Packaging systems for the control of relative humidity of fresh fruits, vegetables and flowers with simultaneous regulation of carbon dioxide and oxygen

a technology of relative humidity and packaging system, applied in the field of new packaging system, can solve the problems of affecting product quality and food safety, affecting the quality of products and vegetables picked immaturely, and not being availabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

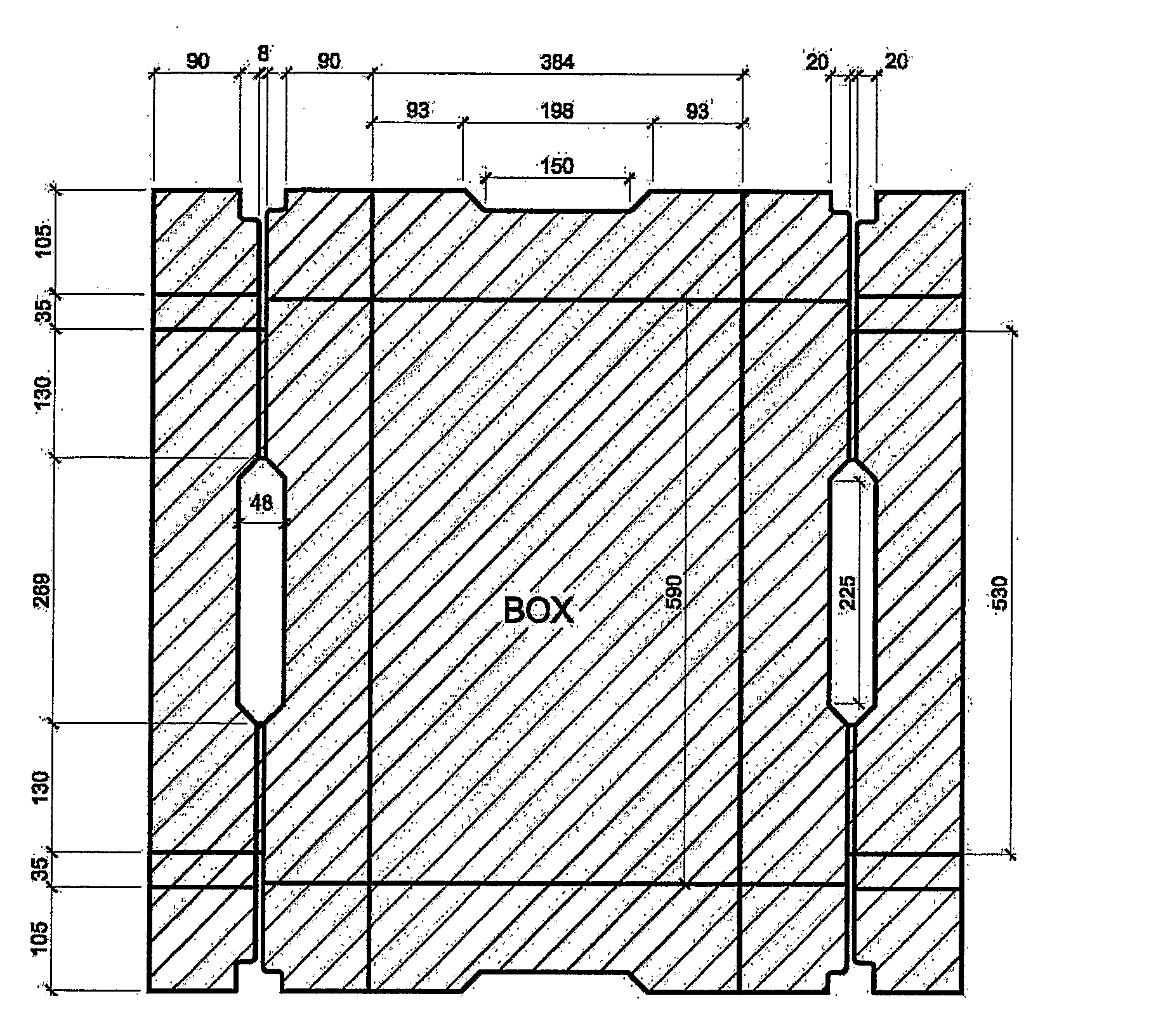

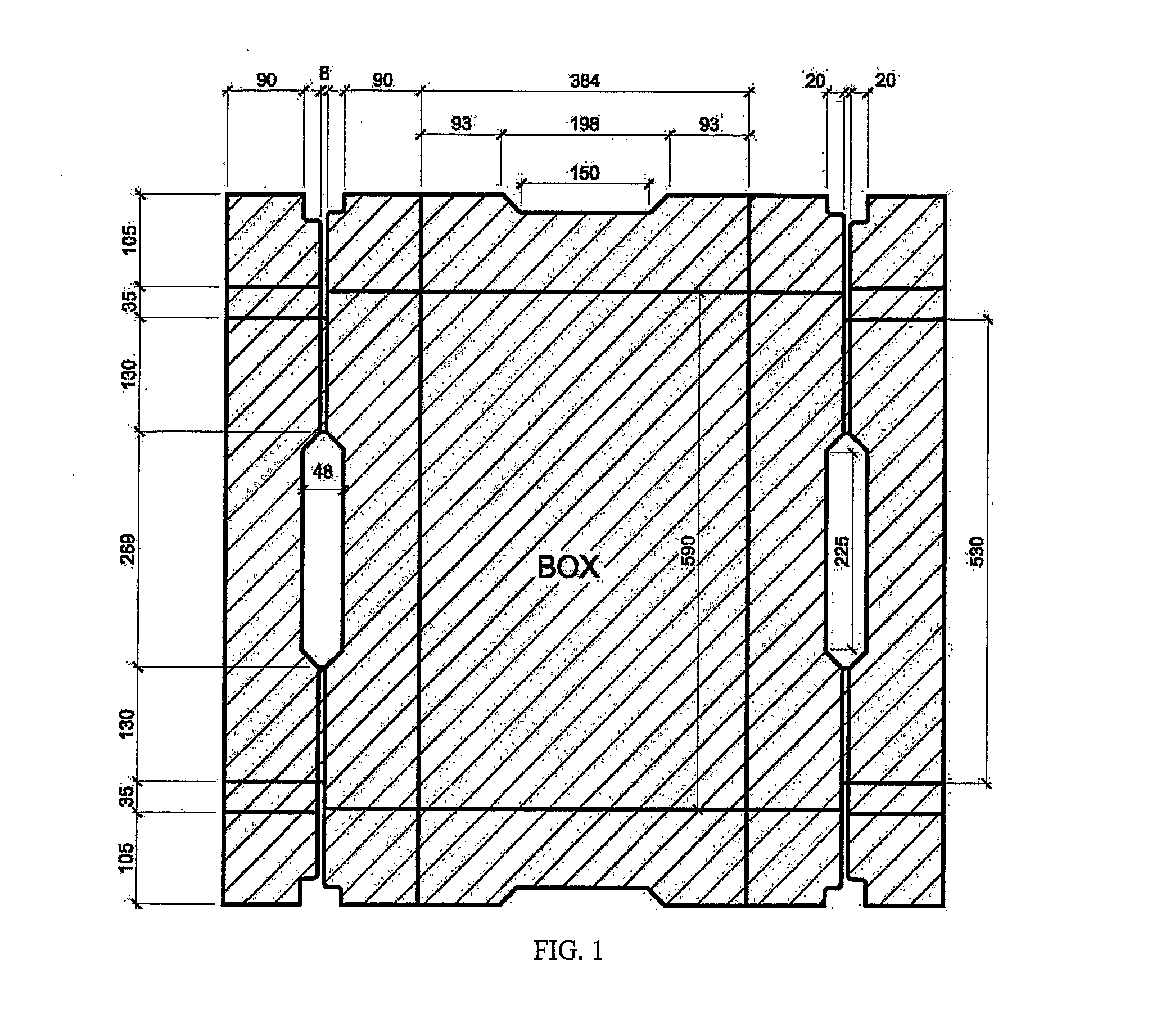

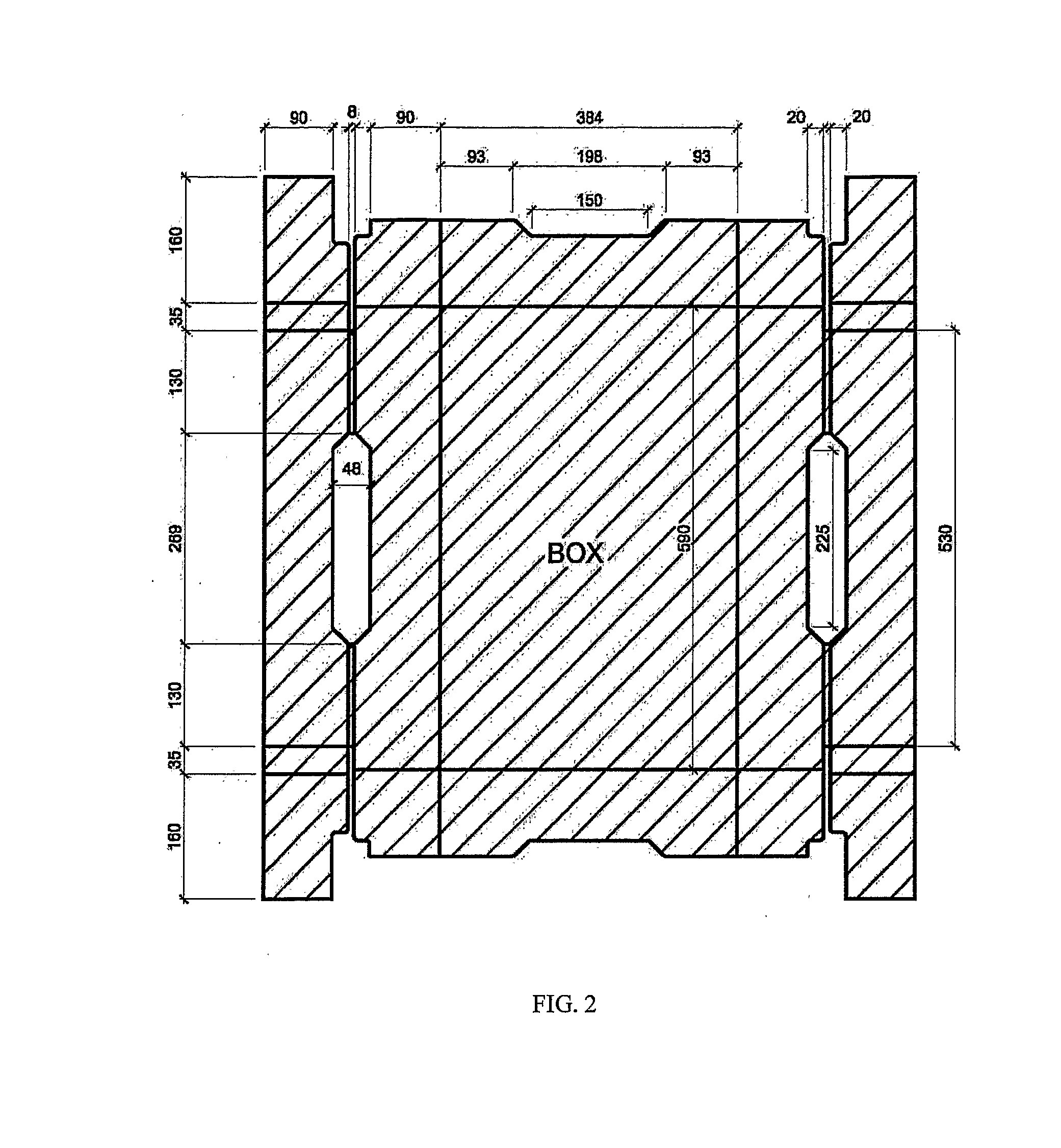

Image

Examples

example 1

[0090]The process for preparation and preservation of fresh peaches (cv. Red Haven) using the invention, involves the following:[0091]1. Fresh peaches were harvested at a full ripe maturity indicated by a lack of chlorophyll in the ground cover of the flesh with a firmness of 4 to 6 kg-f fruit firmness;[0092]2. The fruit were sanitized with a 100 ppm solution of chlorine, dried, cooled to 1° C. and packed in the described container constructed with 30 g per m2 nylon 6 / 12 laminate with oxygen transmission rate 5000 cm3 per m2 per 24 hours at 25° C. at 1 atm as created with 10 microperforations in a container containing 9 kg of fresh peaches. Oxygen atmospheres were maintained between 2 and 3% oxygen while carbon dioxide atmospheres were maintained at 5% to 6%;[0093]3. A control sample of peaches of the same maturity was placed in a similar modified atmosphere package maintained at 94% RH to 100% RH;[0094]3. Peaches in the control and those stored in the invention were held at 1° C. f...

example 2

[0097]The process for preparation and preservation of perishable kiwi fruit using the invention, involves the following:[0098]1. Ready-to-eat firm mature ripe kiwi fruit (cv. Hayward; firmness of 3 to 5 kgf) that are free of obvious decay are selected, washed with or 100 ppm chlorine if available and dried;[0099]2. Kiwi fruit are packed in preformed trays composed either of wood fibre or plastic (wood fiber is preferred) and placed in the container;[0100]3. The kiwi fruit are cooled to 0° C. and the container is sealed by placing the plastic top in place with the desired sealant;[0101]4. The kiwi fruit were sealed in the package with microperforations sufficient to provide an oxygen transmission rate of 3000 cm3 per m2 per 24 hours at 25° C. at 1 atm and stored at 0° C. for up to 28 days.

[0102]The quality of the kiwi fruit compared to conventionally packed controls (corrugated boxes) controls demonstrated superior eating quality and freedom from decay after 28 days in the container....

example 3

[0104]The process for preparation and preservation of fresh mushrooms using the invention, involves the following:[0105]1. Fresh white mushrooms were harvested closed cap maturity;[0106]2. The fruit were washed in a fresh water cascade and dried by warm dry air to the original weigh, cooled to 1° C. and packed in the described container constructed with 35 g per m2 nylon 6 / 66 laminate with oxygen transmission rate of 30,000 cm3 per m2 per 24 hours at 25° C. at 1 atm created with 90 microperforations in a container containing 5 kg of fresh mushrooms. Oxygen atmospheres were maintained between 3 and 5% oxygen while carbon dioxide atmospheres were maintained at 7% to 10%;[0107]3. A control sample of mushrooms of the same maturity was placed in a similar modified atmosphere package maintained at 94% RH to 100% RH;[0108]4. Mushrooms in the control and those stored in the invention were held at 1° C. for periods of 5, 10 and 15 days;

[0109]Mushrooms stored in the control packages appeared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com