Inspection of underfill in integrated circuit package

a technology of integrated circuits and which is applied in the direction of gas flame welding apparatus, instruments, image data processing, etc., can solve the problems of reliability issues of ic packages, and achieve the effect of effective and efficient inspection of underfill materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

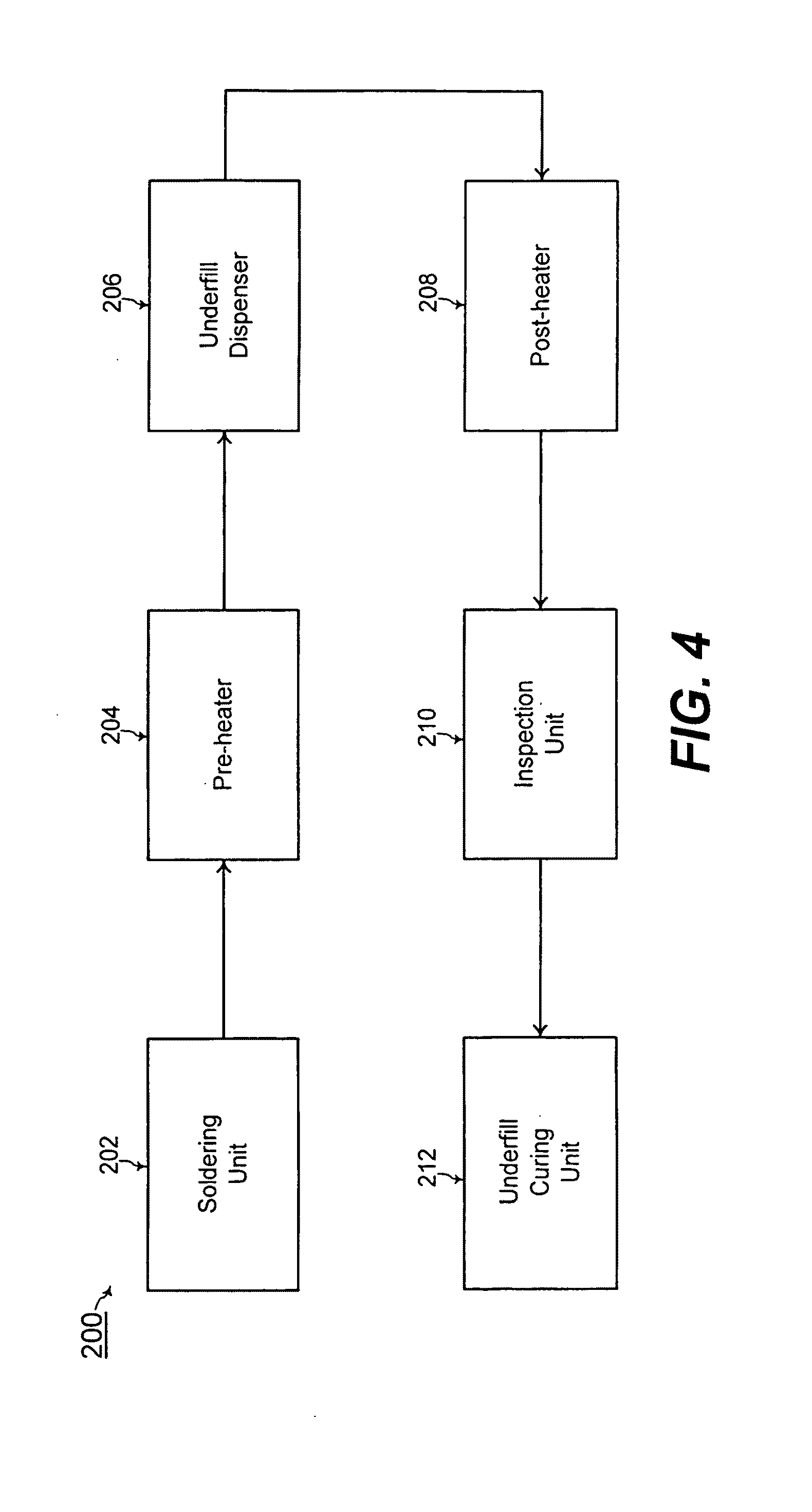

[0031]FIG. 4 shows a system 200 for properly dispensing underfill material during manufacture of an IC package. The system 200 includes a soldering unit 202, a pre-heater 204, an underfill dispenser 206, a post-heater 208, an inspection unit 210, and an underfill curing unit 212. FIG. 5 shows a flow-chart of steps during operation of the system 200 of FIG. 4.

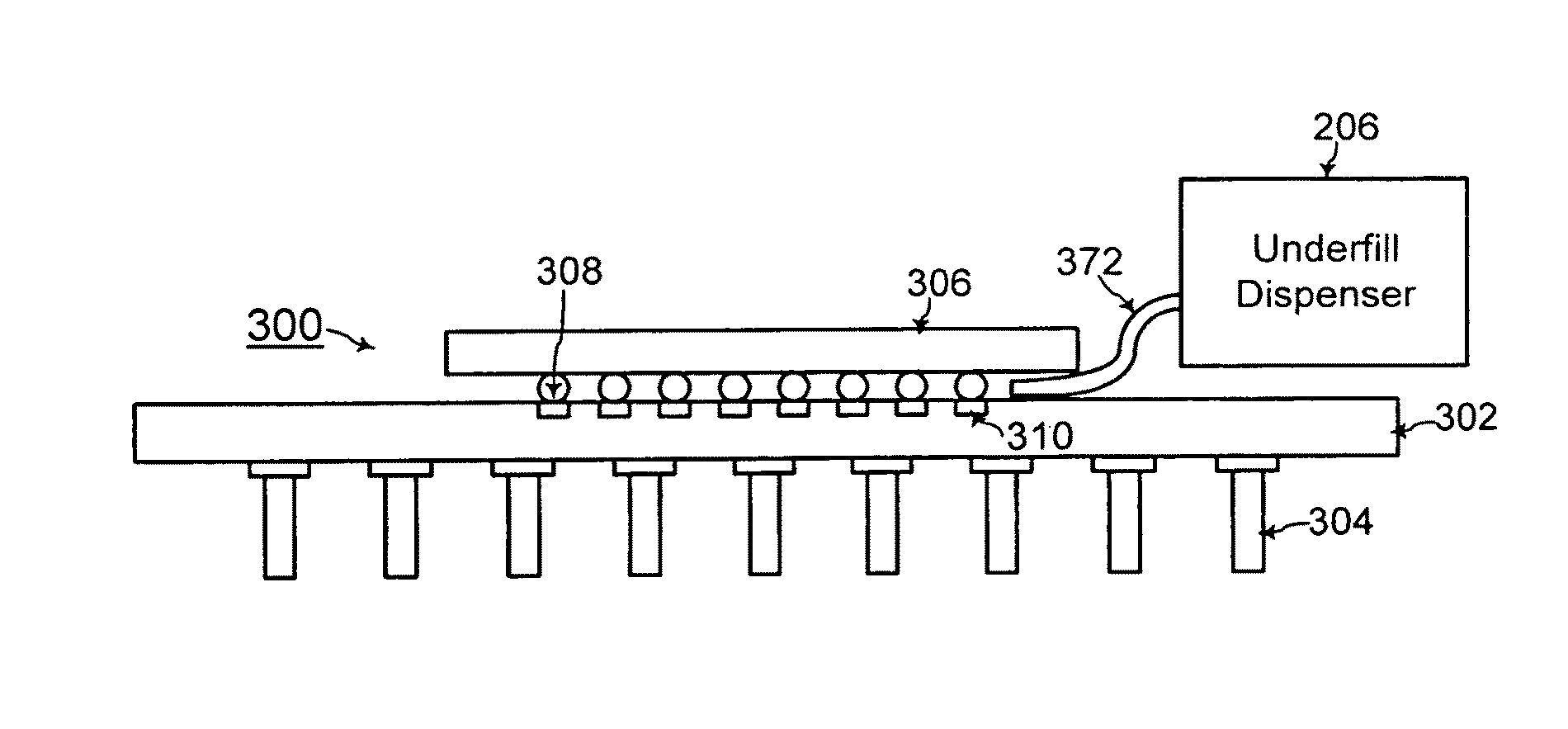

[0032]FIG. 6 shows an example IC package 300, such as a flip-chip IC package for example, processed through the system 200 of FIG. 4. The IC package 300 of FIG. 6 includes a package substrate 302 that supports pins 304 for providing electrical coupling to nodes of an integrated circuit (IC) die 306. Contact balls 308 and contact pads 310 on the substrate 302 couple such nodes of the integrated circuit die 306 to the pins 304 of the substrate 302.

[0033]The soldering unit 202 couples the contact balls 308 from the IC die 306 to the contact pads 310 of the substrate 302. For example, the contact balls 308 are soldered to the contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tilted angle | aaaaa | aaaaa |

| tilt angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com