Ceramic dental implant

a ceramic dental implant and ceramic technology, applied in dental implants, dentistry, dentistry, etc., can solve the problems of affecting the the inability to realize the screw connection between metal (titanium anchoring part) and ceramic (mounting part), and the inability to pervade parts made of ceramic, etc., to achieve the effect of high mechanical stability of the total system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

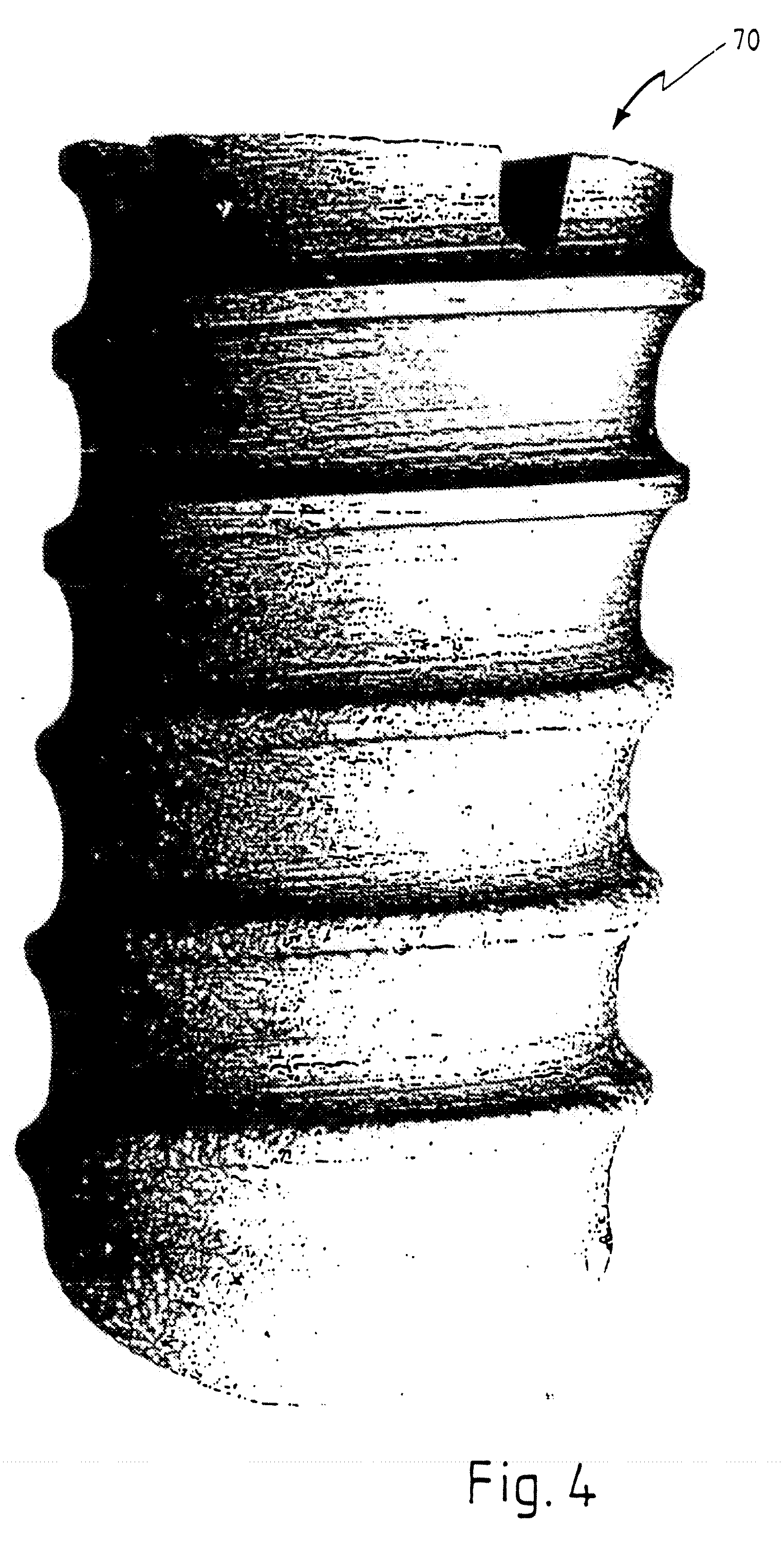

[0081]Test implant specimen according to FIG. 4 were prepared from a zirconia ceramic according to U.S. Pat. No. 6,165,925 and were processed by grinding to yield the shape according to FIG. 4.

[0082]Thereafter, the surface of the specimen was sand blasted with corundum using a blasting pressure of 4 bars. This yielded a maximum surface roughness of 6.4 μm with an average surface roughness of about 4.7 μm.

[0083]The test implant sample 70 shown in FIG. 4 was implanted into a patient. After a healing time of about 3 months the test implant sample was removed together with a small amount of the surrounding bone material using a hollow drill and was analyzed histologically with respect to osteointegration. It was found that an integrating osteogenesis can be reached.

[0084]Additional improvements with respect to an integrating osteogenesis already after short healing time are particularly expected when using increased surface roughness in the range of about 5 to 15 μm Rmax which may be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com