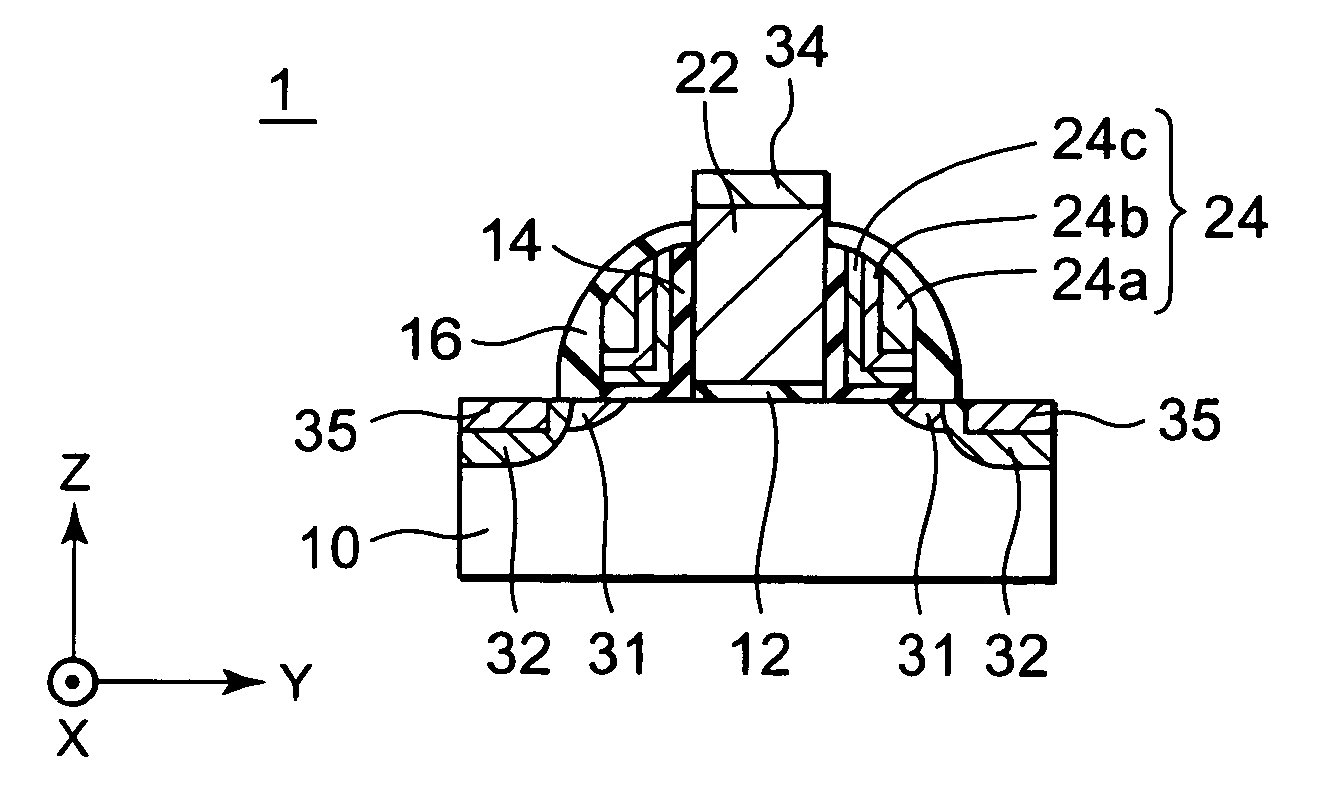

[0008]However, the present inventor has recognized the following point. Namely, the technique disclosed in JP-A-2005-228786 has the following problems. When the gate (word gate) 122 and the

diffusion layer electrodes 132 are silicided (to form the silicide

layers 134 and 135), the memory gate insulating film (charge storage layer) 114 which is the ONO film already has a section of an upper end exposed. When a silicide step is performed while the section of the ONO film is being exposed in this way, a silicide film is formed in the ONO film because nickel components attached onto the

nitride film of the ONO film are easily subjected to a silicide reaction with

silicon in the nitride film. Then, even when the excessive nickel components are removed by

etching, the silicide film is not removed, and remains on the ONO film. As a result, the silicide layer (control gate) 124 and the gate (word gate) 122 may be short-circuited due to the remaining silicide film. A technique for preventing short-circuiting between the ONO film and the control gate is desired.

[0009]Additionally, in this structure, the silicide layer (control gate) 124 which is the silicide film is in direct contact with the memory gate insulating film (charge storage layer) 114 serving as a charge storage region. That is,

nickel silicide which has an extremely

low resistance as compared to polysilicon, comes into direct contact with the ONO film. Thus, it is thought that charges stored in a nitride film of the ONO film are very easily affected by an electric state of the

nickel silicide (for example, variations in

voltage), or a state of an

oxide film (for example, uniformity in film thickness) located on the nickel silicide side of the ONO film. Thus, the electric state and the film thickness state can make the state of charges stored in the nitride film extremely unstable, and make the distribution of charges nonuniform. In particular, nickel components of the nickel silicide may be partly diffused into the

oxide film on the nickel silicide side to degrade the quality of the ONO film. In that case, the charges stored in the nitride film can be prone to penetrate the nickel components. In this way, such occurrence of unstable charges and nonuniform electrolytic distribution at the ONO film, and degradation in quality of the ONO film leads to a

crash of data, which may significantly reduce reliability and stability of a

memory cell. Thus, there is a need for a technique that prevents the

instability of charges and nonuniformity of electrolytic distribution at the ONO film and the degradation in quality of the ONO film, thereby to enhance the reliability and stability of the

memory cell.

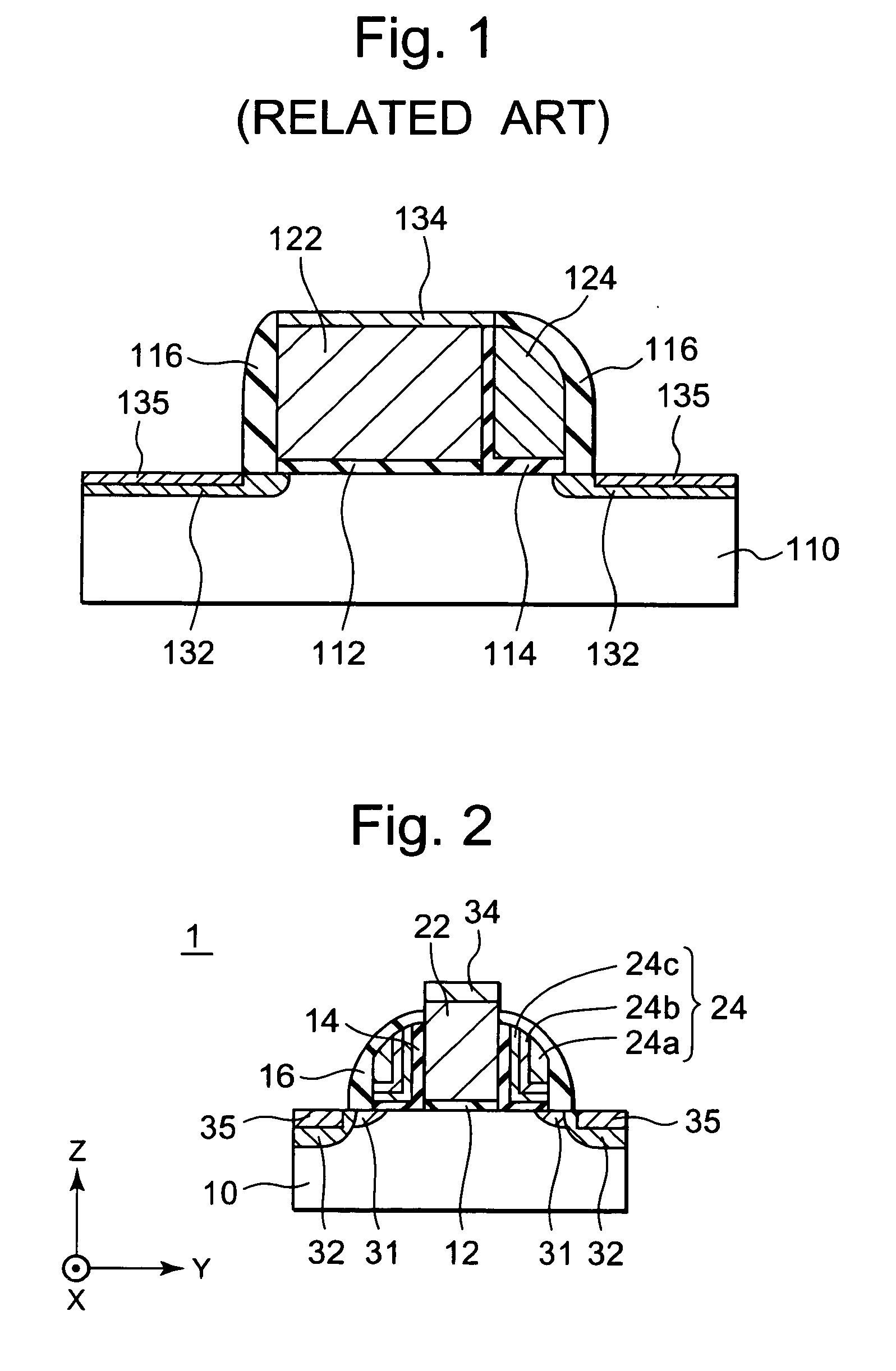

[0012]In this exemplary embodiment, the silicide layer is provided by silicide containing nickel. Therefore, the resistance of the control gate can be made lower. On the other hand, the non-silicide

layers are provided between the silicide layer and the charge storage layer, thereby separating both

layers. Thus, even when a nitride film exposed to the section of the ONO film is partly silicided, the silicide layer is spaced more apart from the word gate, which can prevent short-circuiting. The silicide layer is configured not to be in direct contact with the ONO film by a presence of the non-silicide layers. Thus, the influences of the electric state of the silicide layer, and of the state of an oxide film on the silicide layer side of the ONO film can be reduced to a much smaller level. The nickel components of the silicide layer are prevented from being diffused into the ONO film, so that the charges stored in the nitride film can be prevented from being drawn into the nickel components. Such an arrangement can stabilize more the state of charges stored in the nitride film, make the charge distribution more uniform, and prevent the degradation in quality of the ONO film. As a result, the reliability and stability of the memory

cell can be enhanced.

[0015]The invention can prevent short-circuiting between the word gate and the control gate. The

instability of charges and nonuniformity of electrolytic distribution at the ONO film, the degradation in quality of the ONO film, and the like can be prevented, which can enhance the reliability and stability of the memory

cell.

Login to View More

Login to View More  Login to View More

Login to View More