Intercalated Superlattice Compositions and Related Methods for Modulating Dielectric Property

a superlattice composition and intercalation technology, applied in water-setting substance layered products, transportation and packaging, chemistry apparatus and processes, etc., can solve the problems of prohibitively excessive power consumption, semiconductor carrier mobility, and art remains somewhat lacking, so as to simplify device design and performance enhancement, increase the dielectric and/or capacitance properties of self-assembled organic components, and increase the k value of the dielectric composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

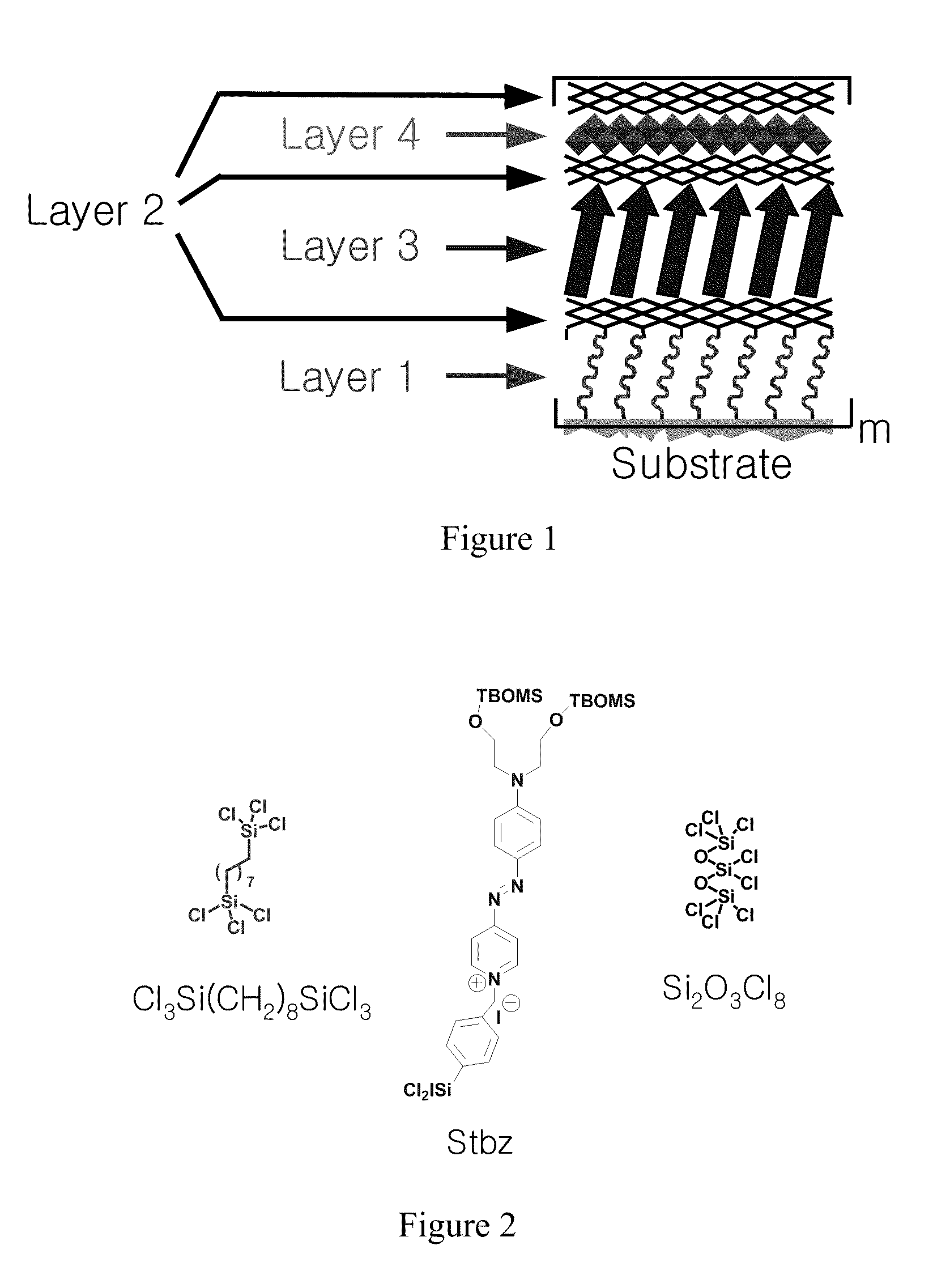

[0051]Materials. The Cl3Si(CH2)8SiCl3, octachlorotrisiloxane, and metal alkoxide reagents are commercially available, whereas the Stbz stilbazonium precursor was prepared according to the literature. Native oxide coated highly n-doped silicon (100) wafers were purchased from Montco Silicon Tech, Spring City, Pa. ITO-coated glass substrates (20 Ω / sq; 20-30-Å rms roughness) were purchased from Donnelly Corp and cleaned according to known procedures [P. Zhu et al., Chem. Mater. 14, 4982 (2002)]. Pentacene was purchased from Aldrich and purified by gradient vacuum sublimation before use. All self-assembly procedures were performed in an N2-filled glove bag. Structures of reagents useful in such self-assembly process as shown in FIG. 2. Various other reagents and component precursors are found in the aforementioned references.

example 2

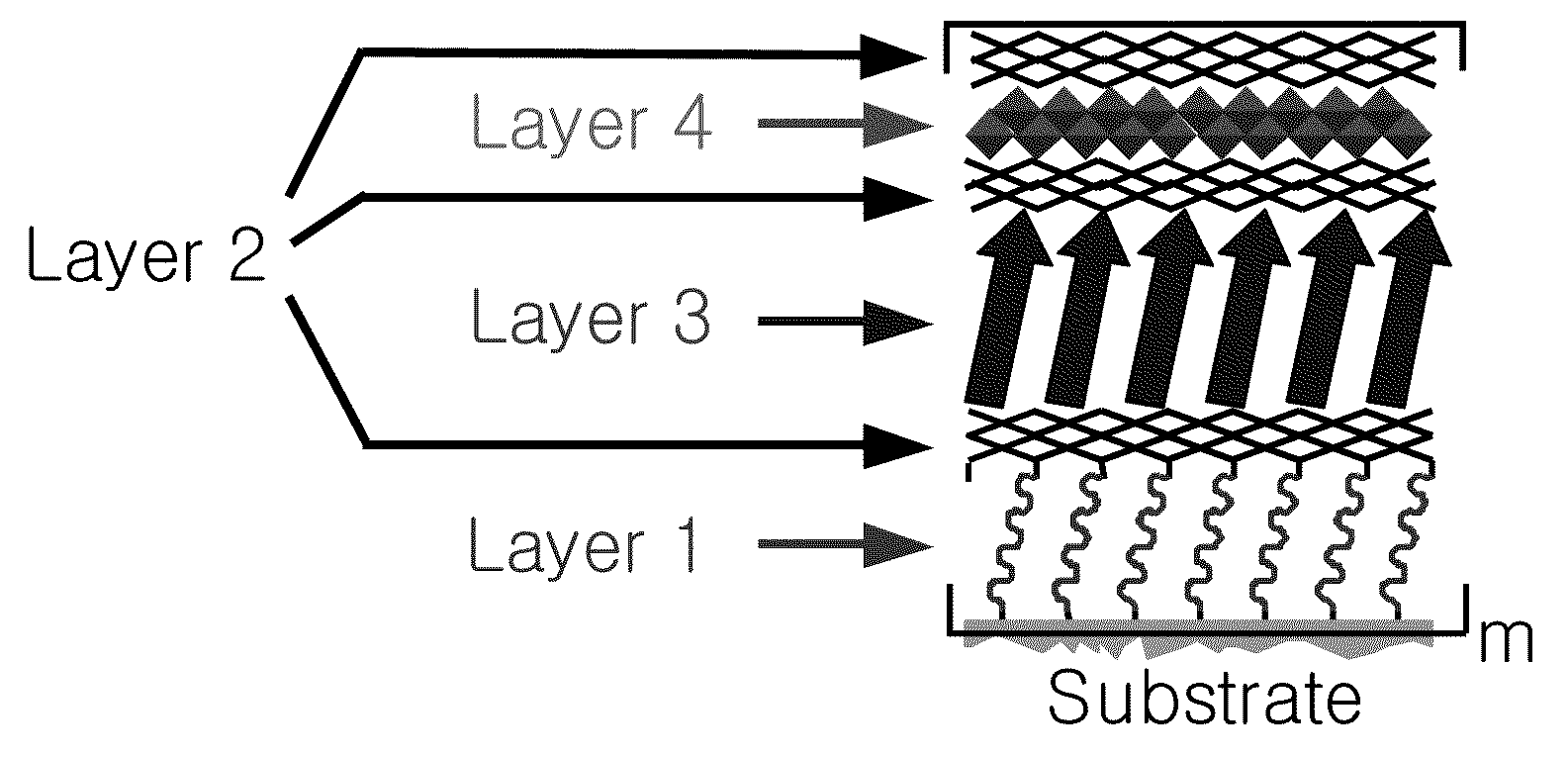

[0052]Growth of SAS dielectrics. With reference to FIG. 1: Layer 1. Silicon or ITO substrates were loaded into a Teflon sample holder and immersed in a 5 mM toluene solution of Cl3Si(CH2)8SiCl3 at 0 C; after 1 h the substrates were rinsed twice with toluene and then sonicated in acetone-H2O (95-5 v:v) solution for 3 min. The substrates were then dried at 115° C. for ˜5 min. Layer 2. The substrates were immersed in a dry pentane solution of Si3O2Cl8 (34 mM) for 30 min, washed twice with dry pentane, sonicated in acetone for 15 min, and dried at 115° C. for ˜5 min. Layer 3. The substrates were immersed in a dry THF solution of Stbz chromophore precursor shown (1-2 mM) for ≧15 min at 60° C. After cooling to 25° C., the substrates were washed with toluene and THF, sonicated in acetone for 5 min., and dried at 115° C. for ˜5 min. Layer 4. The substrates were immersed in a freshly prepared dry THF solution of metal alkoxide (M=Ti, Zr, Hf; 1.0 mM) for 1-2 h, washed twice with dry THF, wash...

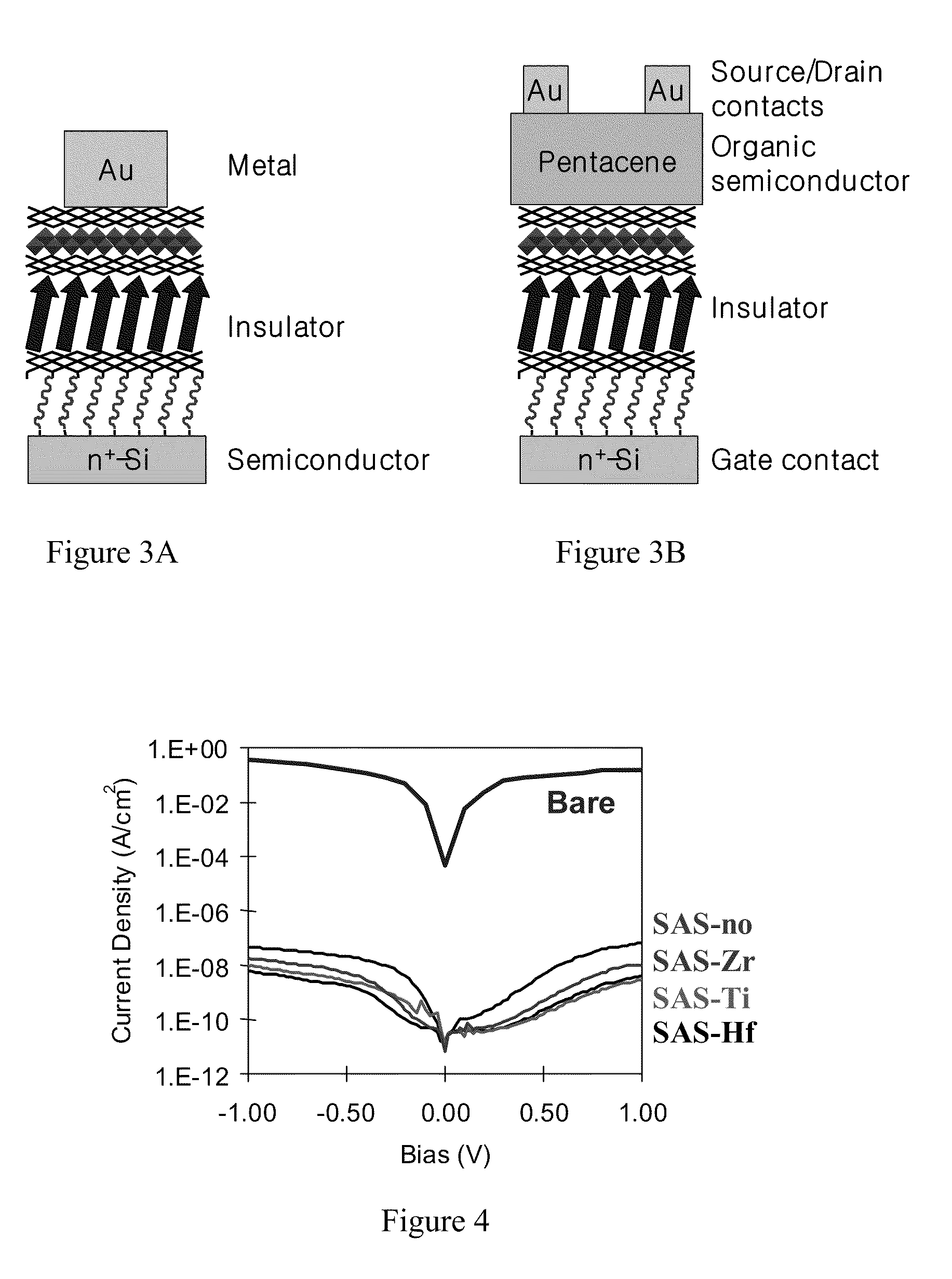

example 3

[0053]Device fabrication. For OTFTs, pentacene was vacuum deposited at ˜2×10−6 Torr (500 Å, 0.2 Å / s) while maintaining the substrate-nanodielectric temperature at 60° C. Gold electrodes for OTFT / MIS devices were vacuum-deposited through shadow masks at 3-4×10−6 Torr (500-1000 Å, 0.5 Å / s).

PUM

| Property | Measurement | Unit |

|---|---|---|

| current densities | aaaaa | aaaaa |

| current densities | aaaaa | aaaaa |

| frequencies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com