Pit road display

a technology for pit roads and gauges, applied in the direction of instruments, transportation and packaging, instrument arrangements, etc., can solve the problems of driver division of attention, driver risking losing position in a race, and lapse in attention can have catastrophic consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

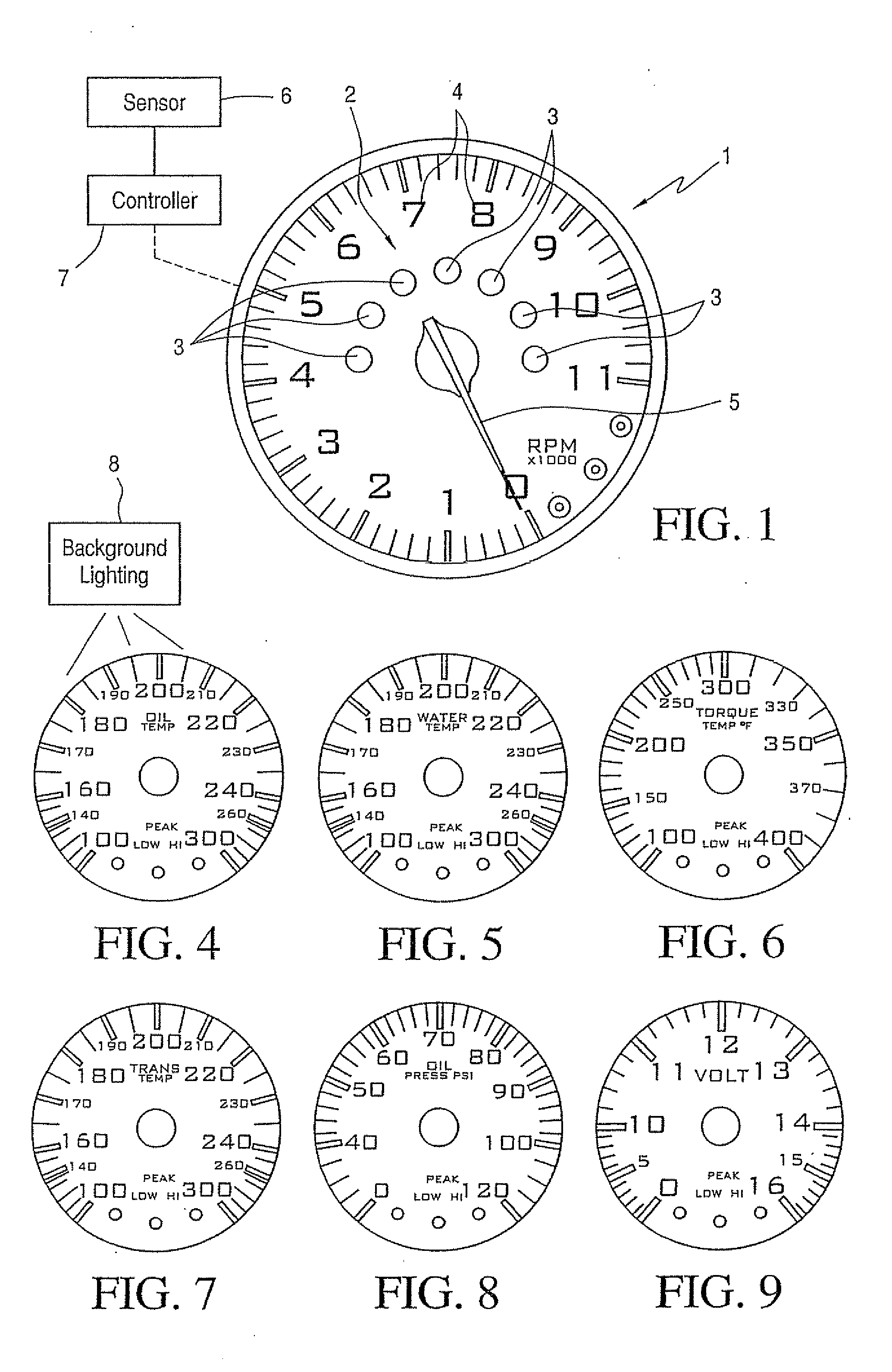

[0044]FIG. 1 shows a tachometer 1 having a secondary display 2 that includes seven indicator lights 3 arranged to be successively illuminated in order to indicate shift points. The seven indicator lights 3 are preferably in the form of multi-color LEDs having a brightness sufficient to enable the lights to be seen using the driver's peripheral vision. The lights 3 may be progressively illuminated such that the leftmost light will be illuminated first, followed by the leftmost light and the adjacent light, followed by the leftmost three lights, and so forth until all seven lights are illuminated. This pattern of progressive illumination may be referred to as a progressive illumination sequence. Preferably, three such progressive illumination sequences are provided, including a first in which the lights being illustrated are all green, a second in which the lights being illuminated are all yellow, and a third in which the lights being illuminated are all red,

[0045]The tachometer also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com