Solid-state imaging device and method of producing solid-state imaging device

a solid-state imaging and imaging device technology, applied in the direction of radioation controlled devices, television system scanning details, television systems, etc., can solve the problems of dark current generation, efficient attraction, and achieve sufficient negative band-bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0024](Embodiment in which Oxide Insulating Film is Composed of Metal Oxide)

[Structure of Solid-State Imaging Device]

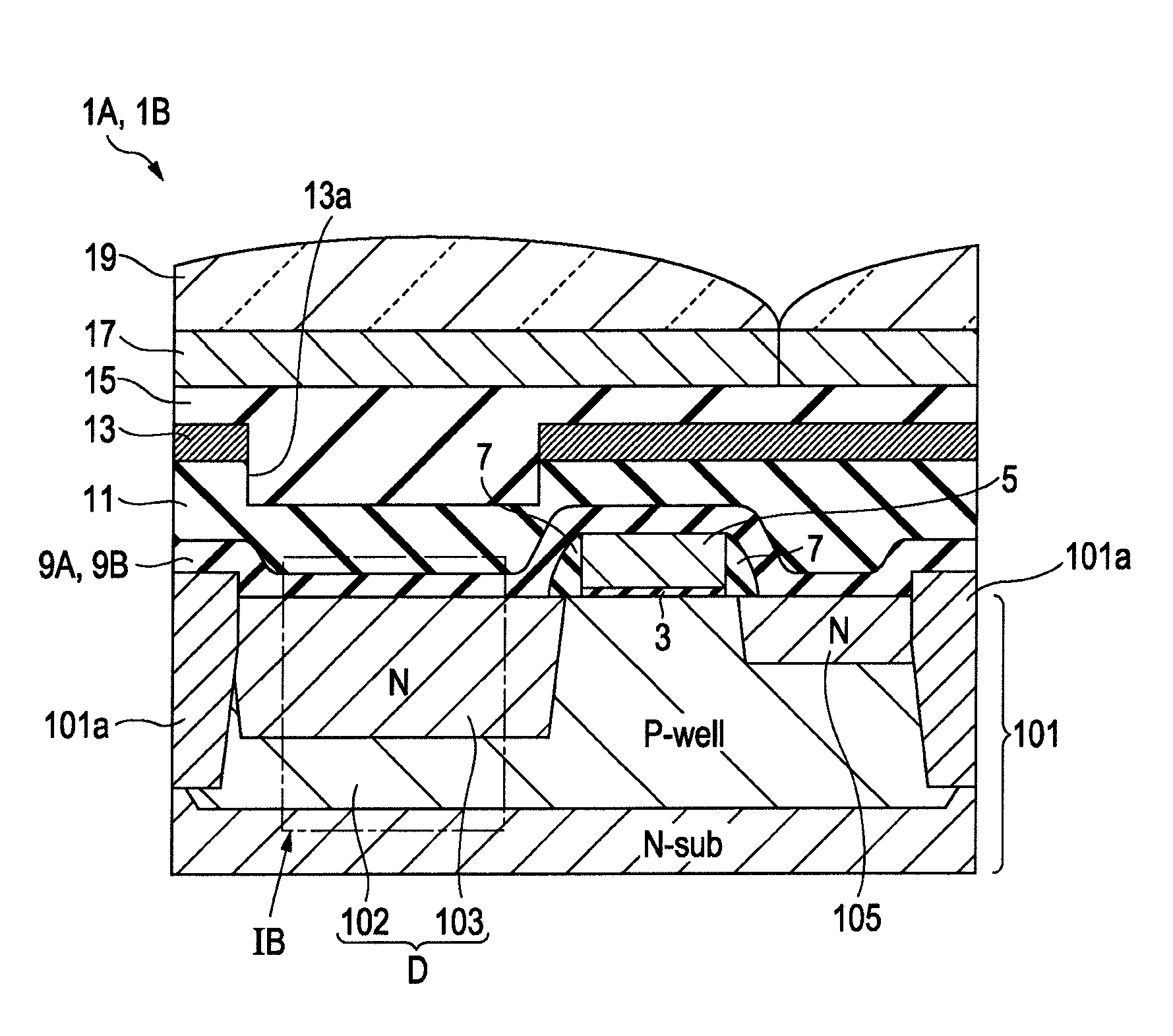

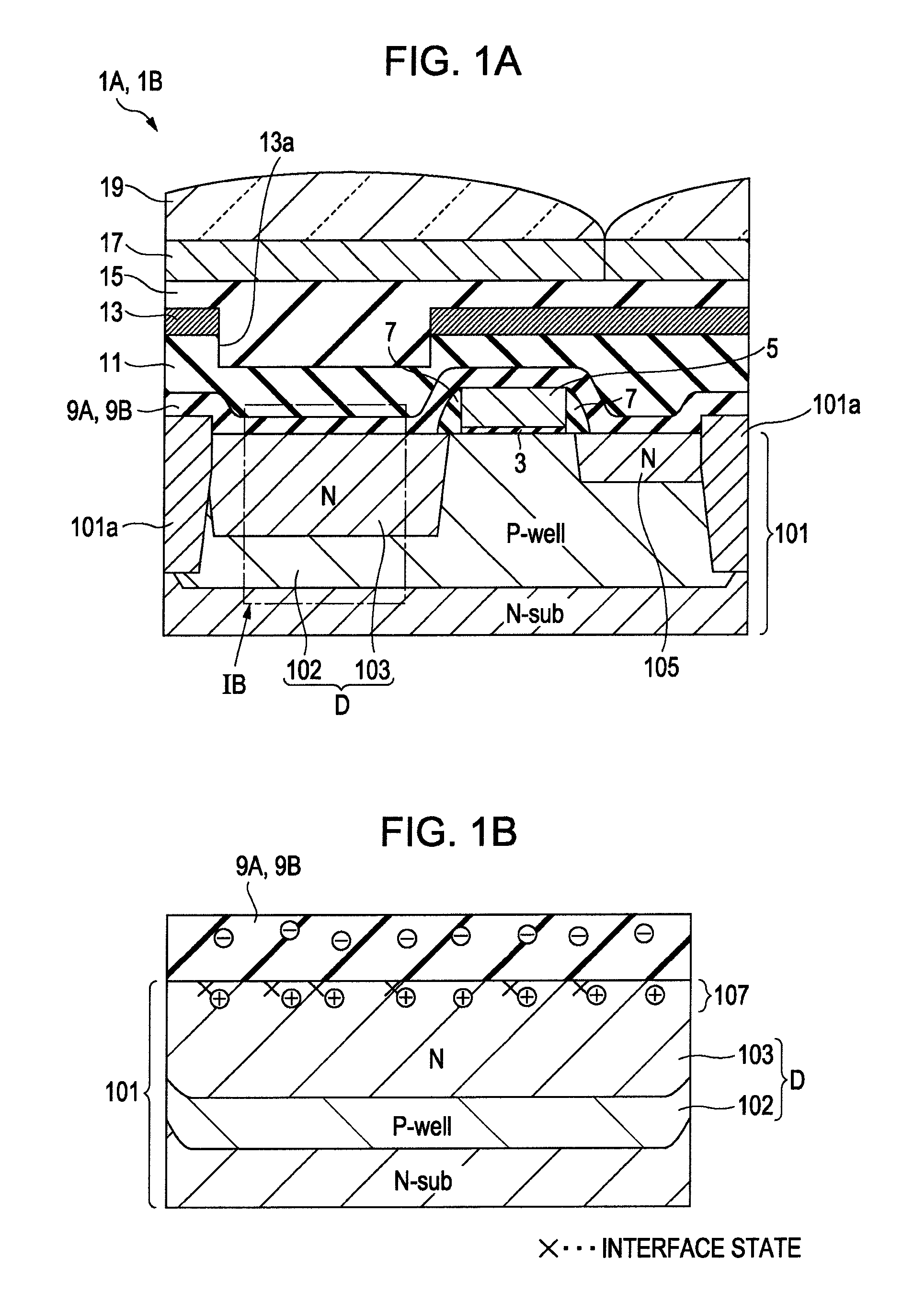

[0025]FIG. 1A is a cross-sectional view of a relevant part of one pixel in the case where a solid-state imaging device according to an embodiment of the present invention is applied to a CMOS sensor. FIG. 1B is an enlarged view of portion IB of FIG. 1A. A solid-state imaging device 1A of a first embodiment shown in FIGS. 1A and 1B has the following structure.

[0026]On a surface side of a semiconductor substrate 101 composed of N-type single-crystal silicon, for example, trench element isolations 101a (shallow trench isolations: STI) are provided to isolate each pixel region. A P-well diffusion layer 102 is provided on the surface side of the semiconductor substrate 101 in each pixel region isolated by the element isolation regions 101a. A transfer gate 5 is pattern-formed on the semiconductor substrate 101 with a gate insulating film 3 therebetween, so as to intersect ...

second embodiment

[0065](Embodiment in which Oxide Insulating Film is Composed of Silicon-Based Material)

[Structure of Solid-State Imaging Device]

[0066]A solid-state imaging device of a second embodiment differs from the solid-state imaging device 1A of the first embodiment described with reference to FIGS. 1A and 1B in the structure of the oxide insulating film, and the other structures of these solid-state imaging devices are the same as each other. The structure of a solid-state imaging device 1B of the second embodiment will now be described with reference to FIGS. 1A and 1B.

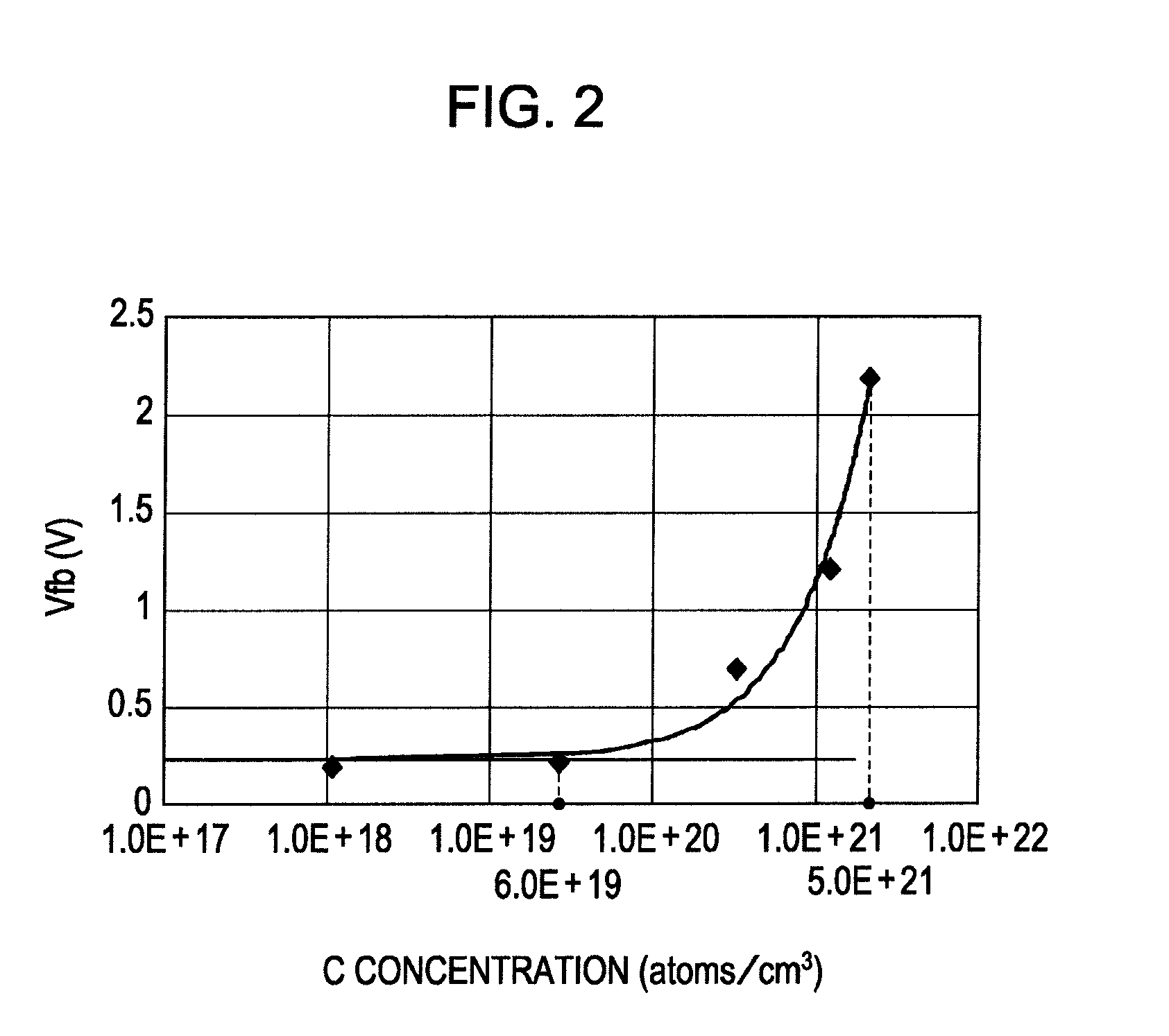

[0067]Specifically, in the solid-state imaging device 1B of this second embodiment, a semiconductor substrate 101 including element isolations 101a, a transfer gate 5, a diode D, a floating diffusion portion 105, and transistors constituting a drive circuit is covered with an oxide insulating film 9B composed of a silicon-based material. This oxide insulating film 9B contains carbon, and accordingly, as in the first embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com