Method and apparatus for accelerated wear testing of aggressive diamonds on diamond conditioning discs in cmp

a technology of aggressive diamonds and conditioner discs, which is applied in the direction of abrasive surface conditioning devices, lapping machines, manufacturing tools, etc., can solve the problems of deterioration of the performance of the diamond conditioner disc with use, no simple, reliable, cost effective method to measure the number of active diamonds, and the highest degree of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

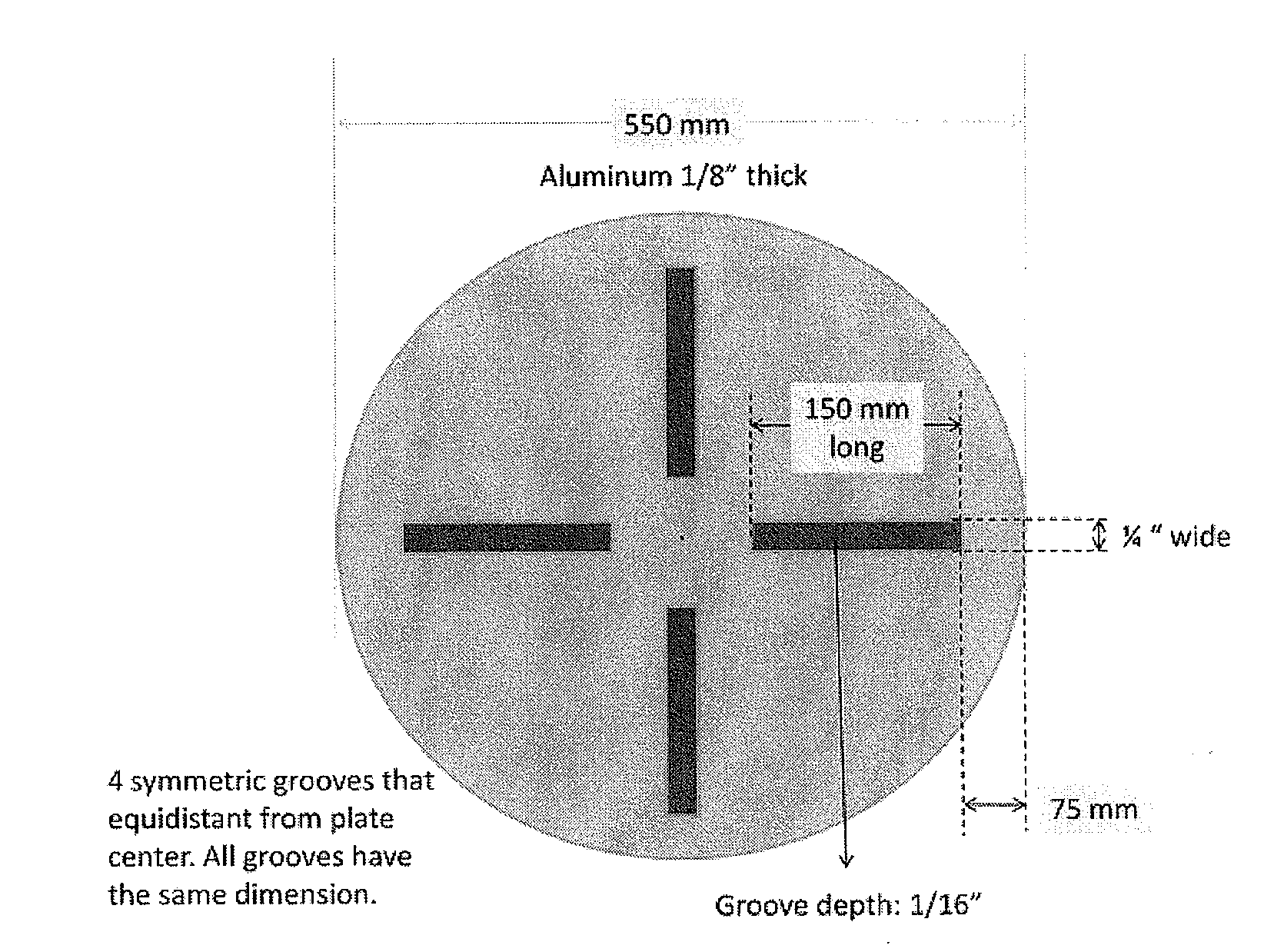

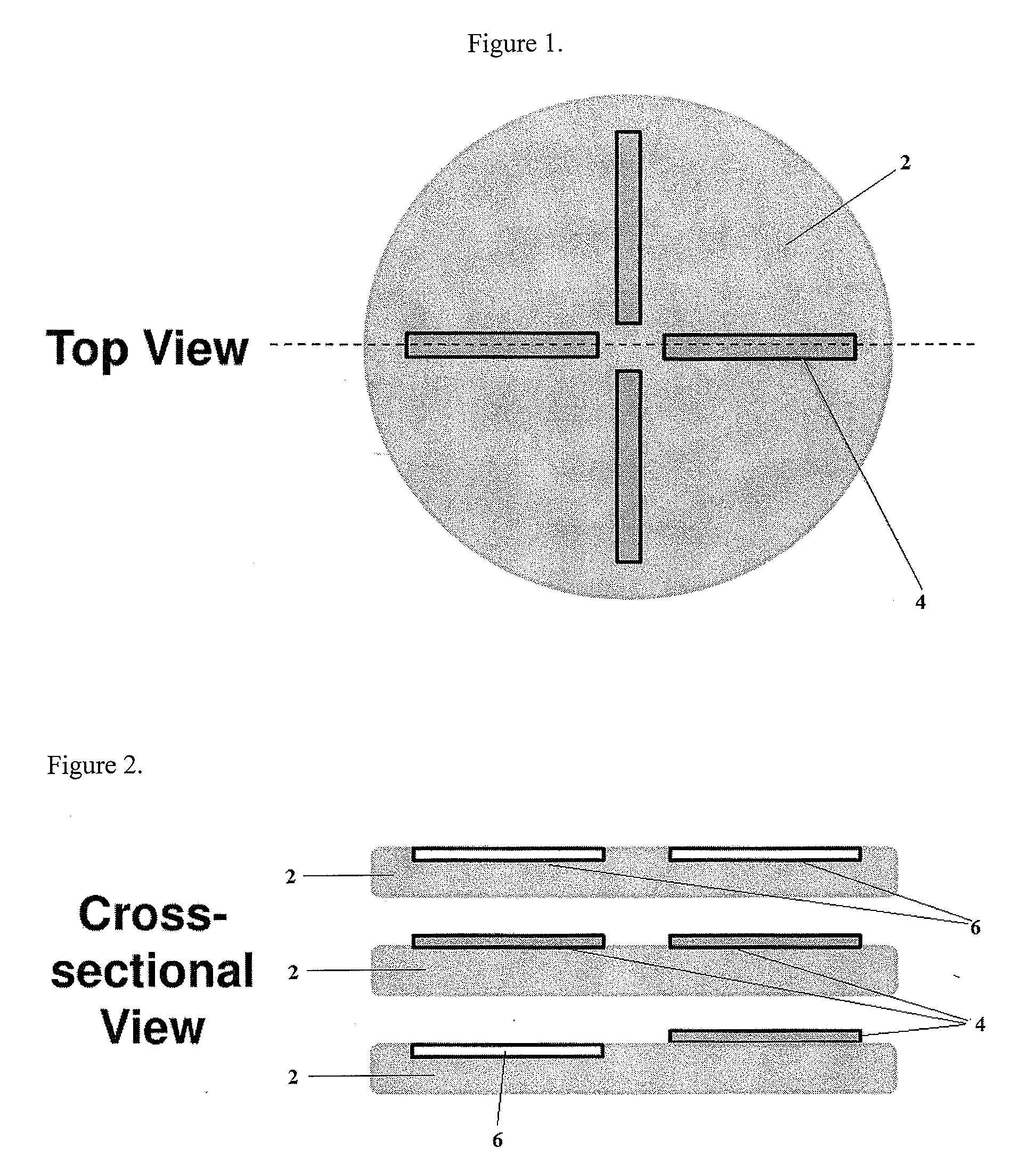

[0048]An aluminum disc 550 mm in diameter and ⅛th inch thick was prepared from aluminum sheet by cutting and in the upper surface of the disc 4 grooves were cut ¼ inches wide and 150 mm long starting 50 mm from the center of the disc and heading out radially at right angles to each other to end 75 mm short of the edge of the disc. The grooves were cut with a cutting tool to a depth of 1 / 16th inch.

[0049]The disc was attached, grooves facing up, to the top of the platen of an APD 500 polishing tool using adhesive paper. The top ten aggressive diamonds determined by scratch furrow area as measured by profilometer on a Mitsubishi Materials Corporation Triple Ring Dot diamond conditioner disc (MMCTRD) were identified using the method of U.S. patent application Ser. No. 12 / 359,772 and observed by scanning electron microscope as shown in the before column in FIG. 7. The diamond conditioner disc was attached to the CMP tool which was then operated with the platen rotating at 50 RPM, the dia...

example 2

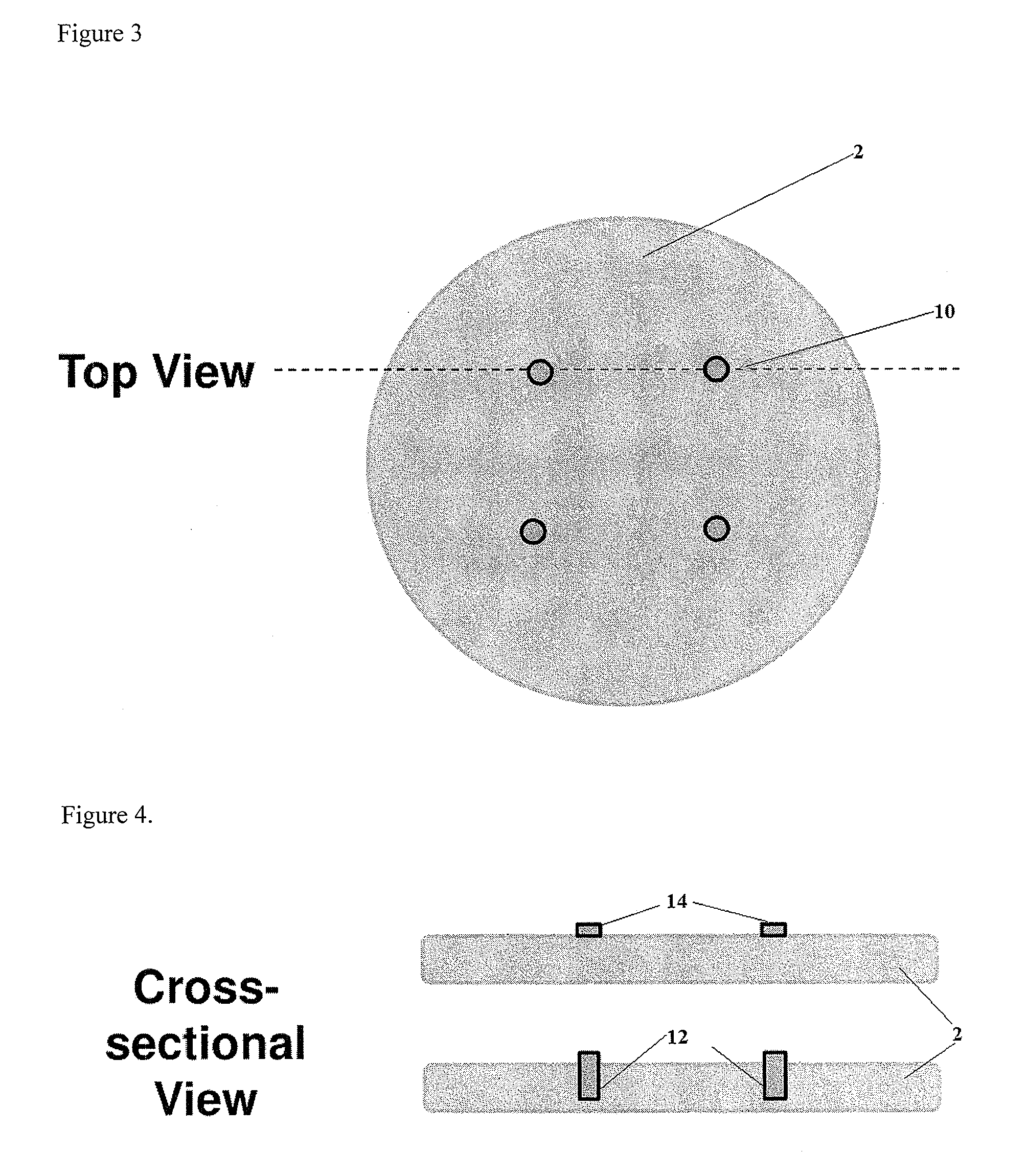

[0051]A polycarbonate disc made from polycarbonate sheet and having the same dimensions as the aluminum plate in Example 1 was prepared and 4 holes halfway between the center and edge of the disc on lines at ninety degree intervals were drilled at ⅙th inch diameter as shown in FIG. 8. The depth of the holes was 3 / 32nds inch, the length of the studs, which were aluminum, was ⅛ inch, the studs were made fast with adhesive and allowed to protrude 1 / 32nd of an inch above the surface of the disc.

[0052]Except for the use of this disc, precisely the same procedure was used as in Example 1 and before and after scanning electron microscope photographs of the top ten aggressive diamonds in FIG. 9 shows 3 pulled and 4 fractured aggressive diamonds when observed by scanning electron microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com