Thermal control of deposition in dip pen nanolithography

a technology of nanolithography and thermal control, which is applied in the field of thermal control of deposition in dippen nanolithography, can solve the problems of loss of registry between the tip and the surface, the inability of the coated tip to be used for imaging purposes, and the further limitation of dpn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

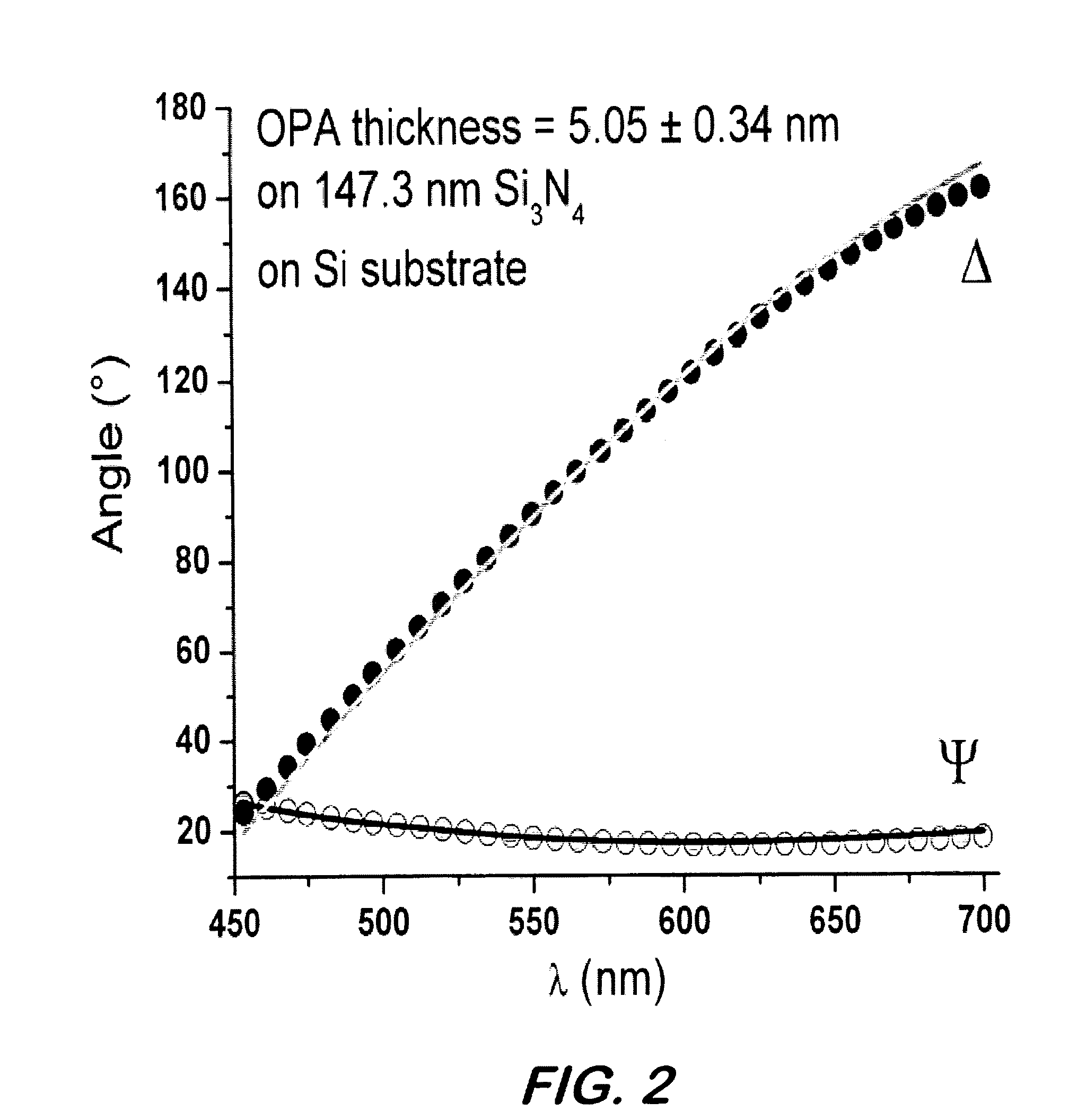

[0039]Deposition of OPA—An AFM tip, coated with OPA in the manner described above, was rastered over four, 500 nanometer square regions on a mica substrate at 2 Hz and 128 lines per scan, or for a total scan time of 256 s. For each square, the temperature of the cantilever was increased, finally exceeding OPA's melting temperature. When the temperature of the tip was held below OPA's Tm, either at 25° C. or at 57° C., no patterned squares were observed. Raising the tip temperature to 98° C., near OPA's Tm, resulted in light deposition. The average height of this area was 1.1 nm, which is slightly less than one-half the height of a full monolayer. Robust deposition was finally seen when the cantilever temperature was raised to 122° C., creating a square pattern with a height of 2.5 nm, indicative of a full monolayer, as shown in FIG. 3. The corresponding friction image, shown in FIG. 4, confirms OPA deposition. The binding of OPA to mica exposes a methyl terminal group, which would r...

example 2

[0042]Deposition of PDDT—tDPN was used to deposit conducting polymer between electrodes. The polymer was poly(3-dodecylthiophene) (PDDT), a semiconducting polymer useful for organic FETs. The tip was heated to ˜200° C. under nitrogen (to avoid oxidation). The tip was then scanned from one electrode to the other for 2 minutes. The deposited line was 20 nm thick and 150 nm wide and spaned an 800 nm wide gap.

example 3

[0043]Deposition of Indium—For the repair of nanoscale circuits or of the photomasks used to make modem circuitry, it is important to be able to write small, conducting wires. tDPN was used to pattern indium, a low melting point metal and a common solder. FIG. 7 shows a series of 3 μm lines written at a tip speed of 3 μm / s. Each line was traversed 64 times (i.e., 32 trace / retraces) by the depositing tip. The top two lines written at 95° C. and 135° C. do not show, the faint line at bottom left was written at 156° C. which is close to the melting temperature of the indium, 156.6° C. The line at bottom right was written at 196° C., which is well above the melting temperature of indium, and demonstrates robust deposition at this temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperatures | aaaaa | aaaaa |

| room temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com