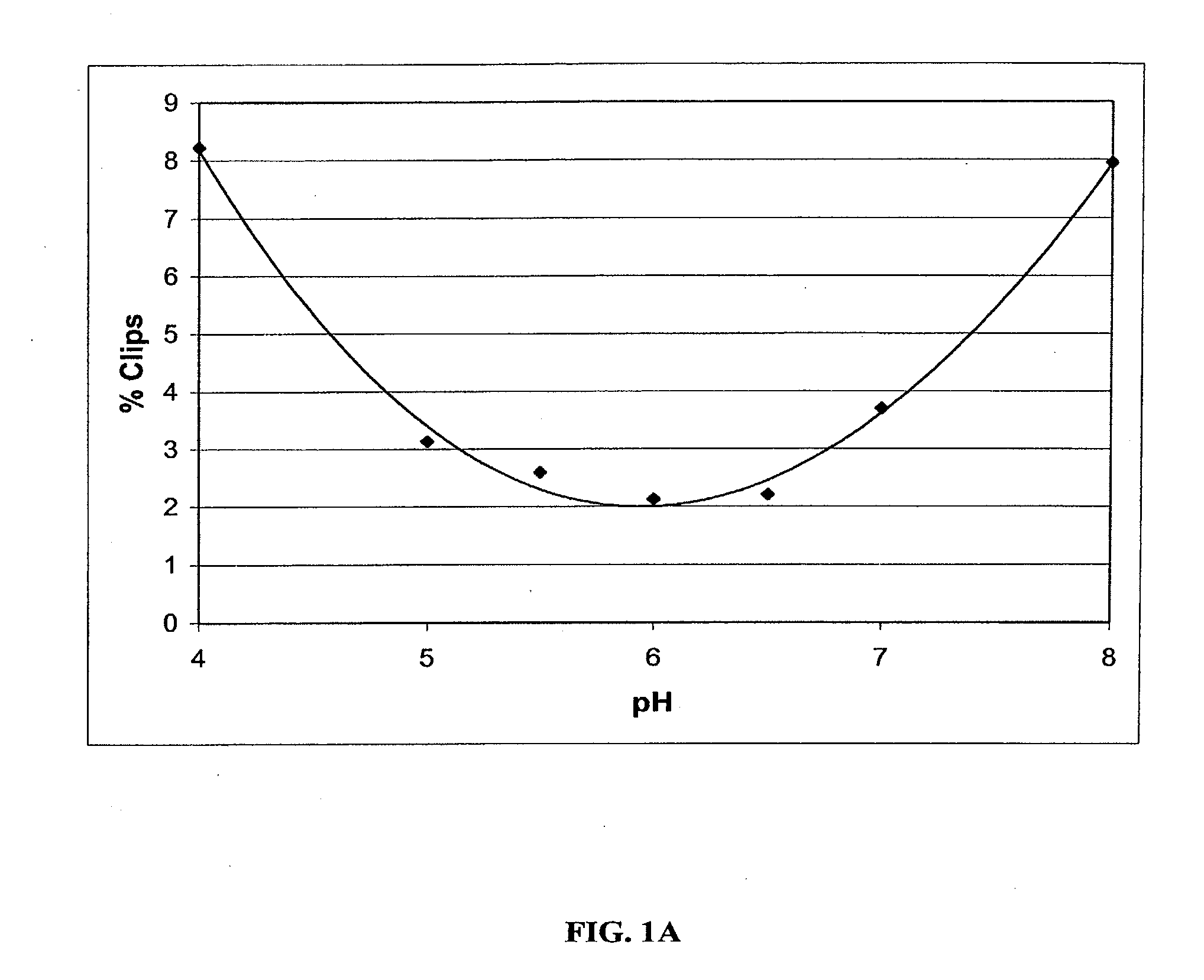

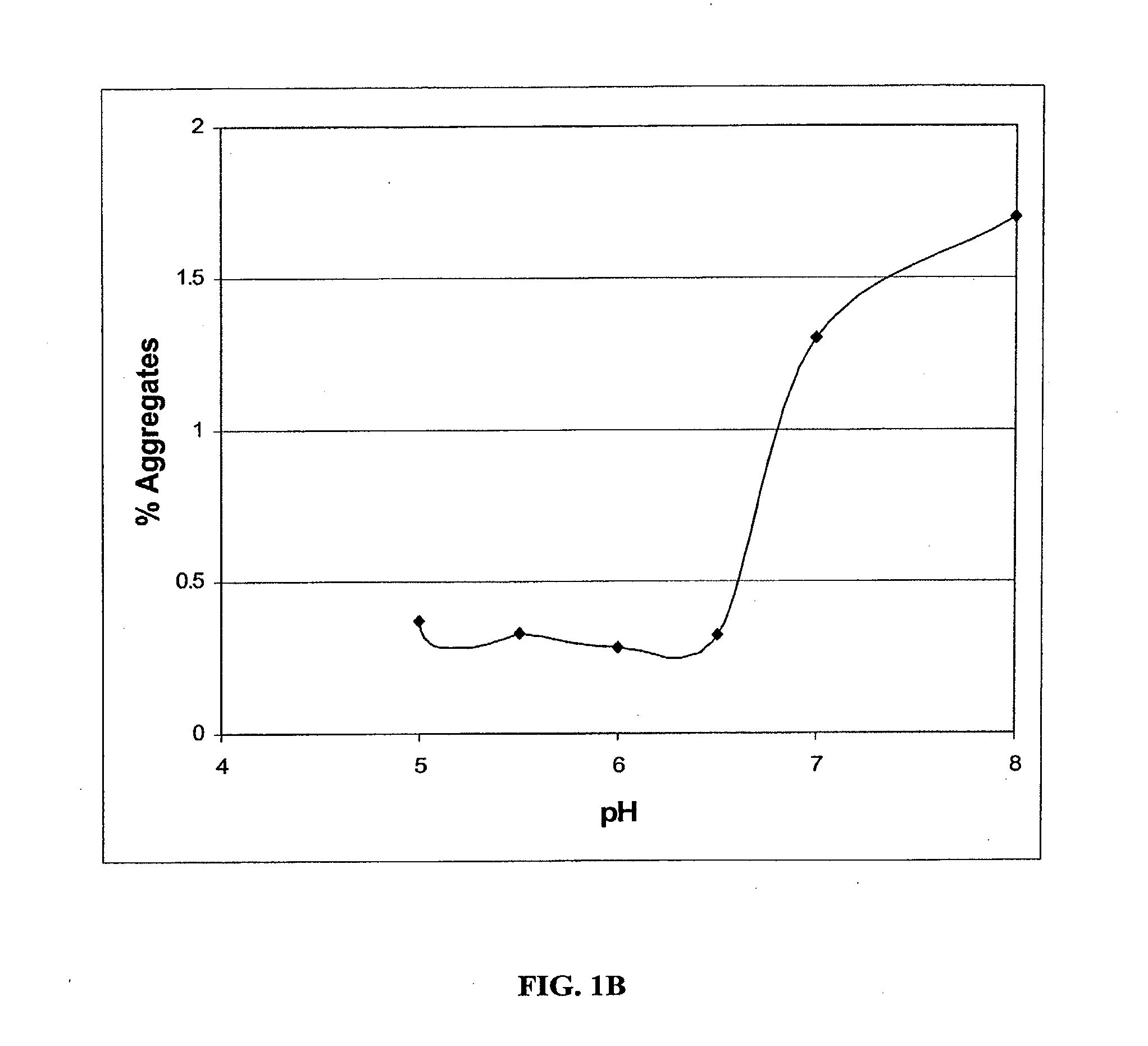

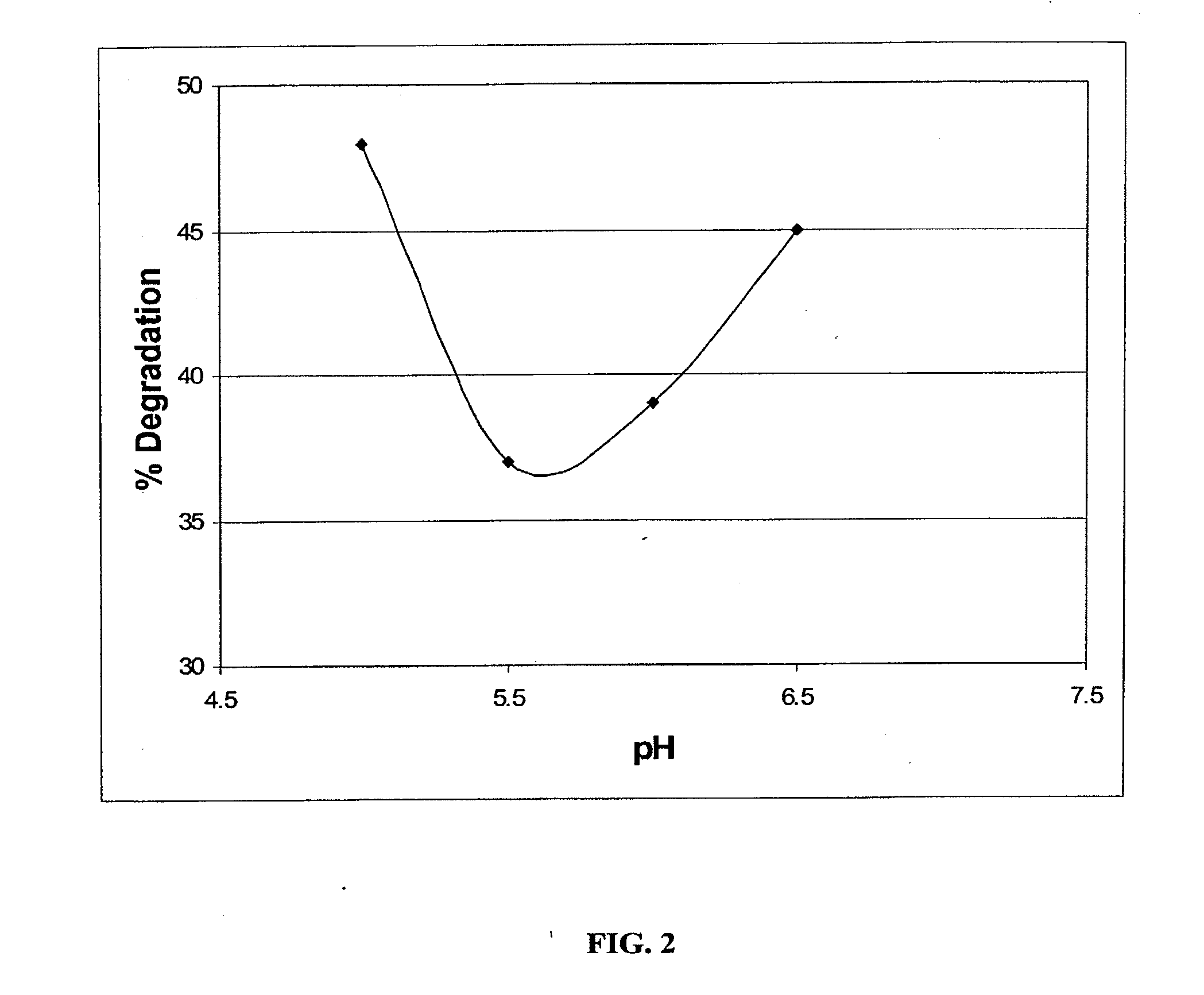

Optimization of pH

[0054]To identify the optimum formulation for pH range and to identify major degradation pathways, a pH profile study was conducted. Sample formulations contained 5.0 mg / ml anti-IL2 receptor antibody (Daclizumab) in one of three buffers: 50 mM sodium acetate buffer at pH 4.0 or 5.0, 50 mM histidine at pH 5.5, 6.0, or 6.5, or 50 mM sodium phosphate buffer at pH 7.0 or 8.5. Independent formulations were incubated at either 5° C. or 45° C. with 100 RPM shaking for 4 weeks. The physical and chemical stability of each sample was assessed at 0 and 4 weeks by analytical methods including: pH and visual analysis, UV spectroscopy at 340 nm, size exclusion chromatography (SEC-HPLC), fluorescence spectroscopy, dynamic light scattering (DLS), differential scanning calorimetry (DSC), Promega IsoQuant Assay, capillary isoelectric focusing (cIEF), SDS-PAGE (reduced and non-reduced), and bioactivity assessments (ELISA).

[0055]SEC-HPLC performed on samples after four weeks of incuba...

example 2

Optimization of Buffers

[0059]In this experiment, independent formulations contained 5.0 mg / ml Daclizumab antibody in 50 mM sodium succinate, pH 6.0; and 50 mM histidine, pH 6.0, with and without N2 gassing. Sodium citrate buffer was not included because of reports of pain on subcutaneous injection. The bioactivity (potency) at time 0, and after 4, 8, and 12 weeks of incubation at 37° C. was measured by ELISA using microplates coated with recombinant human IL2 alpha receptor (IL-2 sRα) antigen, and goat anti-human IgG-HRP conjugate.

[0060]FIG. 4 shows the effect of different buffers over time on potency following incubation at 37° C. Highest stability of the antibody formulation was achieved through 8 weeks with 50 mM sodium succinate buffer at pH 6.0. Formulations in histidine alone rapidly (less than 8 weeks) lost their potency as the buffer oxidized. Potency of the formulation remained greater than 80% for at least 12 weeks in either sodium succinate buffer or histidine buffer gass...

example 3

Screening of Excipients

Objectives

[0061]This study was conducted to screen various excipients for the formulation of Daclizumab antibody at 50 mg / mL. From the pH optimization study conducted earlier (Example 1), the formulation stability was maximized in the pH range of 6.0-6.5. Therefore in this study, excipients were screened in two buffers; 50 mM phosphate, pH 6.5 and 50 mM succinate, pH 6.0. The stability of antibody was monitored in the two buffers for 3 weeks at 5° C. and 45° C. with shaking at 100 RPM at a concentration of 50 mg / mL. The excipients examined included: surfactants (Tween 80® and Tween 20®), salts (NaCl and MgCl2), antioxidants (EDTA and methionine), amino acids (glycine, lysine, serine and proline), and co-solvents (glycerol and ethanol). Various analytical techniques (clarity, pH, SEC-HPLC, UV-Vis, and cIEF) were used to characterize the excipient-containing formulations.

[0062]The Daclizumab antibody was in a 67 mM sodium phosphate formulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com