Roof mounting bracket for photovoltaic power generation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

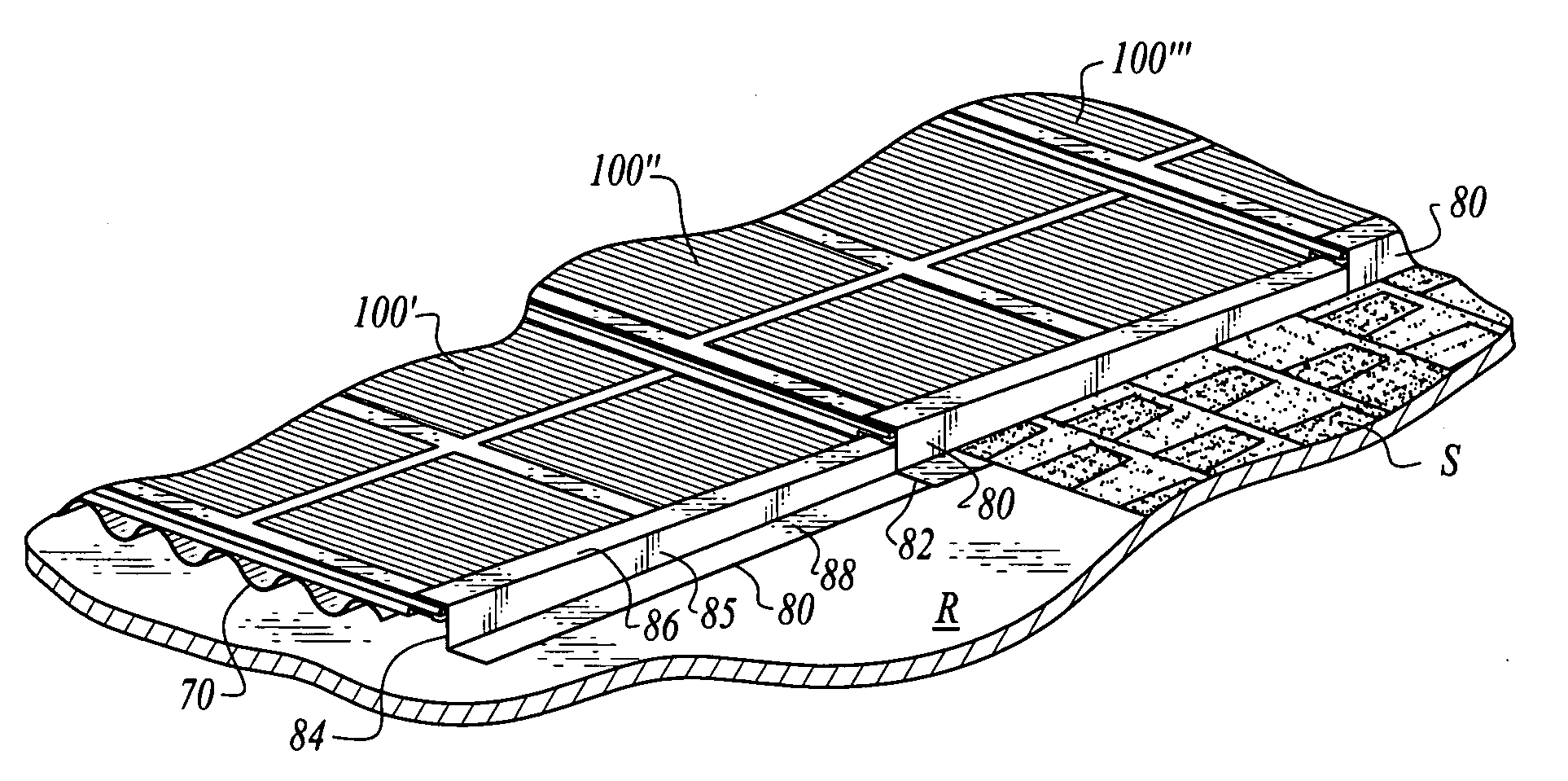

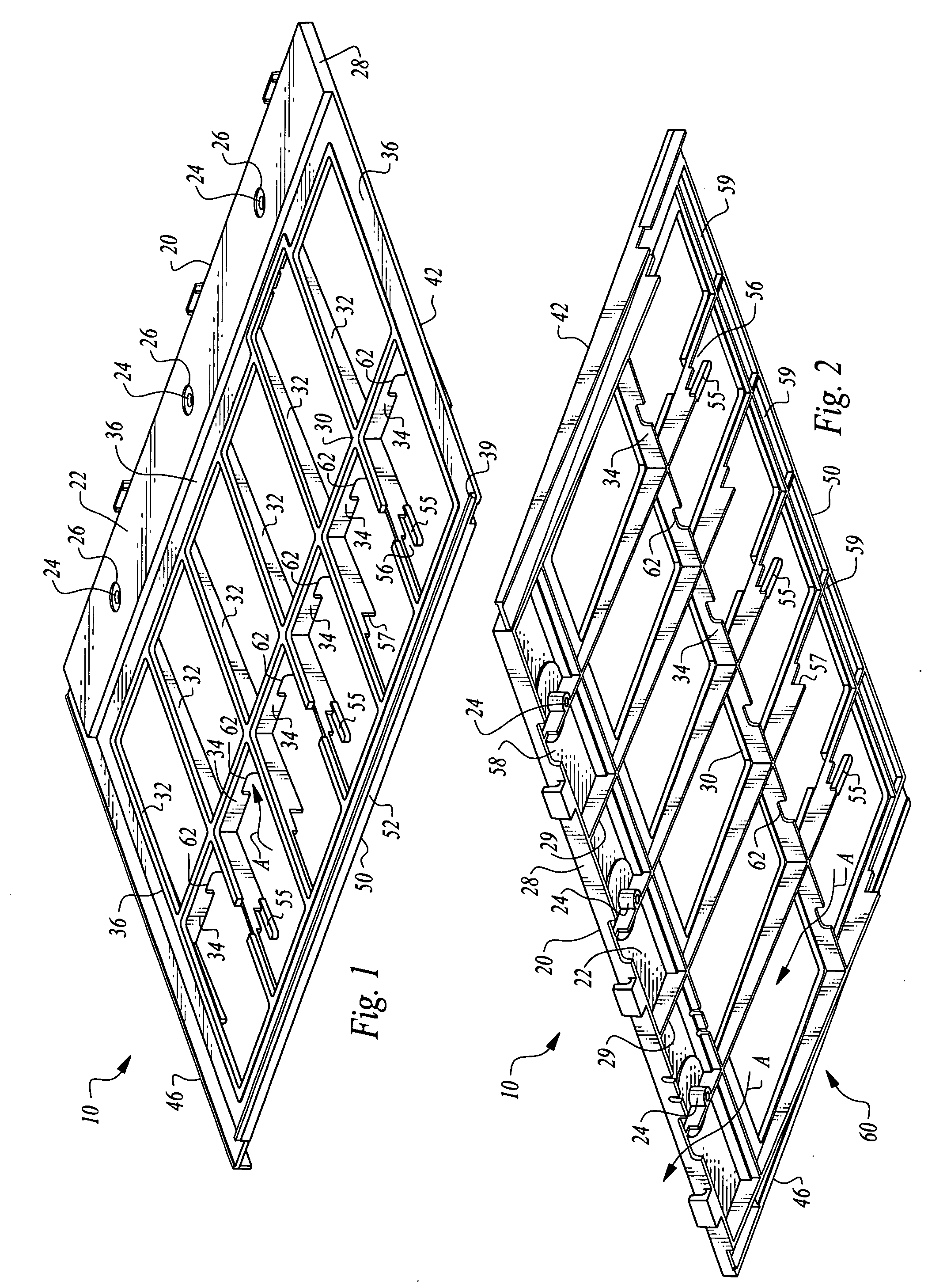

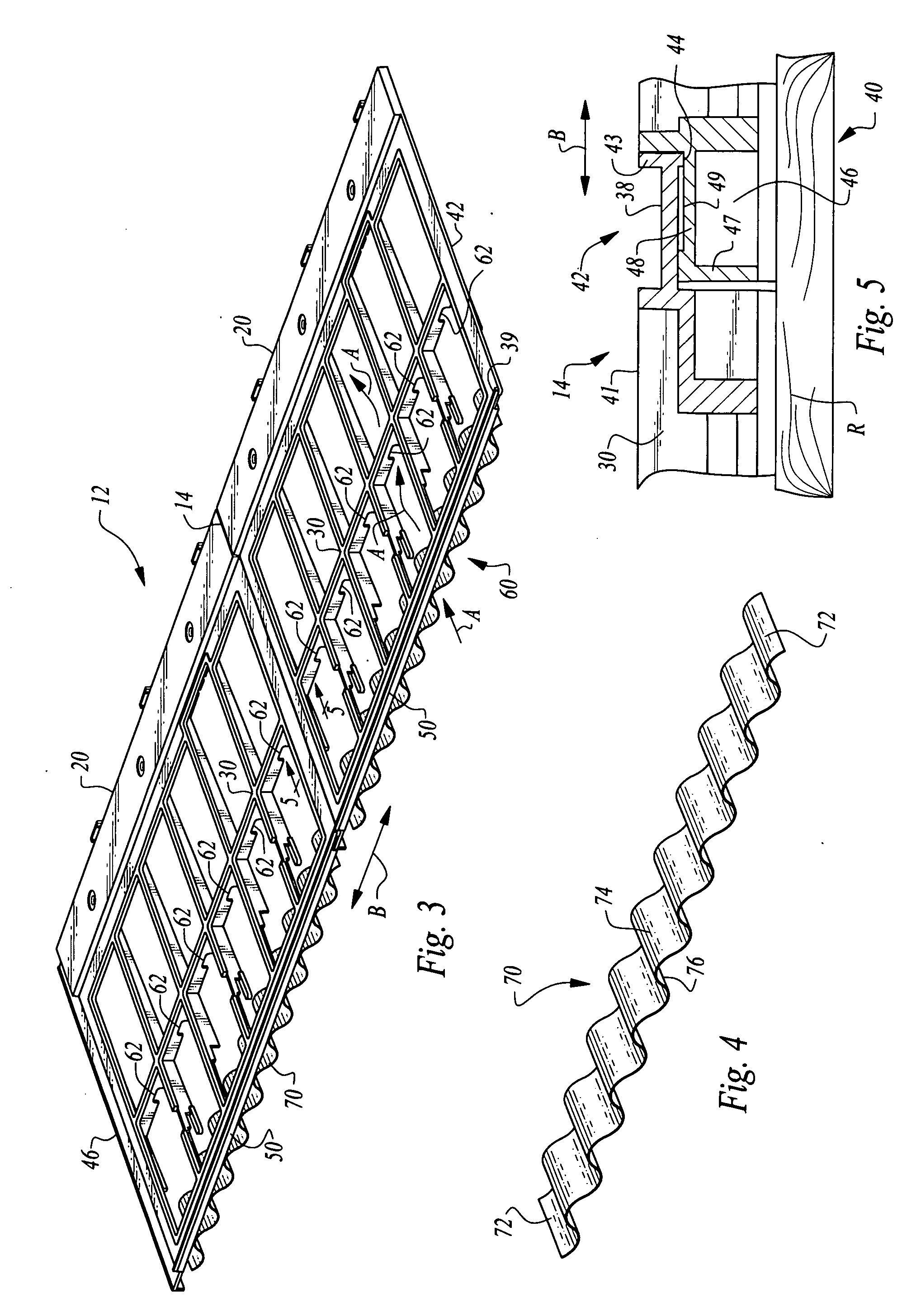

[0052]Referring to the drawings, wherein like reference numerals represent like parts throughout the various drawing figures, reference numeral 10 is directed to a bracket (FIGS. 1 and 2) for a roof mounted photovoltaic power generation system. The brackets 10 are provided in pairs 12 (FIG. 3) which together support a photovoltaic cell 102 stack assembly to form a panel 100 (FIG. 9). The panel 100 can act similar to a shingle S (FIG. 13) upon the roof R to shed water and protect structural portions of the roof. The brackets 10 interlock together laterally and vertically while accommodating airflow therebeneath for cooling. The brackets also accommodate thermal expansion and have edge details to facilitate airflow and to provide water preclusion. The brackets are also configured to facilitate interconnection of an electric subsystem 110 for combining adjacent panels 100 together as part of the overall photovoltaic power generation system.

[0053]In essence, and with particular referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com