System for extracting hydrogen from a gas containing methane

a technology of methane and gas, applied in the direction of hydrogen separation using solid contact, sustainable manufacturing/processing, separation processes, etc., can solve the problems of comparatively small effort and expense required to achieve the carbon dioxide reduction described, and achieve the effect of simple and inexpensive methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

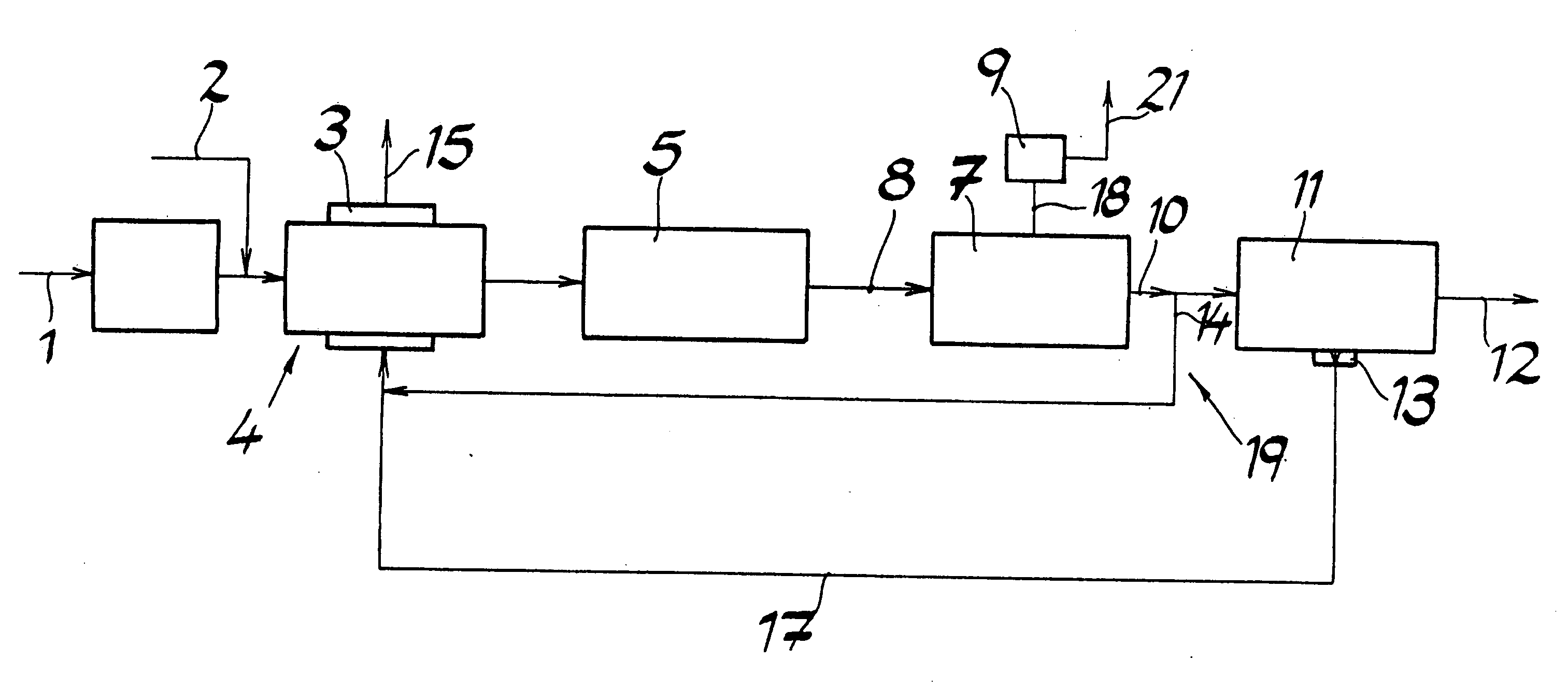

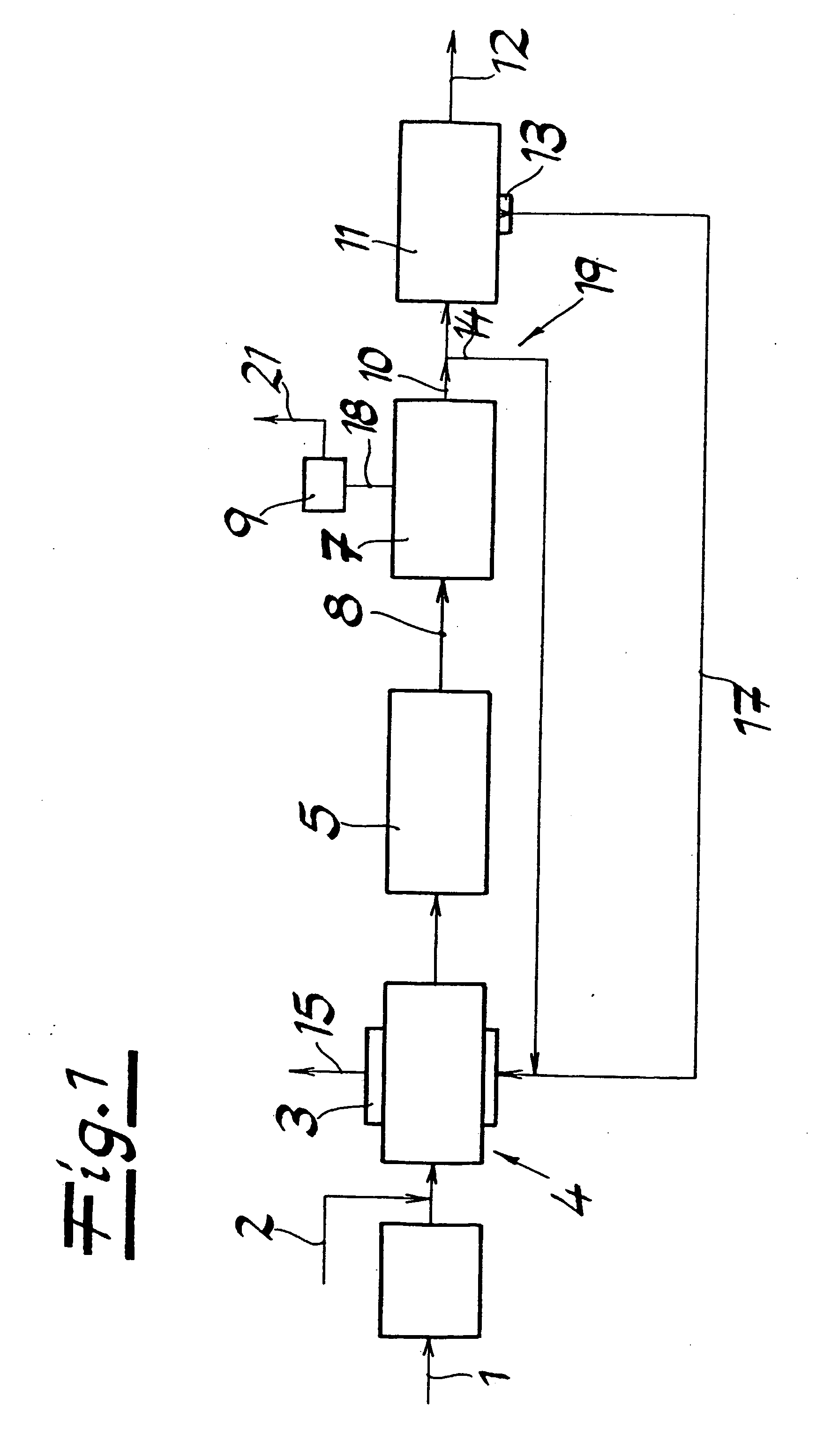

[0018]FIG. 1 shows a method according to the invention for extracting hydrogen from a natural gas that contains methane. A steam stream 2 is mixed into a natural gas stream 1. The hydrocarbons contained in the natural gas, particularly methane, are catalytically split into hydrogen, carbon monoxide, and carbon dioxide, in a reformer 4 equipped with a combustion chamber 3, using the steam stream 2 that is mixed in. This reformation takes place almost completely, so that practically no gases that contain hydrocarbons are present, any longer, at the exit from the reformer 4. In a subsequent conversion reactor 5 that is operated at medium temperature, catalytic conversion of the carbon monoxide that has formed to carbon dioxide and hydrogen takes place, using steam. This reaction also proceeds almost completely, so that the carbon monoxide content of the gas stream 8 that exits from the conversion reactor 5 is less than 1 vol.-% (dry). Subsequently, the carbon dioxide that has formed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com