Planar optical waveguide element, chromatic dispersion compensator, optical filter, optical resonator and methods for designing the element, chromatic dispersion compensator, optical filter and optical resonator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

reference example 1

[Reference Example 1 of a Chromatic Dispersion Compensator]

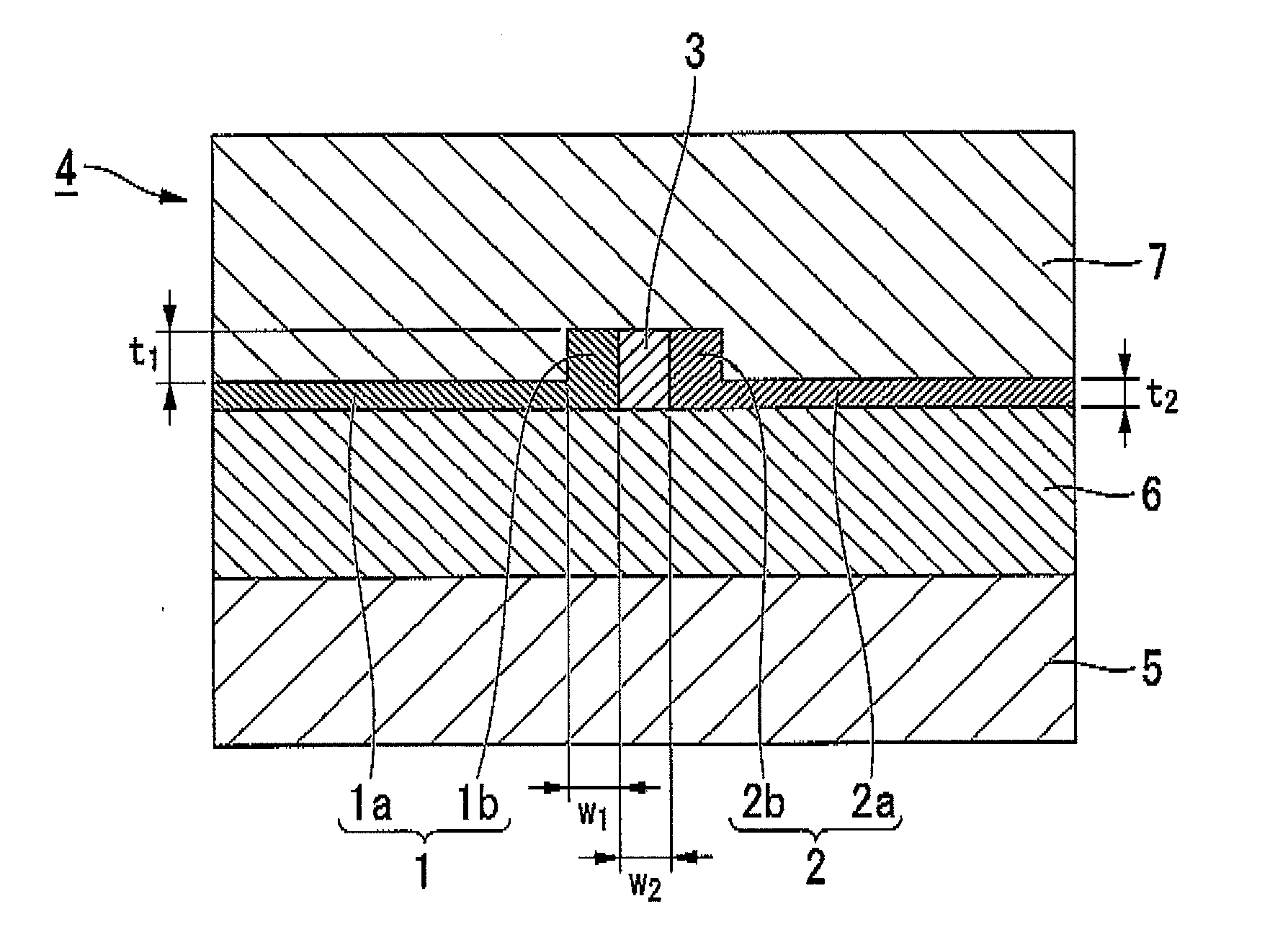

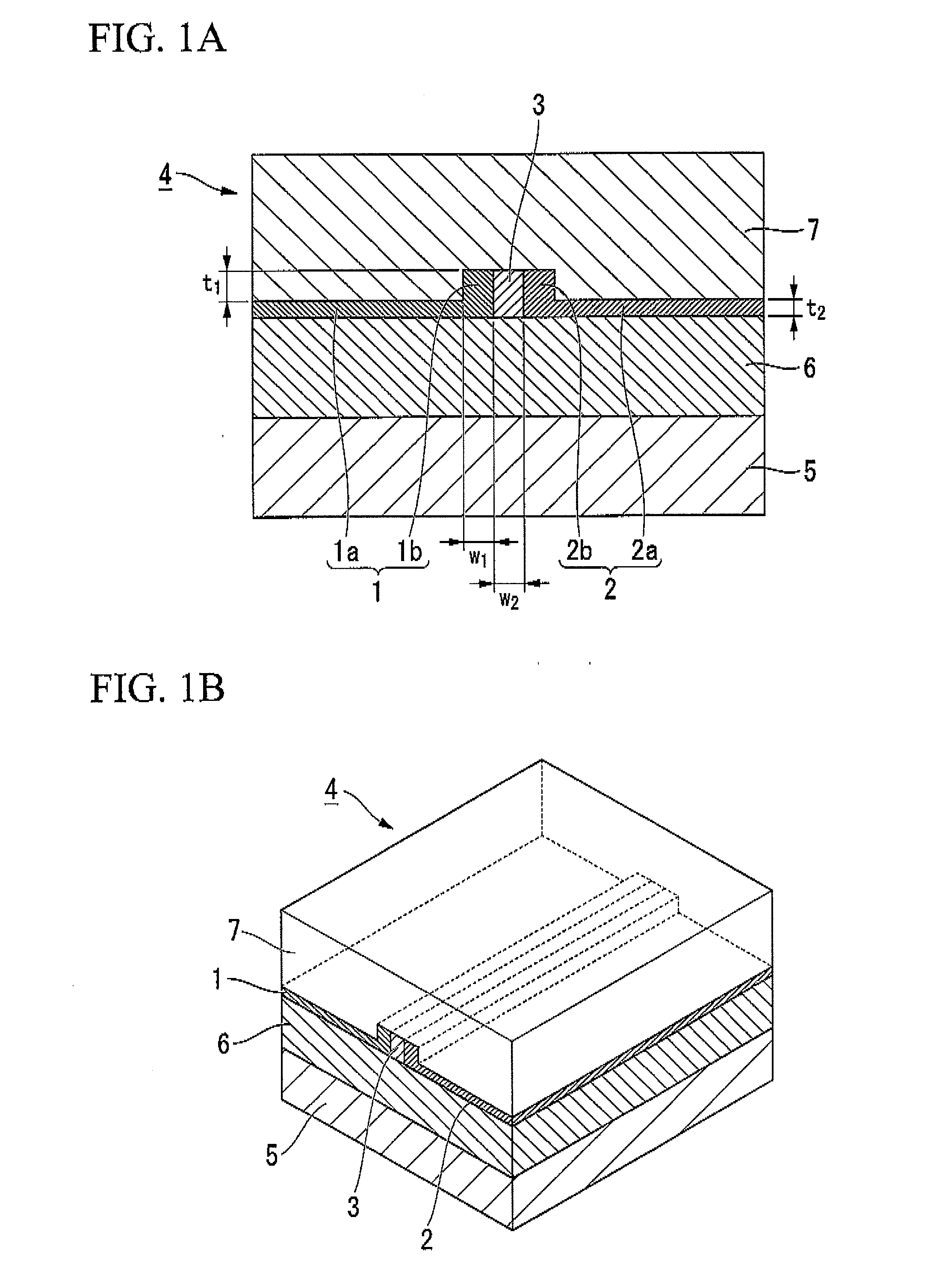

[0224]In the present reference example, a case was calculated as Reference example 1 relating to a chromatic dispersion compensator in which, in an optical waveguide structure having the composite core shown in FIG. 15 (having no center gap), the first and second ribs 31 and 32 were formed from Si, the outer side core 34 was formed from SixNy, the substrate 35 was formed from Si, the bottom cladding 36 was formed from SiO2, the top cladding 37 was formed from SiO2, and in which t1=250 nm, t2=50 nm, w1=100 nm, w2=160 nm, tout=600 nm, and tin=100 nm, and in which the thickness of the bottom cladding 36 was 2000 nm, and the maximum thickness of the top cladding 37 was 2000 nm.

[0225]In this Reference example 1 as well, in the same way as in Example 1, changes in wout and win relative to the effective refractive index were calculated in accordance with Step [1]. The results thereof are shown in FIG. 16. In this Reference example ...

example 2

[Example 2 of an Optical Filter]

[0277]The present example is an example of the design of a beam splitter having a power reflectance of approximately 40%. A beam splitter can be used in applications to split the signal light of each channel into two paths.

[0278]The design method of this beam splitter is performed in the same way as that performed for the optical filter of Example 1, other than the power reflectance parameters being altered.

[0279]The design steps of the present example as well comprise four steps in the same way as in Example 1. The same correspondence relationship between the effective refractive index and win and wout in Step [1] as that of Example 1 is used here. In Step [2], the absolute value of the field reflectance is set to 0.64 (i.e. 64%) such that the power reflectance within the reflection band of each channel, becomes 0.4 (40%). The chromatic dispersion in the reflection band of each channel is set to zero. The optical characteristics specified for the opt...

example 3

[Example 3 of an Optical Filter]

[0281]The present example is an example of the design of an optical filter having a single reflection band. The design steps are the same as in Examples 1 and 2. The power reflectance of the reflection band is set to approximately 90%. The correspondence relationship between the effective refractive index and win and wout is identical to Examples 1 and 2. The specified optical characteristics are shown in FIG. 36. The spectrum width of the reflection band is 0.01 THz.

[0282]The effective refractive index distribution derived based on the inverse scattering problem solution using these optical characteristics is shown in FIG. 37 and FIG. 38. The results obtained when the effective refractive index is converted to a square-like shaped profile are shown in FIG. 39. The optical filter of the present example can be used to extract signal light of a single specific channel as reflected light.

[0283]Note that the spectrum width of the reflection band is not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com